Geotextile Fabric Applications and Benefits in Construction

Key Takeaways:

- What it is: Geotextile is a special permeable fabric used in construction and landscaping alongside soil, rock, or earth.

- Main Jobs: It helps with soil stabilization, stops layers mixing (separation), adds strength (reinforcement), helps water pass through cleanly (filtration & drainage), and prevents soil washing away (erosion control).

- Materials: Usually made from strong plastics like polypropylene or polyester.

- Types: Comes in woven (strong, less permeable) and non-woven (more like felt, good for drainage/filtration) forms.

- Uses: Found everywhere from big road projects and retaining walls to managing erosion on slopes and even in smaller garden jobs like under paths.

- Benefits: Makes structures last longer, can cut costs by reducing need for other materials, helps manage water, and protects the environment.

So, you’ve maybe seen this fabric stuff on construction sites? Rolled up, looking kinda industrial? That’s likely geotextile. What is it though, really? Is it just some kinda heavy-duty cloth they throw down? Well, yeah, sorta, but it’s a bit more clever than that. Think of it as a specialist material designed to work with the ground, making things stronger, stopping stuff washing away, or helping water drain properly. Its been around for a while now, and honestly, a lot of the roads you drive on or the garden walls you see probably have some geotextile hidden away, doing its job without you even knowing. It’s one of those unsung heroes in building and landscaping, fixing problems you didn’t even know needed fixing. But what is the actual material? Lets look closer.

What Exactly Is Geotextile Fabric?

So, geotextile, at its heart, it’s a fabric, right? But not like the stuff your clothes are made from. It’s specifically engineered to be put in the ground, or next to soil and rock, and last. The main thing is permeability – it lets water through, sometimes faster, sometimes slower, depending on what type it is and what job its doing. You’ll mostly find them made outta synthetic fibres, things like polypropylene or polyester. Why them? ‘Cause they’re tough. They dont rot when they get wet, they resist chemicals you might find in the soil, and they can handle being stretched and poked without tearing easily. Durability is key, you see. You bury this stuff, you want it to keep working for years, maybe decades.

Now, they generally fall into two big camps: woven and non-woven. Woven geotextiles? They look a bit like that sacking material, but plastic-y. They weave the fibres together in a regular pattern. This makes ’em really strong in terms of tensile strength – they don’t stretch much but can hold things together real well. They’re great for stabilization and reinforcement, like under roads where you need serious strength. Thing is, the gaps between the weaves are quite uniform and sometimes small, so their filtration isn’t always the best for fine soils, and permeability might be lower unless designed otherwise. Non-woven ones, on the other hand, are more like a felt. The fibres are kinda jumbled together, often using heat or needles to bond them. This makes ’em generally more permeable, better filters (the random structure traps particles well), and they stretch more before breaking. You’ll see these used a lot for drainage applications, erosion control under rocks (riprap), and separation. You can even get specific types, like these amazing Transform Terrains with Durable Geotextile Mattresses which are engineered systems for demanding situations. Choosing between woven and non-woven? It really depends on the main job you need it to do – strength or flow? Sometimes you even use both on the same job.

The Big Jobs: Soil Stabilization and Strength

Right, probably one of the biggest uses for geotextiles, ‘specially the woven types, is making the ground more stable. Think about building a road. You got your dirt underneath (the subgrade), then usually a layer of chunky rocks (aggregate base), then the tarmac or concrete on top. Without geotextile, what happens? Over time, especially with heavy traffic pushin’ down, that expensive aggregate layer gets pushed into the softer dirt below. The dirt can also squish up into the aggregate, particularly if its wet. This mixing weakens the whole structure. You lose your nice strong base, and soon you get ruts, potholes, the whole lot. Nightmare.

So, what we do is lay a geotextile fabric between the subgrade and the aggregate layer. This acts as a separator. It stops the layers mixing. Simple as that. The aggregate stays clean and strong, the subgrade stays put. The road lasts way longer, needs less repair. It saves a ton of money in the long run, sometimes reduces the amount of aggregate needed too, which is good for the budget and the environment. It’s not just roads though. Same idea applies under railway tracks (prevents ballast contamination), airport runways, parking lots, any paved area really. Then there’s reinforcement. Geotextiles, particularly woven ones with high tensile strength, actually add strength to the soil itself. Imagine building an embankment or a steep slope. The soil might wanna slump or slide. By layering geotextile within the soil fill, you’re adding something that resists being pulled apart. It holds the soil mass together, letting you build steeper slopes safely, or making retaining walls more effective. We once worked on a tricky slope repair, and using specific Raised-Pattern Geotextile Mattress Systems not only stabilized it but did it way quicker and cheaper than a traditional concrete solution would have. These systems are designed to really grip the soil. It’s clever stuff, properly using the fabric’s strength to make the earth itself stronger.

