Coastal Erosion Control Projects and Riverbank Restoration Success

Key Takeaways

- Geotextile mattresses provide effective, real-world solutions for erosion on coastlines and riverbanks.

- Projects show these systems stabilise shorelines, protect infrastructure, and can even support vegetation growth.

- Different mattress types, like filtration and vegetation systems, address specific site needs.

- Raised-pattern geotextile mattresses offer significant cost savings compared to traditional methods.

- Proper installation is key for long-term success; expert guidance is valuable.

- These solutions are increasingly important for building resilience against environmental changes, as seen in various coastal defense projects.

Introduction: Tackling Erosion on Coasts and Rivers

Right, let’s talk about erosion. It’s a massive headache along our coasts and riverbanks, ain’t it? You see land just washing away, littorally disappearing over time. It ain’t just about losing pretty views; it threatens homes, roads, farmland, the whole lot. I’ve been working in this field for donkey’s years, seen firsthand how a churning river or relentless waves can undercut a bank. One season it looks fine, next season half the bank’s gone downstream. It’s a natural process, sure, but human activity and bigger storms seem to make it worse nowdays. We build closer to the water, change how water flows, and then act surprised when the land gives way. Finding good ways to stop it, or at least slow it down, is proper important. Traditional methods like concrete walls or piles of rock (riprap, we call it) can work, but they’re often expensive, ugly, and sometimes cause problems further down the coast or river. Plus, hauling all that material can be a nightmare logistically. We need somethin’ smarter, more adaptable. That’s where newer tech comes in, stuff designed to work with the environment a bit more. Understanding the basics is key, like what you’d find in a good Geotextile Mattress Uses, Construction, Benefits & Installation Guide. It’s not just about dumping material; it’s about engineering a stable edge that holds up.

Think about the forces involved. Water’s heavy stuff, and when it moves fast, it carries immense power. It picks up soil particles, undermines banks, scours channels. On the coast, waves smash against the shore day in, day out. Add storm surges on top, and the potential for damage is huge. Just look at the efforts after big events like Superstorm Sandy, the scale of repair needed shows how vulnerable some areas are. Riverbanks face similar issues, ‘specially during floods. Fast flows can rip out vegetation, erode bends, and threaten bridges or buildings nearby. It’s a constant battle. Finding solutions that last, that don’t cost the earth (literally and financially), and ideally look okay too… well, that’s the goal. It requires a good understanding of the site, the specific erosion problems, and the best tools for the job. You can’t just chuck any old thing at it and hope for the best. It takes careful planning and the right materials. We’re talkin’ engineered solutions designed for these tough environments.

Geotextile Mattresses: A Game Changer for Shoreline Stability

So, what are these geotextile mattresses then? Basically, they’re engineered fabric containers, usually made from tough synthetic materials. Think of ’em like big, flat, specially designed bags. You lay them out on the slope you wanna protect – could be a riverbank, could be a coastal dune, could be the side of a canal. Then, you fill ’em, usually with concrete or mortar grout pumped in under pressure. The fabric acts as the formwork, containin’ the fill and giving the mattress its shape. Once that fill sets, you’ve got a durable, flexible, and permeable protective layer right there on the surface. It armours the soil underneath against the erosive forces of water. It’s a way to Transform Terrains with Durable Geotextile Mattresses. I’ve seen these things installed in all sorts of conditions, and they’re remarkably effective when done right. The key is the combination of strength from the fill and the specific properties of the geotextile fabric itself. It’s not just any old cloth; it’s designed to let water pressure escape from behind (reducing uplift forces) while holdin’ back the soil particles. That permeability is dead important, summat you don’t get with solid concrete walls.

One of the big Advantages and Applications of Geotextile Mattresses in Erosion Control is their flexibility. Unlike rigid structures, they can conform to uneven ground and handle a bit of settlement without cracking apart. This makes ’em brilliant for unstable soils or areas prone to minor shifts. They’re also generally quicker and less disruptive to install compared to pouring large volumes of concrete or quarrying and transporting massive rocks. You bring the fabric rolls and the grout pump to site, which is often easier logistically. Different types exist too, tailored for specific jobs. Some are designed purely for armouring, others have features to encourage plant growth, helping the site blend back into the natural environment faster. Some even have special filtration properties. It’s about choosing the right tool for the specific problem you’re tryin’ to solve along that river bank or coastline. Getting that choice right is half the battle.

