Grout-Filled Mattresses Applications and Geotextile Mattress Uses

Key Takeaways

- • Erosion Control: Geotextile grout-filled mattresses are primarily used to stop soil erosion in rivers, canals, coastlines, and channels. They are real good at this.

- • Scour Protection: They protect underwater structures like bridge piers and pipelines from being undermined by water flow.

- • Slope Stability: These systems help stabilise slopes, preventing landslides, especially alongside roads or railways. Sometimes they use special ones for vegetation support.

- • Channel Lining: Used to line ditches and channels, ensuring water flows smoothly and dont cause more erosion.

- • Infrastructure Protection: They provide durable protection for critical infrastructure in various water-related environments. You can find proven projects showing this.

- • Flexibility: The system conforms to uneven surfaces before grouting, unlike rigid solutions. Its pretty adaptable.

- • Durability: Once filled with grout, the mattress forms a tough, long-lasting protective layer. These things can really transform terrains.

What Exactly Are Geotextile Grout-Filled Mattresses?

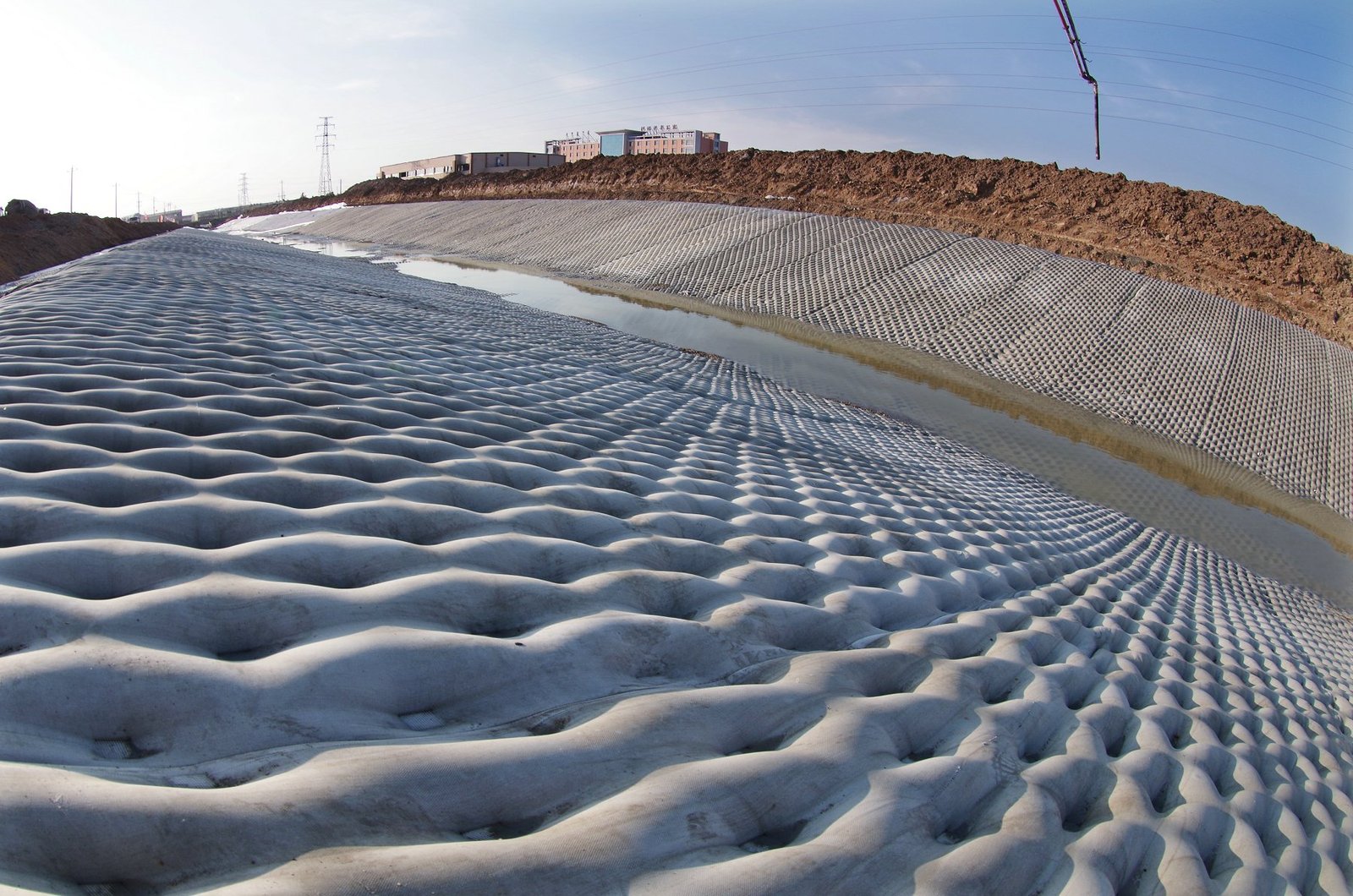

So, what’re we talkin’ about here? Geotextile grout-filled mattresses are basically engineered blankets. They’re made from two layers of tough synthetic fabric, like polypropylene or polyester, stitched together in a specific pattern. Think of it like a big, flat bag with compartments sewn in. This fabric structure acts as a flexible formwork. On site, you lay this fabric mattress down where you need it – could be a riverbank, could be under a bridge, lotsa places – and then you pump a specialized cement grout mix into it. The grout fills up all them compartments, expands the mattress to its designed thickness, and then hardens. What you end up with is a solid, heavy, yet somewhat flexible concrete slab thats locked into the shape of the ground underneath. It’s a clever bit of kit, really.

The magic is in the geotextile fabric itself. It has to be strong enough to hold the wet grout without bursting, but porous enough to let excess water from the grout mix seep out slowly. This dewatering actually helps the grout cure stronger and quicker, kinda like wringing out a sponge helps it dry. The fabric patterns aren’t random either; they control the final shape and thickness. Some have filter points built in, designed to let groundwater pressure release without washing away the soil underneath – these are often