Affordable Geotextile Fabric Options and Pricing Analysis

Right then, let’s get to it. Figuring out the cost of geotextile fabric can feel like a bit of a puzzle, but it ain’t rocket science once ya break it down.

Key Takeaways: What You Need to Know ‘Bout Geotextile Costs

- Material Matters Most: The raw stuff, usually polypropylene or polyester, is a big driver of price. Their market prices go up and down, affecting the final cost.

- How It’s Made Counts: Woven geotextiles (strong, for stabilization) and non-woven ones (good for drainage and filtering) have different manufacturing processes, and that changes the price tag. Special types like geotextile mattresses can have their own cost factors.

- Stronger Can Be Pricier: Generally, the thicker, heavier, and more tear-resistant the fabric, the more it’s gonna cost ya. But, this often means it lasts longer, so it’s a trade-off.

- Project Needs Dictate: A small garden path won’t need the same heavy-duty (and expensive) geotextile as a massive retaining wall or a critical infrastructure protection project.

- Buyin’ in Bulk Saves Cash: Like with most things, ordering larger quantities usually gets you a better per-unit price.

- Don’t Forget Extras: Shipping, and any special features like UV protection or specific colors, can add to the bill.

Alright, let’s dig in a bit deeper.

Just What is This Geotextile Fabric Stuff Anyway?

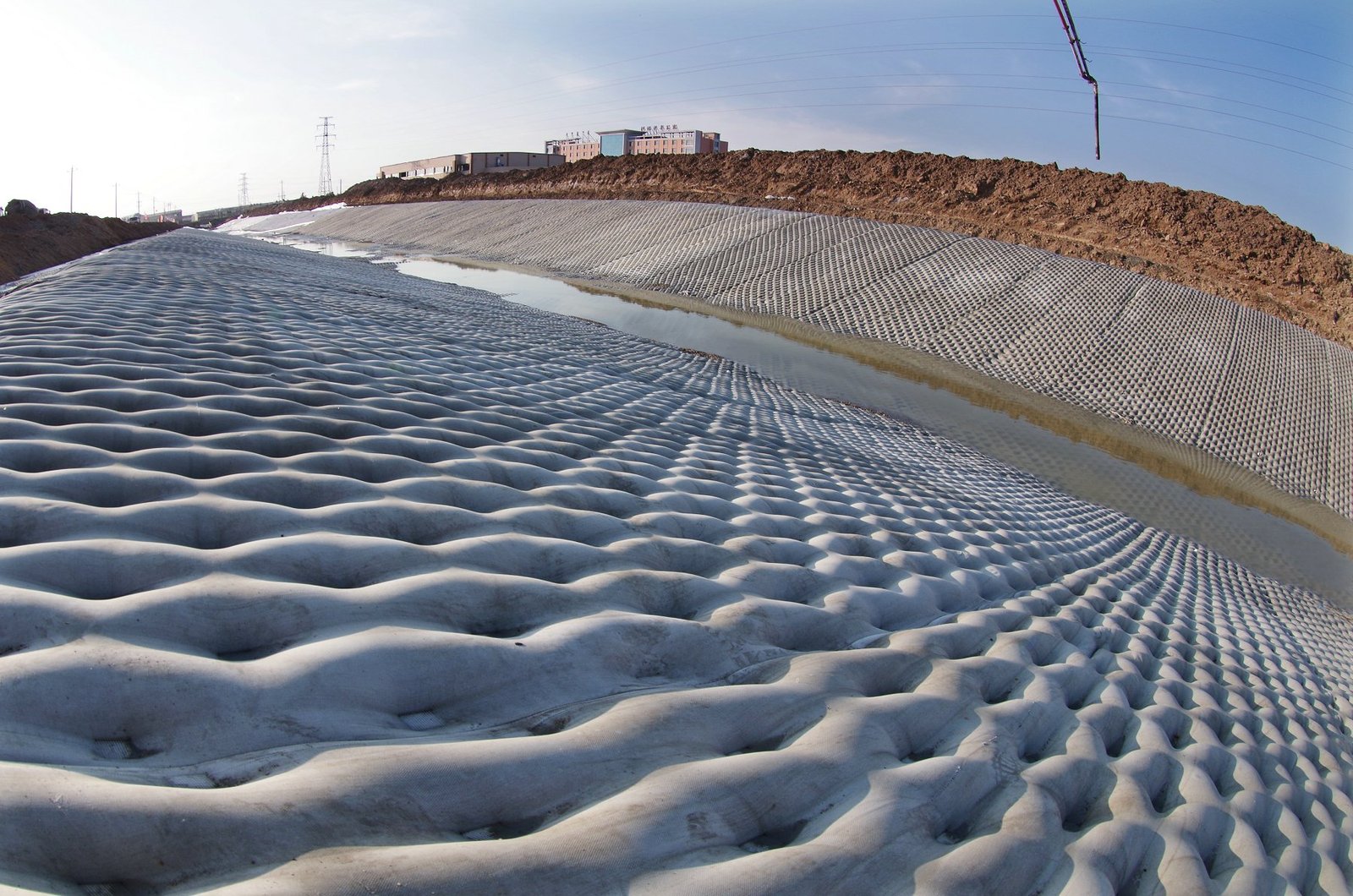

So, you’ve heard the term “geotextile fabric” thrown around, especially if you’re lookin’ at any kind of construction, landscaping, or erosion control project. But what is it, really? Simply put, it’s a special type of fabric, a textile, that’s used in contact with soil – that’s where the “geo” part comes from. Think of it like a super-tough, engineered cloth that helps make the ground behave itself. Its main jobs are usually things like separation (keepin’ different soil layers from mixin’), filtration (lettin’ water pass through but holdin’ back soil particles), reinforcement (makin’ soil stronger), drainage (helpin’ water get away), and protection (guardin’ stuff like pond liners from gettin’ poked). I remember one job we did on a tricky slope; without a good geotextile, every heavy rain would’ve been a disaster, washin’ everything away. We used a specific vegetation geotextile mattress, and it held everything together beautifully, even lettin’ plants grow through to lock it in further.

Understandin’ the cost is super important ’cause it can be a fair chunk of your project budget. You don’t wanna skimp and get somethin’ that fails, ’cause then you’re payin’ twice – once for the cheap stuff and again for the good stuff plus the repairs! But you also don’t wanna overspend on features you just don’t need. It’s all about findin’ that sweet spot. The price ain’t just a number; it reflects the technology, the materials, and the performance you’re gettin’. Some folks just see a roll of fabric, but I see years of research and development that helps keep our roads from sinkin’ and our riverbanks from erodin’. It’s pretty clever stuff, actually, and knowin’ what goes into it helps justify the spend when you need the reliable performance.

The Nitty-Gritty: What Makes Geotextile Prices Go Up or Down?

Alright, so why does one roll of geotextile cost X amount and another, seemingly similar roll, cost Y? There’s a whole bunch of things that play into it, kinda like bakin’ a cake – the ingredients and how you mix ’em change the final product, and the price. First up, the raw materials themselves. Most geotextiles are made from polymers like polypropylene or polyester. These are petroleum-based products, so guess what? When oil prices go for a wander, the cost of these polymers often follows. A few years back, when oil spiked, we saw a noticeable bump in geotextile prices almost immediately. It’s somethin’ you gotta keep an eye on if you’re plannin’ a big purchase. This can really affect the overall budget for proven geotextile mattress projects for water infrastructure, where large quantities are often needed.

Then there’s how it’s actually made – the manufacturing process. You’ve basically got two main camps: woven and non-woven. Woven geotextiles are made by, well, weavin’ strands of material together, kinda like a super-strong basket. This usually gives ’em high tensile strength, makin’ ’em good for stabilization and reinforcement. Non-wovens are more like a felt; the fibers are either needle-punched together or thermally bonded. These are often better for filtration and separation. The complexity and energy used in these processes ain’t the same, so that translates to cost differences. Some specialized non-wovens, particularly those for demanding advanced filtration geotextile mattress systems, might involve more intricate manufacturing steps.

The thickness and weight of the fabric, often measured in ounces per square yard or grams per square meter, is another biggie. More material generally means more cost, simple as that. A heavy-duty, thick fabric designed to withstand serious punishment is naturally gonna be pricier than a lighter-weight option for less demanding jobs. Think about it – a robust fabric for under a highway needs to be way tougher than one for a simple garden weed barrier. Special treatments also add to the cost. Need it to be UV resistant ’cause it’s gonna see a lotta sun? That’s an additive or a coating, and that costs money. Some geotextiles come with specific coatings to enhance chemical resistance or even encourage vegetation growth. And of course, how much you’re buyin’ plays a role. A single, small roll for a DIY job will have a higher per-unit cost than if you’re buyin’ multiple truckloads for a massive civil engineering project. Suppliers often give discounts for bulk orders, so it pays to plan ahead and consolidate if you can. Even the brand or supplier can influence price; some have a reputation for premium quality and service, which might be reflected in their pricing. For folks lookin’ to transform terrains with durable geotextile mattresses, considerin’ these factors is key to effective budgeting.

Woven, Non-Woven, or Something Fancy? Types and Their Price Tags

When you’re lookin’ at geotextiles, you’ll quickly see there’s more than just one type. The big division, as I mentioned, is between woven and non-woven, and this difference really impacts the price tag and what the fabric is good for. Woven geotextiles, they’re like the strongmen of the fabric world. They’re made by interweaving polypropylene or polyester yarns, almost like denim but way, way tougher. This gives ’em super high tensile strength and low elongation – meaning they don’t stretch much. Because of this strength, they’re often the go-to for soil stabilization, reinforcement under roads or retaining walls, and anywhere you need to spread a load out. Naturally, this robust construction and strength can mean they’re often a bit pricier per square yard compared to some non-wovens. I’ve seen ’em used under massive earthworks where anything less just wouldn’t cut it.

On the other side, you got non-woven geotextiles. These are more like a tough felt. The fibers ain’t woven but are either tangled together mechanically (that’s called needle-punching) or melted together (thermal bonding). The result is a fabric that’s generally thicker and more permeable than wovens. Their big strengths are in filtration – letting water through while keeping soil particles out – and separation, preventing different layers of soil or aggregate from mixing. Think French drains, erosion control under riprap, or as a cushion for pond liners. Because the manufacturing can be a bit less intensive for some basic non-wovens, their price point can sometimes be lower, but it really varies. A high-performance non-woven designed for specific advanced filtration geotextile mattress systems with precise pore sizes will cost more than a general-purpose non-woven.

Then you get into the more specialized stuff, like vegetation geotextile mattress systems for slope stability. These are often composite products, maybe combining a geotextile with some kind of erosion control blanket or features that help plants take root. They’re designed for specific, tricky situations like steep slopes where you need both immediate erosion protection and long-term vegetative cover. These are gonna have a cost structure that reflects their complexity and the multiple benefits they offer. And sometimes, you find innovations that actually aim to bring costs down while maintaining performance. For instance, some raised-pattern geotextile mattress systems cut costs 40% by optimizing material use or installation efficiency, offering better value in the long run. So, it’s not just woven vs. non-woven; the specific application and any special design features really play a massive role in the final price. It’s always a good idea to check out a comprehensive geotextile mattress uses, benefits & installation guide to match the right type to your project and budget.

From Factory to Field: Unpacking the Cost Layers

Getting that roll of geotextile fabric from a pile of raw polymer pellets to your job site involves a surprising number of steps, and each one adds a little somethin’ to the final cost you pay. It’s not just the fabric itself; it’s a whole chain of events and processes. The journey starts with those raw materials, usually polypropylene or polyester resins. As we touched on, these are derived from petroleum or natural gas, so their base cost fluctuates with the global energy markets. A sudden hike in crude oil prices, and you can bet the manufacturers are feelin’ it, and that pinch eventually makes its way to the buyer. It’s why companies like those led by experts such as Li Gang: Expert Geotextile Mattress Manufacturing Leader Siga Company, keep a close eye on these commodity markets. They need to manage their input costs to stay competitive but also to ensure they’re not compromising on the quality of the polymers they use.

Once the raw material is sourced, it’s gotta be turned into fabric. This manufacturing process is a big cost component. Whether it’s extruding fibers, weaving them on giant looms, or needle-punching and thermally bonding non-wovens, it all requires specialized machinery, energy to run that machinery, and skilled labor to oversee it all. More complex fabrics, like high-strength wovens or multi-layered composites, naturally take more time and resources to produce. Think about the qc, the quality control. Good manufacturers invest heavily in testing to make sure every roll meets the specs – tensile strength, puncture resistance, flow rate, UV stability. This qc adds value, ensuring the fabric performs as expected, but it also adds to the production cost. You’re payin’ for that reliability.

And then, there’s gettin’ it to ya – the logistics. Geotextiles are bulky. They come in big, heavy rolls. Shipping these things around ain’t cheap, ‘specially if they’re comin’ from a factory halfway across the country or even overseas. Fuel costs for trucks and ships, warehousing, handling at distribution centers – it all adds up. If you’re in a remote location, expect the shipping to be a more significant part of the final price. I remember a project way up in the mountains; the cost of just transporting the geotextile rolls up the narrow, winding roads was a serious consideration in the budget. So, when you get a quote, make sure you know if shipping is included or if it’s an extra. These “hidden” costs can sometimes catch people by surprise. It’s all part of the journey from factory to field, and every step has its price. Understanding these layers helps you appreciate what goes into the final figure when you’re looking at different options, especially for critical applications like those needing specialized geotextile protection for critical infrastructure.

How Your Project Changes What You Pay: Application Specifics

The type of project you’re tacklin’ has a massive say in what kind of geotextile you need, and therefore, how much you’re gonna spend. It’s not a one-size-fits-all deal. If you’re just puttin’ in a small French drain in your backyard, you’ll likely be lookin’ at a relatively lightweight, inexpensive non-woven fabric. Its main job is filtration, stop a bit of silt, and it doesn’t need superhero strength. The cost here will be pretty minimal. But, change that to buildin’ a new highway or a railway line, and you’re in a whole different league. Here, the geotextiles are workin’ under immense loads, day in and day out. They need to provide serious reinforcement, separation of subgrade and base course, and long-term stability. This means heavy-duty, high-strength woven or robust non-woven geotextiles, engineered to specific stress and strain tolerances. These are premium products, and their price reflects that level of performance and the rigorous testing they undergo.

Consider erosion control – this is a huge area for geotextiles. If it’s a gentle slope with minor water runoff, a basic erosion control blanket or a medium-weight non-woven might do the trick. But what if you’re dealin’ with a steep riverbank gettin’ hammered by floodwaters, or coastal defenses? That’s where specialized solutions like expert geotextile mattress solutions for erosion control come in. These systems, which might be filled with concrete or allow vegetation to establish, are designed for serious protection. They need to be incredibly durable, resistant to abrasion, and often UV stable if exposed. The material cost here will be higher, but the cost of not using them – potential land loss, property damage – is way, way higher. We’ve seen proven geotextile mattress projects for water infrastructure that have saved millions in the long run by preventing catastrophic failures.

Then there’s stuff like landfills or containment ponds for industrial waste. The geotextiles used here have to do more than just separate or reinforce; they often act as a protective cushion for impermeable geomembranes, preventin’ punctures that could lead to environmental contamination. These applications demand geotextiles with specific puncture resistance, chemical resistance, and long-term durability, sometimes for decades. When we’re talkin’ about specialized geotextile protection for critical infrastructure, the specs are tight, and the quality has to be top-notch, so the price will reflect that. Even in landscaping, a high-end landscape architect might specify a premium weed barrier that’s tougher and lasts longer than the cheap stuff from the garden center, especially under expensive paving or in prominent public spaces. So, the bigger the risk, the higher the performance demand, the more critical the application, the more you should expect to invest in the right geotextile. It’s about matchin’ the material to the mission.

Smart Shopping: Getting Good Geotextile Without Breakin’ the Bank

Everyone wants a good deal, right? But when it comes to geotextiles, “cheapest” doesn’t always mean “best value.” Smart shoppin’ here is about findin’ the right balance between cost, performance, and longevity for your specific needs. The absolute first thing is to resist the urge to just grab the lowest price per square yard without lookin’ at the specs. That bargain basement roll might be too thin, tear easily, or not have the right filtration properties for your job. If it fails prematurely, you’re lookin’ at excavation, removal, replacement, and doin’ the whole job again. That ain’t savin’ money; that’s a headache and a much bigger bill in the end. I’ve seen it happen – a client tried to save a few bucks on an under-slab geotextile, and within a year, they had issues with moisture and settling. Penny wise, pound foolish, as they say.

So, how do you shop smart? Start by really understandin’ what you need. What’s the fabric gotta do? Separate? Filter? Reinforce? Drain? What are the site conditions like? Poor soil? Heavy loads? Lots of water? Once you know the performance requirements, you can start comparin’ products. Look closely at the data sheets. Compare things like grab tensile strength, tear strength, puncture resistance, permittivity (for water flow), and apparent opening size (AOS, for filtration). Make sure you’re comparin’ apples to apples. One supplier’s “heavy-duty” might be another’s “medium-duty.” It’s also worth lookin’ into the long-term picture. Opting for highly durable geotextile mattresses to transform terrains might mean a slightly higher upfront cost, but if it lasts twice as long or significantly reduces maintenance, it’s the more economical choice over its lifespan.

Don’t be afraid to ask questions. Talk to suppliers, get their recommendations, but also do your own homework. Sometimes, a specialized product, even if it seems pricier initially, can save you money elsewhere. For example, some geotextile systems are designed for faster or easier installation, which reduces labor costs. Or, as highlighted by resources talking about the advantages and applications of geotextile mattresses, understanding these benefits can show how a particular system offers better overall value. Readin’ up on a geotextile mattress uses, benefits & installation guide can also arm you with the knowledge to make a more informed decision, rather than just lookin’ at the price per roll. And always get multiple quotes for the same, or very similar, specified product. