Challenges of Geotextile Mattresses in Marine Erosion Control

Key Takeaways

- Harsh Conditions: Marine environments mean constant battles with waves, currents, saltwater, and UV light, which really test the mattress materials.

- Tricky Installation: Getting these big, heavy things placed right underwater is tough; needs special gear, skilled divers, and good weather windows. Visibility can be rubbish too.

- Biofouling Happens: Sea critters like to grow on stuff, and geotextile mattresses are no exception. This can clog them up or even damage the fabric.

- Scour is a Risk: Water moving around the edges can wash away the seabed underneath, leaving the mattress unsupported. Proper anchoring and edge design are critical.

- Material Choice Matters: You gotta pick the right type of geotextile fabric that can handle saltwater, sun, and getting bashed about for years. Not all materials are created equal for this job.

- Solutions Exist: Despite the challenges, using robust designs, the right materials, careful installation, and sometimes combining them with other methods means they often work really well for Expert Geotextile Mattress Solutions for Erosion Control.

Introduction: What’s the Deal with Geotextile Mattresses by the Sea?

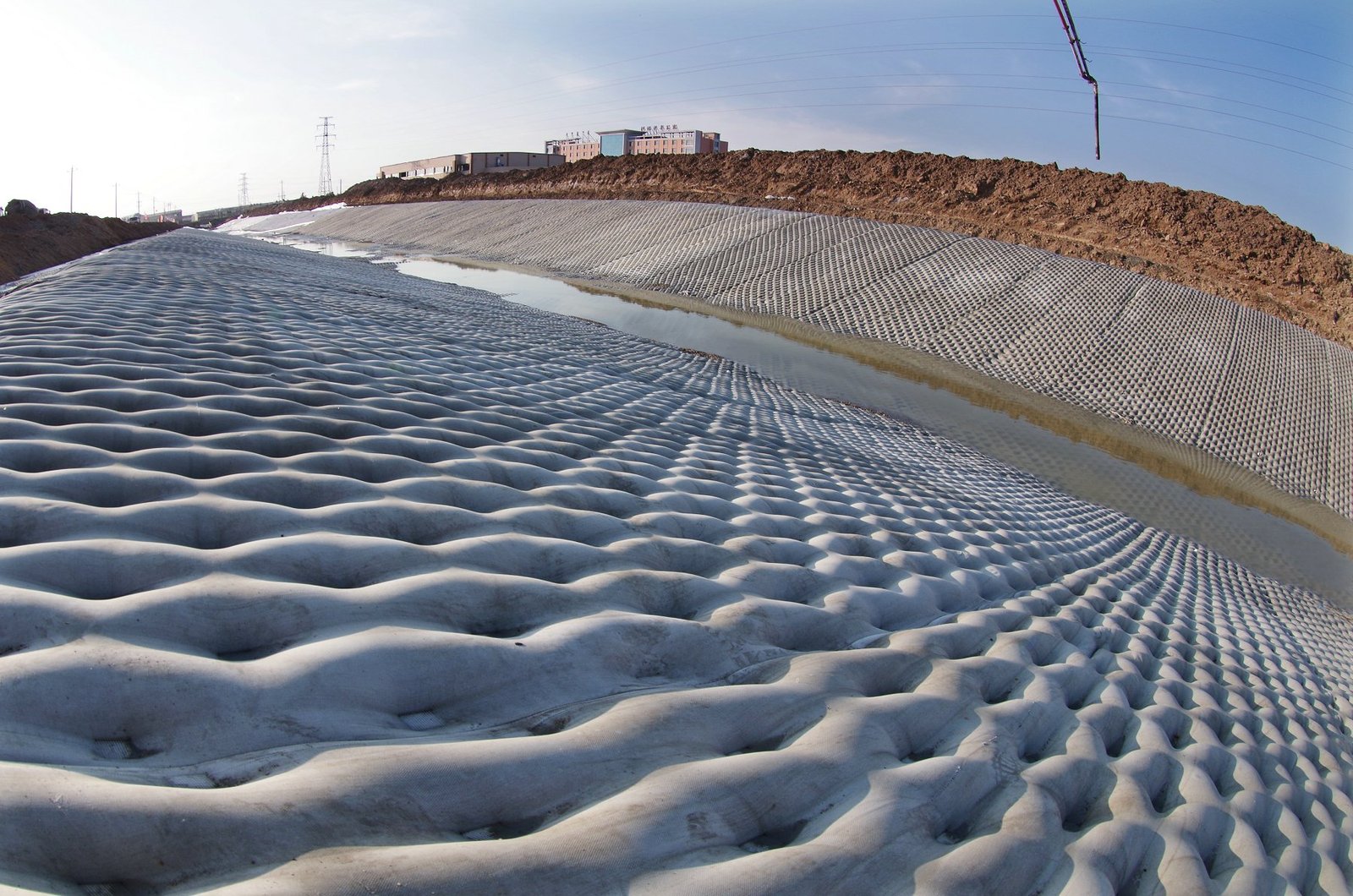

So, you’ve heard about Transform Terrains with Durable Geotextile Mattresses. They’re basically big fabric envelopes, often made from tough synthetic stuff, that you fill up, usually with concrete or grout, sometimes sand or local material. On land, or in rivers, they’re great for stopping soil washing away, supporting banks, lining channels, that sorta thing. People use em for Effective Slope Stabilization and Erosion Control Guide and even things like Advanced Vegetation Geotextile Mattress Systems for Slope Stability where you want plants to grow through them eventually. Sounds simple enough, right?

But take these things offshore, into the sea or salty estuaries, and it’s a whole different ball game. The ocean dont play nice. Suddenly you’re dealing with forces and conditions that just dont exist, or aren’t as bad, inland. We’re talking constant movement from waves and tides, corrosive saltwater trying to eat everything, sunlight beating down, and a load of sea creatures that might decide your expensive mattress looks like a good home or even a snack. The basic idea is the same – stop erosion, protect structures like pipelines or bridge foundations, maybe build up artificial reefs – but getting them to work reliably in the marine zone brings a bunch of headaches. It’s not just about plopping them down; the whole process from design to installation Needs careful thought about these specific marine challenges. Knowing the Advantages and Applications of Geotextile Mattresses in Erosion Control is one thing, but adapting them successfully for the coast is another level. We gotta look at what makes it so tricky.

Harsh Physical Conditions: Waves, Currents, Salt, and Sun

Right, first big hurdle: the physical environment itself. Oceans are just relentlessly dynamic places. You got waves constantly pounding the shore or any structure you put out there. Even moderate waves exert huge forces, lifting, pushing, pulling. If a mattress isn’t heavy enough, or anchored down proper, it can get shifted about, maybe even ripped apart over time. Think about a storm surge – the forces are incredible. Then there’s currents, tidal currents or longshore drift. These steady flows of water can try to undermine the mattress, washing sediment out from underneath it (we’ll talk more about scour later), and they also make installation a real pain. Trying to place a flexible mattress accurately when the water’s constantly trying to push it sideways? Not easy.

And its not just the moving water. Saltwater is notoriously corrosive. While the geotextile fabrics themselves are usually polymers (plastics, basically) which resist corrosion pretty well compared to metal, the filling material, often concrete or grout, can be affected. More importantly, any metal components used for anchoring or connecting mattresses can degrade fast if they’re not the right spec, like stainless steel or specialized alloys. Even the polymers aren’t totally immune long-term. Sunlight, specifically the UV radiation part, breaks down plastics over time. If parts of the mattress are exposed above the waterline, or in very clear shallow water, UV degradation can make the fabric brittle and weak over years. We’ve seen projects where the top layer looked fine but underneath, where it got constant sun during low tides, the material was starting to go. Choosing UV-stabilized materials is essential, but even then, nothing lasts forever out there. It demands really durable geotextile mattresses designed specifically for these impacts. External resources like those discussing Innovative Composite Marine Structures often highlight materials designed to combat these exact issues. The constant wet/dry cycles in tidal zones can also stress materials differently than being permanently submerged or permanently dry.

Installation Difficulties: Getting Them in Place Underwater

Okay, so designing a mattress that can survive the sea is one thing. Actually getting it installed correctly is a whole other challenge. These things can be massive, covering large areas of seabed or slope, and once filled, they’re incredibly heavy. You’re not just chucking them off the side of a boat. It typically involves specialized barges, cranes, pumping equipment for the grout/concrete fill, and often a team of commercial divers. Working underwater is inherently difficult and expensive. Visibility might be terrible, especially in murky coastal waters or estuaries. Divers are working in currents, sometimes significant ones, trying to guide these massive fabric sheets into the exact right position, ensuring they overlap correctly if multiple mattresses are needed, and connecting them securely.

Weather is a huge factor too. You need relatively calm seas to carry out installation safely and accurately. Around here, finding a long enough weather window, especially in winter, can be a nightmare, leading to project delays and increased costs. Imagine trying to precisely pump grout into a mattress form underwater when a Force 5 wind kicks up waves – it’s just not happening. The logistics are complex. You need to get the empty mattress fabric to the site, deploy it (often using spreader beams to keep it flat), position it, maybe pin it temporarily, then connect the filling hoses and pump potentially hundreds of cubic meters of fill material, all while monitoring it doesn’t shift or get damaged. The whole process is detailed in resources like the Geotextile Mattress Uses, Construction, Benefits & Installation Guide, but doing it underwater magnifies every single difficulty. Sometimes, pre-filling sections onshore and lifting them into place is an option, but that requires seriously heavy lifting gear and careful handling to avoid damaging the mattress before it even touches the water. Its just alot more complicated than laying one out on a riverbank.

Interaction with Marine Life: Biofouling and Critter Damage

The sea is full of life, and anything you put in it quickly becomes real estate. This is called biofouling – the accumulation of microorganisms, plants, algae, and animals on submerged structures. Geotextile mattresses are prime candidates. Initially, a slime layer (biofilm) forms, then algae, barnacles, mussels, seaweed, sponges, all sorts can start growing on the fabric surface. Now, sometimes this isn’t a huge problem, might even be seen as positive as it creates habitat. But it can cause issues. If the mattress is designed to be permeable, maybe allowing water pressure to release or acting as part of a filter system like in Advanced Filtration Geotextile Mattress Systems, a thick layer of marine growth can clog up the pores, reducing its effectiveness. I’ve seen filter points completely blocked by barnacle growth on some older projects.

The weight of the biofouling itself can also add considerable load to the mattress, especially if large seaweeds take hold in high-current areas. Then there’s direct damage. Some critters actively burrow or bore. Things like piddocks (a type of boring clam) can potentially drill into grout-filled mattresses over time. Crabs and lobsters might find shelter in gaps or under edges, and their activity could potentially disturb the fabric or the sediment around it. On a project protecting a pipeline crossing, we had issues with crabs digging under the mattress edges, which needed addressing with extra toe protection. Even fish grazing on algae growing on the fabric could theoretically cause abrasive wear over very long periods. While catastrophic damage from animals is maybe less common than installation or scour problems, it’s still a factor to consider in the long-term performance and durability, especially for softer fill types or exposed fabric sections. It’s another layer of complexity you just dont get in a freshwater river.

Substrate Interaction and Scour: The Undermining Threat

This one’s a biggie, maybe the most common failure mode if not designed right. Scour. It’s when moving water erodes the seabed material – sand, silt, whatever – from around the edges or even underneath a structure. Geotextile mattresses, while designed to prevent erosion on the area they cover, can actually cause scour right next to them if you’re not careful. Think about it: water flowing over a smooth mattress might speed up slightly, or water hitting the edge might create turbulence. This concentrated energy can dig away at the unprotected seabed at the mattress toe or along its sides. If enough material washes out, the edge of the mattress can be left unsupported, slump down, or the current can get underneath it, lifting it up. Once that starts, it can unravel pretty quickly.

So, designing the edges and transitions is absolutely critical. You often need a ‘scour apron’ – an extra width of mattress or a layer of smaller rock (riprap) placed along the edges to protect the adjacent seabed. Sometimes digging the mattress toe into the existing seabed (keying it in) is necessary. Anchoring systems also play a part here, making sure the mattress stays put even if some minor scour occurs nearby. The type of seabed makes a huge difference too. Installing on shifting sands is much trickier regarding scour than on cohesive clay or rock. We had a job on a sandy estuary entrance where modelling predicted significant scour potential, so we ended up using Raised-Pattern Geotextile Mattress Systems Cut Costs 40% which have a rougher surface to dissipate energy, combined with a substantial rock armour toe. Understanding the local hydrodynamics (how the water moves) and sediment transport is key before you even start choosing the mattress type. Proper site investigation is non-negotiable for marine jobs involving these systems, way more so than for many land-based applications. You need to predict where scour might happen and design to prevent it right from the start. Ignoring this is asking for trouble.

Material Selection and Durability: Choosing the Right Stuff

Not all geotextiles are born equal, ‘specially not when you throw ’em in the ocean. Choosing the right material is fundamental for long-term success. You’re basically looking for a fabric that can handle a nasty combination of things:

- Mechanical Stress: Needs to be strong enough to hold the fill material without bursting during installation (hydraulic pressure from pumping grout can be immense) and tough enough to resist abrasion from waves, currents, moving sediment, maybe even boat anchors or debris. Puncture resistance is important too.

- UV Resistance: As mentioned before, if any part is exposed to sunlight, it needs excellent UV stabilization to prevent degradation.

- Chemical Resistance: Must be inert to saltwater and any potential pollutants in the water. Most common geotextile polymers (polypropylene, polyester) are pretty good with salt, but water chemistry can vary.

- Biological Resistance: Needs to resist rotting or degradation from microbes, and ideally be unattractive to those critters that might try to eat or bore through it.

The main choices are usually between woven and non-woven fabrics, and different polymer types. Wovens are generally stronger and less likely to stretch, which can be good for holding shape. Non-wovens are often better for filtration and are more flexible, conforming better to uneven seabeds. Sometimes composites are used. The specific polymer matters too – polyester generally has better UV resistance and creep resistance (less likely to stretch slowly under constant load) than polypropylene, but might be more susceptible to hydrolysis (breaking down with water) in certain conditions, tho modern formulations are much better. High-density polyethylene (HDPE) is another option, known for excellent chemical resistance. Resources like the Non-Woven Geotextile Market Research Report show the trends in material usage.

Beyond the fabric, the fill material choice (concrete mix design, sand specification) and any anchoring components (pins, cables, connectors) need similar scrutiny for marine durability. It’s about the whole system working together for decades, hopefully. Getting expert advice on material specification is crucial for Specialized Geotextile Protection for Critical Infrastructure in marine zones. You don’t want to find out ten years down the line that you picked a fabric that looked okay on the spec sheet but couldn’t handle the real-world marine environment; thats an expensive mistake. Proper specification is one of the core Advantages of Geotextile Mattresses in Erosion Control when done right.

Solutions and Best Practices: Making Marine Mattresses Work

So yeah, its tricky, but it’s absolutely doable. Engineers have been using geotextile mattresses and similar systems like those discussed in “Polymeric Marine Mattresses” successfully in coastal and offshore projects for years. The key is acknowledging these challenges upfront and designing specifically to overcome them. What does that look like in practice?

First, robust design based on site conditions. This means detailed surveys – bathymetry (seabed shape), geotechnical investigations (what the seabed is made of), and hydrodynamic studies (waves, currents). You cant guess this stuff. The design needs to calculate the required mattress thickness, weight, and anchoring to resist the forces it’ll encounter, with a decent safety factor built in. Edge protection against scour is usually non-negotiable. Sometimes, innovative designs like the Raised-Pattern Geotextile Mattress Systems can help by increasing stability and reducing uplift forces.

Second, careful material selection. As discussed, choosing high-grade, durable polymers with proven resistance to UV, saltwater, and biological attack is critical. Getting advice from experienced suppliers or specialists like Li Gang: Expert Geotextile Mattress Manufacturing Leader can be invaluable. The fill material needs careful specification too, ensuring its density and strength meet the design requirements.

Third, meticulous installation planning and execution. This means using experienced contractors with the right equipment (barges, pumps, dive teams). Quality control during filling is vital – ensuring no voids, achieving the correct thickness, and making sure overlaps and connections are secure. Real-time monitoring, maybe using sonar or ROVs (Remotely Operated Vehicles) alongside divers, can help ensure correct placement. Sometimes combining geotextiles with other methods, like rock armour or specialized Synthetic Marine Solutions, provides the best overall result.

Fourth, long-term monitoring. Periodic inspections, especially after major storms, are a good idea to check for any signs of damage, settlement, or scour that might need remedial action. Looking at Proven Geotextile Mattress Projects for Water Infrastructure often shows that success comes from thoroughness at every stage. It’s not just about the mattress itself, but the whole approach from initial study to post-installation checks.

Conclusion: Tough Job, But Often the Right Tool

Using geotextile mattresses in the sea defintely throws up more curveballs than using them on land. The constant attack from waves, currents, saltwater corruption, sunlight, and even little sea critters means you absolutely have to do your homework. Installation is complex, needing specialized gear and skills to get it right underwater. And the risk of scour undermining the whole thing is always lurking if the edges aren’t designed properly.

But despite all that, they remain a really valuable tool for coastal and marine engineers. When you properly analyse the site conditions, select the right tough materials, design robustly (especially those edges!), and install carefully, they provide excellent, long-lasting protection against erosion for shorelines, structures, and pipelines. Compared to just dumping tons of rock, they can sometimes be more cost-effective, use less quarried material, and conform better to the seabed. We’ve seen countless successful Proven Geotextile Mattress Projects for Water Infrastructure that demonstrate their effectiveness. The trick isn’t if they work in marine environments, but how to make them work reliably given all the challenges. It demands expertise, caution, and a healthy respect for the power of the ocean, seeking out Expert Geotextile Mattress Solutions for Erosion Control when needed. They defintely have their place in protecting our coasts.

Frequently Asked Questions (FAQs)

Q1: What’s the biggest challenge when using geotextile mattresses in the sea?

A: It’s tough to pick just one! But scour (water washing away the seabed around the edges) and the difficulty of accurate underwater installation in potentially rough conditions are probably the most common major headaches engineers face. Harsh physical forces (waves/currents) are a close second.

Q2: Can marine growth (biofouling) damage the mattress?

A: Usually, the growth itself (like algae or barnacles) doesn’t directly damage strong geotextile fabrics or concrete fill. However, it can clog filter points if permeability is important, and some boring organisms could potentially cause damage over long timescales. Its main impact is often on performance rather than structural integrity, but needs considering.

Q3: How deep underwater can geotextile mattresses be installed?

A: The depth limit depends more on the practicalities and cost of installation (diver limits, equipment reach, pumping pressure) than the mattress itself. They’ve been installed in relatively deep water for pipeline protection (tens of meters), but installation gets significantly more complex and expensive the deeper you go. Shallow water coastal protection is more common.

Q4: Are geotextile mattresses bad for the marine environment?

A: Generally, they’re considered less intrusive than some traditional methods like massive rock dumps. They use manufactured materials, but once installed and potentially covered with some natural sediment or colonized by marine life, they can provide stable habitat. Using inert fill materials is important. Like any construction, installation causes temporary disturbance. Overall impact depends on the specific project and how well it’s designed.

Q5: How long do geotextile mattresses last in saltwater?

A: A long time, if designed and installed correctly using the right materials! High-quality polymer geotextiles are very resistant to saltwater and biological decay. Design life often targets several decades (e.g., 50+ years), similar to other coastal defense structures. UV exposure above water can be a limiting factor if not properly accounted for in material selection. Look at Specialized Geotextile Protection for Critical Infrastructure for examples of long-term applications.