used in advanced filtration geotextile mattress systems. Others might have a raised pattern, which can offer cost savings according to some data on raised-pattern systems possibly cutting costs. The whole idea is to create a stable, erosion-resistant surface thats tailor-made for the spot its put in. Been workin’ with these things for years, and their adaptability always impresses me. You can learn more about the basic uses, construction, and benefits in this guide. Its a pretty foundational piece of modern civil engineering, especially around water.

Stopping Erosion Dead in Rivers and Canals

One of the biggest uses for these mattresses, probably the most common one I seen in my time, is controlling erosion along rivers and man-made canals. Water, especially when it’s flowing fast or changing levels a lot, it just loves to eat away at banks. Over time, this can undermine structures, widen channels unnaturally, and dump a load of unwanted sediment downstream. Traditional methods like riprap (just dumping big rocks) can work, but sometimes the rocks are too small for the flow, or they shift about, or they’re just plain unavailable or too costly to transport. Geotextile mattresses offer a really solid alternative. You lay ’em down along the bank, conforming to its curves and dips, pump ’em full of grout, and bam – you got a continuous, armored surface that water struggles to get a grip on.

We’ve used these on countless projects, from small stream restorations to major canal linings. I remember one job on a particularly bendy river; the outer bank was getting hammered during high flows. Riprap just kept getting washed away. We came in with a geotextile mattress solution, tailored the panel layout to fit the curve perfectly. Once it was grouted, that erosion point was just… stopped. The flexibility of the fabric before grouting is key here; it lets you get a snug fit against the existing bank profile, much better than trying to place rigid blocks. And because the final slab is articulated – meaning it has some give due to the fabric joints between grout pockets – it can handle a bit of settlement or movement without cracking apart like a solid concrete pour might. This makes them particularly good for areas with slightly dodgy ground conditions. You can see some examples of the kinds of water infrastructure projects where these are vital. The advantages for erosion control are really significant compared to older methods, especially lookin’ at long-term performance and reduced maintenance.