Case Study 1: Restoring a Major Riverbank with Filtration Systems

Right, picture this: a big river, fast flowin’, especially after rain. One particular bend was gettin’ hammered year after year. The outside bank was just crumbling away, threatening a nearby access road and some utility lines buried alongside it. Traditional riprap had been tried before, but the smaller stones just got washed away in floods, and bringing in massive boulders was gonna be hugely expensive and disruptive. Plus, there were concerns about water quality and seepage from the bank itself. This is where specialized systems come into their own. We looked at using Advanced Filtration Geotextile Mattress Systems for this job. Why filtration? Because the bank wasn’t just eroding from the river flow at it, but also from groundwater seeping out of it, carrying fine soil particles with it. This internal erosion was destabilizing the whole thing. The filtration mattress is designed with a specific fabric structure. It lets the groundwater escape slowly, relieving the pressure, but the fabric pores are small enough to hold back the soil particles. Stops that internal washing-out dead in its tracks.

The installation involved grading the bank to a stable slope first – you always gotta prep the surface properly. Then the mattress units were laid out, overlapped, and stitched or pinned together. Anchor trenches at the top and toe (bottom) are crucial to stop the whole thing slipping or being undermined. Once the fabric ‘shell’ was in place, the concrete grout was pumped in. Watching it fill is quite satisfying, actually. You see the mattress plump up, taking its final shape. We used a relatively fluid mix so it flowed easily into all the corners. The key was controlling the pump pressure – too high and you risk bursting the fabric, too low and it won’t fill properly. Once cured, that bank was solid. The mattress formed a tough but slightly flexible armour layer. The river could flow past, even at high speed, and the bank material was protected. Crucially, the seepage issue was sorted too. Water could still get out, but the soil stayed put. It’s a good example of one of the many Proven Geotextile Mattress Projects for Water Infrastructure that show how effective these tailored solutions can be. Years later, that bank is still holding firm, the road’s safe, and the river’s flow hasn’t been negatively impacted elsewhere. Success, I’d call it.

Case Study 2: Coastal Defence Using Vegetation-Friendly Mattresses

Coastal erosion’s a different beast sometimes. You’ve got waves, tides, salt spray, and often sensitive dune ecosystems you wanna protect, not just armour. I remember workin’ on a project to stabilise a section of dune face that was getting badly eroded by winter storms. Just letting it go wasn’t an option because a coastal path and some infrastructure were right behind it. But putting down a solid concrete slab or a rock wall would’ve looked awful and destroyed the natural character of the area. Plus, environmental regs were strict about maintaining habitat. We needed somethin’ tough enough for the waves but also green. This led us straight to Advanced Vegetation Geotextile Mattress Systems for Slope Stability. These are clever bits of kit. They’re still fabric mattresses filled with grout, but they incorporate gaps or pockets within the structure specifically designed to be filled with topsoil and planted up after the main installation. The idea is, the mattress provides the immediate, hard protection against wave action at the toe of the dune, while the vegetation takes root in the pockets higher up the slope, eventually coverin’ the mattress and providing long-term ecological integration and stability. It’s a bit like the challenges faced by initiatives like NACo’s Coastal Counties Resilience Challenge, finding ways to protect communities while respecting the environment.

The install followed similar steps: careful grading, laying out the mattress sections, securing them, then pumping the grout. The difference was leaving those pockets unfilled by the concrete. After the grout cured, we came back and filled the pockets carefully with a suitable soil mix – had to be specified properly to retain moisture but also drain okay in that coastal environment. Then came the planting, using native dune grasses and salt-tolerant species known to thrive in that specific location. It took a season or two for the vegetation to really establish, but the results were brill. From a distance, you barely notice the underlying structure now. The plants took hold nicely, their roots further binding the soil in the pockets and adding another layer of stability. The mattress underneath does the heavy lifting when the big waves hit, preventing catastrophic erosion, while the vegetation provides the softer, greener finish and ecological benefits. It’s a fantastic example of combining hard engineering with soft, natural solutions. These kinds of projects are becoming more common as we look for ways to build resilient coastal projects that work with nature rather than just fighting against it.