Keeping Things Dry: Geotextiles for Drainage and Filtration

Water. It’s essential for life, yeah, but in construction, uncontrolled water is usually bad news. It weakens soil, causes hydrostatic pressure behind walls, leads to erosion… a whole heap of problems. This is where non-woven geotextiles often shine. Their main job here is filtration and drainage. Filtration means letting water pass through easily, but stopping soil particles from being carried along with it. Drainage means helping that filtered water move away from where it shouldn’t be. Think about a French drain – basically a ditch filled with gravel around a perforated pipe, designed to collect groundwater. If you just dig a ditch and fill it with gravel, eventually the fine soil particles from the surrounding ground will wash into the gravel, clog it all up, and the drain stops working. Disaster.

But if you line the ditch with a non-woven geotextile before putting the gravel in, the fabric acts as a filter. Water seeps through the fabric from the soil nice and easy, but the fabric’s structure stops the soil particles. Only clean water gets into the gravel and the pipe, so the drain keeps working efficiently for way longer. It’s the same principle behind retaining walls. You get water building up in the soil behind the wall, pushing on it. If you place geotextile against the back of the wall before backfilling, often with a gravel layer too, it lets that water drain through and away, relieving the pressure. You need the right kind of geotextile though. Too tight a weave (or felt), and water flow is restricted. Too open, and fine soil particles get through, potentially clogging things downstream. That’s why you have different grades and types, like specialized Advanced Filtration Geotextile Mattress Systems designed for specific flow rates and soil types. I remember one job, years back, where the wrong spec was used on a sports field drainage system. Looked fine at first, but after the first heavy rain, it just didn’t drain fast enough ’cause the fabric permeability was too low for the sheer volume of water. Had to be redone. Expensive lesson for someone! Get the spec right, it works brill.

Stopping Washouts: Erosion Control with Geotextiles

Erosion. Wind and water constantly trying to shift soil and sand where you don’t want it. Riverbanks getting undercut, coastal areas washing away, slopes losing topsoil after heavy rain. It’s a massive problem, costing loads in damage and repair. Geotextiles are a key weapon in fighting it. The basic idea is protection. You cover the vulnerable soil surface with the geotextile fabric. This does a few things. First, it shields the soil directly from the impact of raindrops or the force of flowing water. Second, it helps hold the soil particles together, making it harder for them to be picked up and carried away.

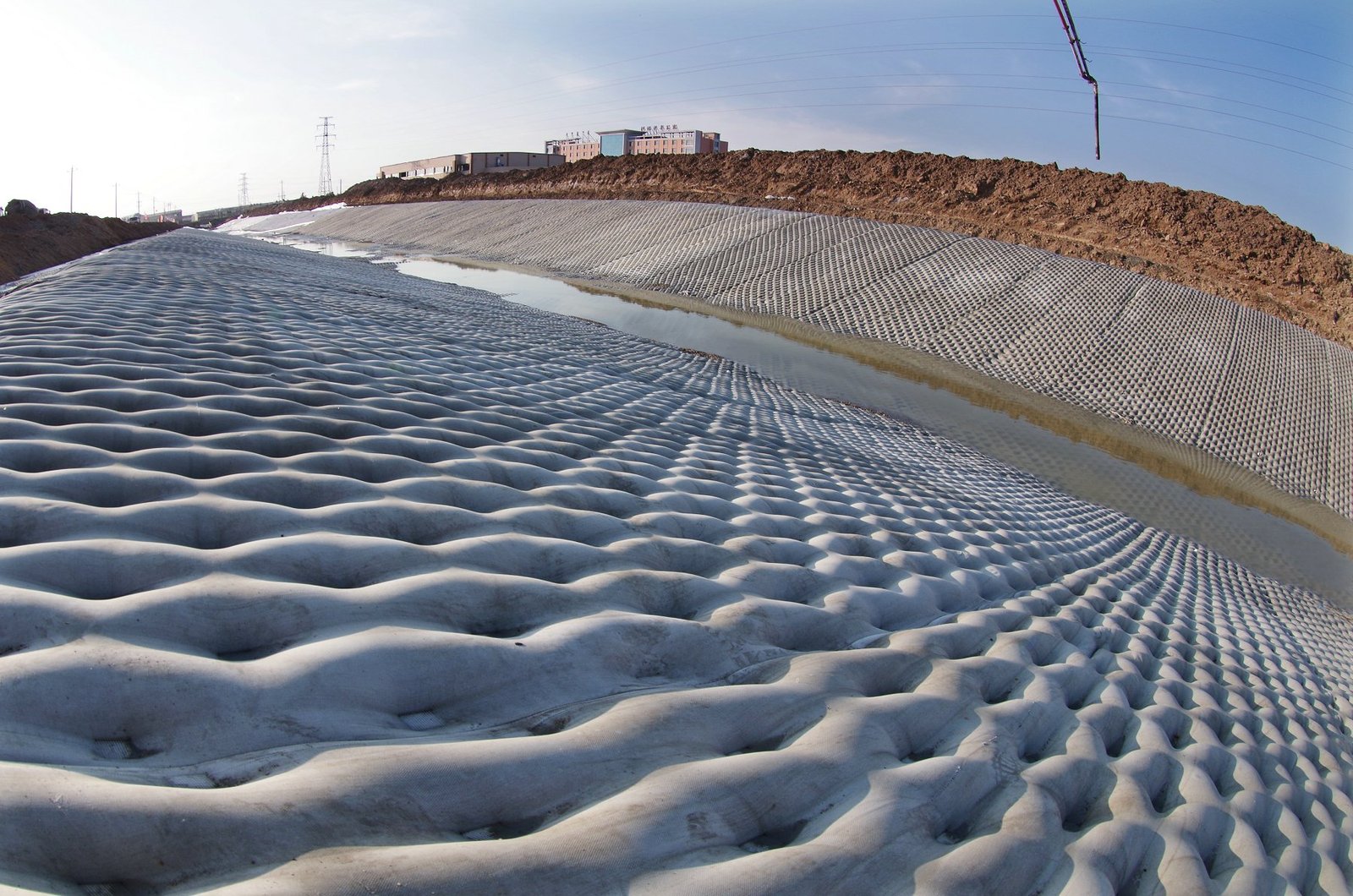

You see this used loads on riverbanks and coastlines. Often, they’ll put down a layer of geotextile, then cover it with heavy rocks (riprap) or concrete blocks. The geotextile stops the underlying soil being washed out through the gaps in the rocks or blocks. Without it, the water would just scour away the soil underneath, causing the whole protective layer to slump and fail. It makes the whole structure way more stable and long-lasting. On slopes, you might use geotextiles pinned to the surface, sometimes special types designed to allow vegetation to grow through them. The fabric provides immediate protection while the plants establish their roots, which then add long-term stability. For really demanding situations, like canal linings or steep spillways, purpose-built systems like Geotextile Mattresses are fantastic. These are often double-layered fabrics stitched together in compartments, which are then filled with concrete or grout after being laid in place. They conform to the ground shape but create a super tough, flexible, erosion-resistant surface. Checking out some Proven Geotextile Mattress Projects for Water Infrastructure shows just how effective these can be. Getting the right system is important, and sometimes you need Expert Geotextile Mattress Solutions for Erosion Control advice to choose the best approach. There are definite Advantages and Applications of Geotextiles Mattresses in Erosion Control worth knowing about for bigger jobs.

Landscaping and Smaller Projects: Not Just for Big Builds

You might think this geotextile stuff is just for massive civil engineering projects, roads, dams, that kinda thing. And yeah, it’s crucial there. But it’s dead useful for smaller jobs too, the sort of thing landscapers deal with all the time, or even keen DIYers in their own gardens. One common use? Underneath gravel paths or driveways, or patios laid on a gravel base. Same principle as the roads, just smaller scale. You put the geotextile down first, then your gravel or stone mix. It stops the gravel disappearing into the soil below, keeps your path surface more stable, and helps prevent weeds pokin’ through from underneath (though it’s not always a perfect weed barrier, determined weeds can sometimes find a way, but it definitely helps!).

It makes the path last longer and look neater. Less sinking, less topping up the gravel every year. Another place is lining planters or raised beds, ‘specially wooden ones. It helps keep the soil contained, stops it washing out through the drainage holes or gaps in the wood, but still lets excess water drain away. Using it in things like green roofs or living walls is becoming more popular too, for separation and filtration layers. And think about building a small garden pond with a liner. Putting a layer of protective geotextile (usually a thicker, cushiony non-woven) under the waterproof liner helps protect it from sharp stones or roots in the ground that could puncture it. It extends the life of your fancy pond liner. You can usually buy geotextile in smaller rolls from builder’s merchants or landscaping suppliers, so it’s pretty accessible. The Geotextile Mattress Uses, Benefits & Installation Guide might give some more ideas, even if it focuses on the mattress type, the principles often apply. It’s just about understanding those core functions – separation, filtration, protection – and seeing where they can solve a smaller problem in the garden or landscape.

Environmental Perks and Future Stuff

Beyond just making things stronger or last longer, using geotextiles often brings some nice environmental benefits too, which is somethin’ were all more conscious of these days, right? For starters, by improving soil stability and acting as a separator under roads and railways, you often need less quarried aggregate material. Digging up stone and transporting it uses a lot of energy and impacts landscapes, so reducing the amount needed is a definite plus. Also, in erosion control, geotextiles provide immediate protection, helping prevent valuable topsoil being washed away into rivers and streams. Soil loss is a big environmental issue, affecting water quality and agricultural land. Keeping soil where it should be is important.

Then there’s water management. Geotextiles used in drainage systems help manage stormwater runoff more effectively, preventing localized flooding and filtering pollutants before water enters waterways. Some advanced systems are even designed specifically to work with nature. Take these Advanced Vegetation Geotextile Mattress Systems for Slope Stability. They’re designed not just to hold the slope initially, but to actively encourage plants to grow through them. The fabric provides the immediate erosion control and stability, and then as the plants establish, their roots create a natural, long-term reinforcement. It’s a great blend of engineered protection and natural processes. The future likely holds more innovations like this – smarter fabrics, maybe biodegradable ones for temporary applications, materials with embedded sensors to monitor soil conditions… who knows? But the core idea of using engineered fabrics to improve how we interact with the ground is here to stay. Ensuring these systems are manufactured and installed correctly is vital for them to perform properly, which is where expert knowledge, like that of manufacturing leaders such as Li Gang: Expert Geotextile Mattress Manufacturing Leader, becomes really crucial, especially when dealing with Specialized Geotextile Protection for Critical Infrastructure. Proper installation isn’t just about making it work; it’s about making it work for its full design life, maximizing those benefits.

Summing Up: Why Geotextiles are Kinda Important

So, after all that, what’s the big takeaway? Geotextiles might look simple – just rolls of fabric – but they’re actually pretty sophisticated bits of engineering designed to solve real-world problems when building on, or with, soil and rock. They aren’t just one thing; they perform several key jobs that are fundamental in construction and landscaping:

- Separation: Keeping different layers (like soil and gravel) from mixing.

- Reinforcement: Adding tensile strength to soil, making it stronger.

- Filtration: Letting water pass through but keeping soil particles behind.

- Drainage: Helping water move through the ground in a controlled way.

- Protection: Shielding soil surfaces from erosion caused by water or wind.

The uses are incredibly varied. We’ve seen how they’re essential under roads, railways, and runways, how they help build stable embankments and retaining walls, how they control erosion along rivers and coastlines, and how they improve drainage systems. But they also pop up in landfill engineering, pond construction, and even smaller garden projects like paths and planters. Systems like Geotextile Mattresses show how specialized these products can become for specific, demanding applications, with many Proven Geotextile Mattress Projects for Water Infrastructure demonstrating their success. They often save money by reducing the need for other materials or extending the life of a project, meaning fewer repairs down the line. They contribute to more stable, reliable, and sometimes even greener construction practices. So next time you see a construction site, have a look – you might just spot a roll of geotextile waiting to be laid, ready to quietly do its important job underground. They’re definitely materials worth knowing about if you’re involved in any kind of earthworks.

Frequently Asked Questions (FAQs)

Q1: What’s the main difference between woven and non-woven geotextiles?

A1: Woven geotextiles are made by weaving fibres together, making them very strong with high tensile strength but often less permeable – good for reinforcement and stabilization. Non-woven geotextiles are more like felt, with randomly arranged fibres, making them generally better for filtration, drainage, and separation tasks as they let water through more easily while holding back soil.

Q2: Can I use any geotextile for any job?

A2: No, definitely not! Using the wrong type can cause problems. For example, using a low-permeability woven fabric where you need good drainage wont work well. You need to choose based on the primary function required (strength, filtration, separation etc.) and the site conditions (soil type, water flow). Getting the specification right is real important.

Q3: How long does geotextile last?

A3: When installed correctly and made from durable synthetic materials like polypropylene or polyester, geotextiles can last for many decades, even over 100 years in some applications. They are designed to resist rot, chemicals, and UV degradation (though they should usually be covered from direct sunlight long-term).

Q4: Is geotextile fabric waterproof?

A4: No, geotextiles are designed to be permeable, meaning they let water pass through. They are not waterproof barriers like pond liners (geomembranes). Their job is usually related to controlling water flow or soil interaction, not stopping water completely.

Q5: Can geotextile stop weeds in my garden?

A5: It can help, yes. Laid under gravel paths or mulch, it acts as a physical barrier making it harder for weeds to grow up from the soil below. However, some tough weeds might still find a way through, especially at seams or edges, and weeds can still grow in the gravel or mulch on top of the fabric from blown-in seeds. So, it helps suppress weeds, but isn’t always a 100% permanent solution on its own.