Protecting Our Coasts and Shorelines

Coasts are rough environments, no doubt about it. Constant wave action, tidal currents, storm surges – they all put immense pressure on shorelines. Coastal erosion is a massive problem globally, threatening property, infrastructure, and natural habitats. Geotextile grout-filled mattresses are a powerful tool in the coastal engineer’s arsenal for fighting this. They get used in a few different ways here. Often, they form the primary armor layer for seawalls or revetments, absorbing and dissipating wave energy before it can chew away at the land behind. They can also be laid on the seabed in front of coastal structures to prevent undermining, or toe scour, which is a common failure mode. Because they can be manufactured in large panels and sunk into place, they’re quite efficient for underwater work too, though access is always a bit of a challenge out there, innit?

What I like about ’em for coastal work is how they handle the dynamic nature of the coast. Unlike rigid concrete structures that can be undermined or outflanked if the seabed changes shape, a mattress installation has that bit of flexibility. It can settle slightly with the seabed without losing its integrity. We’ve specified them for protecting the foundations of breakwaters and jetties, and also just for direct shoreline armoring on sandy coasts where rock isn’t practical. Sometimes, specialized designs are needed, maybe incorporating features to encourage marine habitat or using extra-heavy-duty fabrics and specific grout mixes to withstand really high wave forces. These projects often involve protecting critical infrastructure, so gettin’ the design right is paramount. There’s related technologies too, like the Techrevetment formed concrete mattresses mentioned by some suppliers, which operate on similar principles of using fabric forms. Getting the installation timed right with tides is crucial, a lesson learned the hard way on a project down south few years back – misjudged the window and had a half-filled panel tryin’ to float away on us! It highlights the need for experienced crews.

Preventing Scour Around Underwater Structures

Scour is a sneaky enemy for anything built in water. Bridge piers, pipeline crossings, offshore wind turbine foundations – they all obstruct the natural flow of water. This causes the water to speed up and swirl around the obstruction, digging away at the riverbed or seabed material that supports the structure. If it goes unchecked, this scour process can literally undermine the foundations, leading to instability or even catastrophic failure. Geotextile grout-filled mattresses are a go-to solution for preventing this. By placing a mattress around the base of the structure, you essentially armor the bed material, preventing the water currents from eroding it away. Its like putting a protective collar around the foundations.

Installing these things underwater obviously has its own set of challenges. Visibility can be poor, currents can make precise placement tricky, and you need dive teams or remotely operated vehicles (ROVs) for inspection and sometimes positioning. However, the flexibility of the unfilled mattress is again a big plus; it drapes over uneven beds much better than trying to place precast concrete blocks, for example. The grout is typically pumped down from a barge or the structure itself. We’ve seen these used extensively on proven water infrastructure projects, protecting everything from highway bridge piers in fast-flowing rivers to crucial subsea pipelines carrying oil and gas. The mattress needs to extend far enough out from the structure to cover the potential scour zone, which often requires careful hydraulic modeling beforehand to predict how deep and wide the scour hole might get without protection. The concept is similar in ways to general fabric formed concrete techniques, but highly specialized for this scour protection role. Had a project once where unexpected debris on the seabed made placement difficult; it just shows you gotta do thorough surveys before you start pumpin’ grout.

Stabilizing Slopes and Stopping Landslides

Moving away from constantly wet environments, these mattresses also do a cracking job on dry land, specifically on slopes. Steep embankments alongside roads, railways, or building sites are prone to surface erosion from rain splash and runoff, and sometimes even shallow landslides, especially after heavy rainfall. A geotextile mattress, laid over the prepared slope surface and grouted, creates a hard, protective crust that stops this erosion cold. It essentially armors the slope face, preventing soil particles from being washed away and holding the surface layer together. This is super important for maintaining the safety and integrity of transport corridors and other bits of critical infrastructure.