The Role of Raised-Pattern Mattresses in Cost Reduction

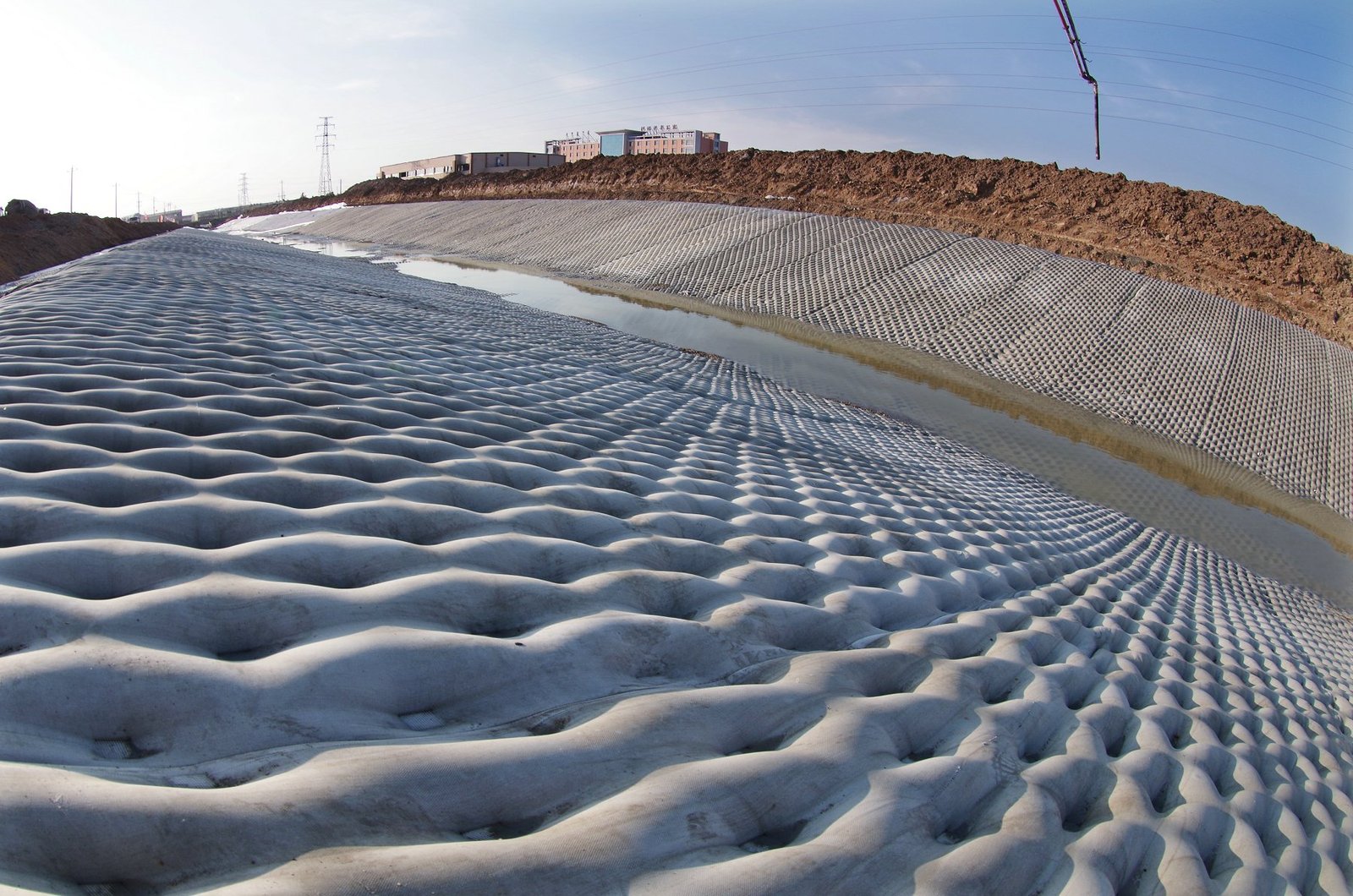

Now, let’s talk money. Big civil engineering projects, especially along waterways, can cost a packet. Materials, labour, transport, equipment hire – it all adds up mighty fast. Anything that can bring those costs down without compromising quality is gonna be looked at seriously. And that’s where one particular type of geotextile mattress shines: the Raised-Pattern Geotextile Mattress Systems Cut Costs 40%. Sounds like a sales pitch, I know, but the principle behind it is simple and it genuinely works in many situations. Instead of forming one continuous, thick slab of concrete like some older mattress types, these have a specific, engineered pattern woven or stitched into the fabric. Think of it like a quilt, but with high points and lower points. When you pump the grout in, it fills the ‘high’ parts to the full thickness, creating strong points and structural ribs. But in the ‘low’ or quilted points, the fabric layers are held closer together, so less grout is needed there.

So what’s the benefit? You’re using significantly less concrete grout overall to cover the same area compared to a uniform thickness mattress. Concrete’s often one of the biggest material costs in these jobs, so reducing the volume needed makes a direct impact on the bottom line. We’re talkin’ potentially savings of up to 40% on the grout volume, which is massive. This doesn’t mean it’s weaker, mind. The pattern is designed by engineers to maintain the necessary structural integrity and erosion resistance for the specific application. Those thicker ‘ribs’ provide the strength, while the thinner sections still protect the underlying soil. It’s an optimized design. Less grout also means faster pumping times, less weight (which can be important on softer ground), and a smaller carbon footprint from cement production and transport. I’ve specified these on several projects, particularly canal linings and moderate-flow riverbanks, where maximum armour thickness wasn’t the absolute priority, but reliable, long-term protection at a sensible cost was. The installation process looks pretty much the same as other types, as you can see in typical site photos showing workers laying out the fabric and preparing for the grouting phase. It’s just the internal structure of the fabric that’s different, leading to those savings.

Protecting Critical Infrastructure Along Waterways

One area where geotextile mattresses really prove their worth is protecting important stuff built near water. Think about bridge abutments and piers standing in a river. The constant flow, especially during floods, can scour away the riverbed material right around the foundations. If that scour gets too deep, it can undermine the structure, potentially leading to failure. It’s a huge safety risk and incredibly expensive to fix after the fact. Same goes for pipelines crossing under rivers, or outflow structures, or intake pipes for power stations or water treatment plants. They all need protection from erosion and undermining. Providing Specialized Geotextile Protection for Critical Infrastructure is a core application for these systems. Geotextile mattresses offer a way to armour the riverbed or bank right next to the structure. You can lay them around bridge piers or wrap them over pipelines buried in the channel bed. Once filled with grout, they create a stable, non-erodible layer that prevents the water from washing away the supporting soil.

I worked on a project protecting the foundations of an old railway bridge. The river currents were particularly strong there, and inspection dives showed significant scour pockets forming around the main piers. We couldn’t risk the bridge’s stability. Closing the line for major underwater concrete work would’ve been chaos. Instead, we used custom-shaped geotextile mattresses designed to fit snugly around the base of each pier, extending out onto the riverbed. Divers helped position them correctly, then we pumped them full of grout from a barge. It was way faster and less disruptive than traditional underpinning methods. The mattresses basically formed a protective ‘apron’ around the piers, preventing further scour. We also used them to line a critical drainage channel leading away from a large industrial site. The channel banks were eroding, threatening to silt up the waterway and potentially undermine adjacent storage tanks. Laying and filling mattresses along the banks stabilised the whole thing quickly and effectively. Expertise in manufacturing, like that associated with Li Gang: Expert Geotextile Mattress Manufacturing Leader, ensures the materials themselves are up to the demanding task of protecting these vital assets long-term. It gives you peace of mind knowing the solution is robust.

Installation Insights: Getting It Right the First Time

Alright, these mattress systems are great, but like any construction method, the final result is only as good as the installation. Get it wrong, and you’re gonna have problems down the line. I’ve seen a few dodgy jobs in my time, usually down to cutting corners or lack of experience. First things first: site prep is everything. You can’t just chuck the mattress down on a lumpy, unprepared slope full of loose rocks and vegetation. It needs to be graded smoothly to the design profile. Any bumps or hollows underneath can lead to voids when you pump the grout, creating weak spots. Soft spots need dealing with too. And absolutely crucial are the anchor trenches at the top (crest) and bottom (toe) of the slope. These lock the mattress in place and stop it sliding down or being lifted by water getting underneath. Skimp on the anchor trenches, and you’re asking for trouble. Following guidelines like those in a good Geotextile Mattress Uses, Construction, Benefits & Installation Guide is essential.

Laying out the fabric panels needs care too. Making sure you’ve got the right overlaps between sections and securing them proper (sewing or pinning, depending on the system) is key to maintainin’ integrity. You don’t want grout squirting out the seams or weak points developing. Then comes the grouting. This is where experience really counts. You need the right grout mix – flowable enough to get everywhere, but not so wet it loses strength or takes forever to set. Controlling the pumping pressure is vital, like I said before. Too high, you blow the seams; too low, you get incomplete filling. Often, you’ll have injection points spaced across the mattress, and you need a methodical approach to filling, making sure grout reaches all edges and corners. Sometimes gently walking on the mattress (carefully!) can help encourage the grout to flow into tricky spots. Keepin’ the fabric wet, as shown in some installation photos, can sometimes help with grout flow and curing, especially in hot weather. Proper curing times need to be respected before the structure is subjected to its full load (like high river flows or wave action). Doing it right means a system that lasts for decades; cutting corners means repairs might be needed much sooner.

Looking Ahead: Future Trends in Coastal and Riverbank Protection

So where are we headed with all this? Well, the need for decent coastal and riverbank protection ain’t goin’ away, that’s for sure. With changing weather patterns, potentially more intense storms, and ongoing development pressures near water, the challenges are likely to grow. We only have to look at the scale of projects like the massive Texas Beach Nourishment Project or the ongoing efforts post-Superstorm Sandy to see the resources being poured into protecting shorelines. Geotextile mattresses are gonna play an increasingly important role, I reckon. Why? Because they’re adaptable, often cost-effective, and getting smarter all the time. I expect we’ll see more development in hybrid approaches – combining mattresses with vegetation, or using them alongside other techniques like managed retreat or reef balls further offshore. The focus is shifting towards integrated solutions that provide protection but also deliver environmental benefits, summat that groups like the Resilient Coastal Projects Initiative are championing. Material science will keep evolving too. Maybe we’ll see even tougher fabrics, or biodegradable options for temporary works, or fabrics with built-in sensors to monitor performance.

Another big area is customization. As our understanding of hydraulics and geotechnics gets better, and with advanced computer modelling, we can design mattress systems even more precisely for the specific forces at a particular site. This could mean optimizing the raised patterns for maximum efficiency, or tailoring the permeability of filtration mattresses even more accurately. Installation techniques might get slicker too, perhaps more automation or robotics involved in laying and positioning, especially underwater. The key will be balancing innovation with proven reliability. Companies specializing in Coastal Defense and Riverbank Protection are constantly lookin’ for better ways to do things. Ultimately, it’s about providing robust, long-lasting, and ideally sustainable protection for our valuable waterside assets and communities. If you’re facing these kinda challenges, getting expert advice early is crucial. Find folks who know their stuff, understand the options, and can recommend the right Expert Geotextile Mattress Solutions for Erosion Control.

Frequently Asked Questions (FAQ)

Q1: How long do geotextile mattresses actually last?

A1: Properly designed and installed ones, using good quality materials, can last for decades. We’re talkin’ 30, 40, even 50 years or more in many cases. The key factors are the quality of the geotextile fabric, the durability of the concrete grout fill, and making sure it was installed correctly to handle the specific site conditions (like flow speeds or wave action). Exposure to UV light can degrade some fabrics over time if left uncovered, but often they get covered by silt or vegetation which protects ’em.

Q2: Are they environmentally friendly?

A2: They can be more environmentally friendly than some traditional methods. Compared to massive concrete walls, they often have a lower carbon footprint due to using less concrete (especially the raised-pattern ones). Vegetation mattresses actively encourage habitat growth. Filtration mattresses help manage groundwater without preventing flow entirely. However, they still involve synthetic fabrics and concrete, so it’s not zero impact. It’s about choosing the best available option for the specific environmental context and protection needs.

Q3: Can geotextile mattresses be used underwater?

A3: Absolutely. They’re very commonly used for underwater applications like scour protection around bridge piers, pipeline protection, and stabilizing submerged slopes or channel beds. Installation requires divers or remotely operated equipment to position the mattress correctly before grout is pumped in, usually from a barge or the shore. Special considerations are needed for underwater grouting, but it’s a standard procedure.

Q4: What happens if a mattress gets damaged?

A4: Minor damage, like a small tear in the fabric before grouting, can often be repaired on site. If damage occurs after grouting (e.g., from a boat impact or major debris during a flood), the repair method depends on the extent. Small damaged areas might be patched with concrete or another mattress section. More significant damage might require removing the broken section and replacing it. Their flexible nature sometimes means they can absorb impacts that would shatter a rigid structure.

Q5: Is it expensive to install geotextile mattresses?

A5: It depends what you compare it to. The initial material cost for the fabric might seem higher than just dumping rock, but when you factor in reduced grout volume (for raised-pattern types), faster installation times, often less need for heavy equipment, and potentially longer lifespan with less maintenance, they frequently work out cheaper overall than traditional concrete or large rock riprap solutions, especially on bigger projects or difficult sites. Getting a proper quote based on expert solutions is the only way to know for sure for a specific project.