A particularly neat application here involves using specialized mattresses designed to work with vegetation. These are often called vegetation geotextile mattress systems. They have un-grouted pockets or openings specifically designed to be filled with topsoil and seeded after the main grout voids are filled. So, you get the immediate erosion protection from the grouted sections, but over time, plants establish in the soil pockets. Their roots grow through the fabric and into the soil beneath, providing additional long-term stabilization and also making the slope look a heck of a lot nicer and greener. It’s a great combination of hard engineering and natural solutions. Seen this used brilliantly on highway cuttings where aesthetics were important, but they still needed that robust protection straight away. Placement on steep slopes requires careful anchoring at the crest, of course, and managing the grout flow downhill needs a bit of skill to ensure even filling without blowouts at the bottom. These things really help transform terrains that might otherwise be unstable or prone to erosion.

Lining Channels and Protecting Ditches

Drainage channels, irrigation canals, stormwater ditches – they’re all designed to move water from A to B. But the act of moving that water, especially if it’s flowing fast or carrying sediment, can cause erosion within the channel itself. This can lead to the channel silting up, losing its capacity, or undermining its own banks. Lining these channels with a protective layer is often necessary, and geotextile grout-filled mattresses are an excellent option, especially for larger or more critical channels where simple grass or loose rock isn’t enough. Laying a mattress along the bed and sides of a channel provides a smooth, durable, and erosion-resistant surface. It effectively locks the channel profile in place.

The benefits here are pretty clear. You maintain the hydraulic efficiency of the channel – water flows better over the smooth, grouted surface than it does over rough rock or erodible earth. This helps prevent flooding and ensures water gets where it needs to go, particularly important in irrigation schemes. It also drastically reduces maintenance costs associated with dredging silt or repairing eroded banks. Some designs, like advanced filtration geotextile mattress systems, can be important here too, allowing groundwater to seep into the channel without causing instability. And as mentioned before, certain types like the raised-pattern mattresses claim significant cost savings compared to alternatives, potentially up to 40%, which is always attractive for project budgets. I’ve seen these used in everything from agricultural drainage networks to large concrete-trapezoidal channels carrying urban stormwater runoff. They provide a really robust lining that stands up to flow velocities that would strip out vegetation or even smaller riprap. Getting the overlaps between panels right is key for channel lining, ensuring a continuous protective layer without weak spots where erosion could restart.

Environmental Uses: Landfill Lining and Caps

You might not immediately think of landfills when discussing erosion control, but managing water and preventing soil movement is critical in waste containment systems. Geotextile grout-filled mattresses find niche but important applications here, particularly in capping systems and sometimes within the liner components. When a landfill cell reaches capacity, it needs to be capped – covered with layers of soil and impermeable membranes to prevent rainwater infiltration (which creates contaminated leachate) and control gas emissions. The final cover often includes steep slopes, which are susceptible to erosion from wind and rain before vegetation fully establishes. Laying a mattress over vulnerable parts of the cap, especially drainage channels or downchutes designed to carry rainwater off the cap safely, provides immediate and long-lasting erosion protection. This protects the integrity of the underlying barrier layers, which is vital for environmental safety.

The mattress essentially armors these drainage pathways, ensuring runoff gets off the cap quickly without scouring channels that could eventually breach the cap system. In some cases, they might also be used on internal slopes within the landfill, perhaps to protect temporary cover layers or access roads. Given the environmental sensitivity, specifying the right materials and ensuring quality installation is crucial. This ties into the push for clearer standards, like the new specification for geotextile grout-filled mattresses discussed in industry publications. While maybe not as common as riverbank protection, this application shows the versatility of the technology. Thinking about the bigger picture, managing waste effectively and preventing pollution is linked to broader sustainability goals, touching on complex issues like the relationship between economic growth and environmental impact. Using robust engineering solutions like these mattresses plays a small but important part in responsible environmental management. You can find more general info on uses and construction within this geotextile mattress guide.

A Word on Installation and Why Experience Matters

Alright, so we’ve talked about where you use these things, but how they go in deserves a mention too, ’cause it ain’t always simple. The basic process sounds straightforward: prepare the ground, lay out the fabric mattress, connect the inflation ports, pump the grout, let it cure. Easy peasy, right? Well, sorta. The devil, as they say, is in the details. Getting the ground prep right is essential – it needs to be relatively smooth, without sharp rocks or voids that the mattress just bridges over. Then, laying out large fabric panels, sometimes underwater or on steep slopes, requires careful handling and positioning. You gotta make sure overlaps are correct and anchor trenches (if needed) are properly dug. The manufacturing process itself creates these large, sometimes cumbersome panels.

The grouting stage is where real skill comes in. The grout mix design is critical – gotta be flowable enough to pump easily and fill every nook and cranny, but not so wet that it just separates or takes forever to gain strength. You need to control the pumping pressure carefully; too high and you risk bursting the fabric seams (seen it happen!), too low and you might not fill the mattress completely, leaving weak spots. Monitoring the fill progress across the whole panel is important, especially on large installations. Temperature plays a role too – grout behaves differently in hot weather versus cold. Having an experienced crew, guys who’ve done this before and know what to look for, makes a massive difference to the final quality of the job. They know the little tricks, like how to manage the pump lines, how to vent trapped air, how to check for full inflation. It’s this practical know-how that ensures these durable geotextile mattresses actually perform as designed for years to come. It’s not just about the product; the installation quality is just as important for these systems.

Frequently Asked Questions (FAQs)

Q1: How long do geotextile grout-filled mattresses typically last?

A: When properly designed and installed for the specific site conditions, these mattresses are very durable. They’re essentially creating a concrete structure reinforced with geotextile. Lifespans of several decades (30-50 years or more) are commonly expected, especially in less aggressive environments. The actual lifespan depends on factors like water flow velocity, potential abrasion, UV exposure (if not underwater or covered), and the quality of the grout and installation.

Q2: Can vegetation grow through or on these mattresses?

A: Standard mattresses form a solid concrete surface that generally prevents vegetation growth. However, specific vegetation geotextile mattress systems are designed with openings or pockets intended to hold soil and allow plants to establish, combining hard armor protection with ecological benefits.

Q3: Are they environmentally friendly?

A: Compared to some alternatives like mass concrete or very large quarried rock (which has transport impacts), they can be considered relatively low-impact. The geotextile itself is synthetic, but the main component by volume is the cement grout. The installation avoids major excavation in many cases. Using vegetated options enhances habitat value. However, concrete production does have a carbon footprint, which is a consideration, kinda like the points raised in discussions about growth vs environment.

Q4: How flexible are the mattresses after the grout cures?

A: They lose the initial fabric flexibility once grouted, becoming a rigid concrete slab. However, because the mattress is formed from interconnected filled pockets (like a quilt), the overall system retains some articulation. This means it can tolerate minor ground settlement or adjustments better than a single, large, unreinforced concrete pour might, which could crack significantly. The degree of articulation depends on the mattress pattern.

Q5: What are the main advantages over traditional riprap?

A: Key advantages include:

- Consistent thickness and interlocking: Provides a more stable and less permeable layer than loose rock.

- Flexibility during installation: Conforms better to uneven ground before grouting.

- Hydraulic efficiency: Often provides a smoother surface for better water flow in channels.

- Controlled quality: Manufactured product with specific properties, unlike variable natural rock.

- Potential for vegetation: Specific designs allow integration with plants.

- Sometimes more cost-effective, especially if suitable rock isnt available locally. Check out the potential advantages here.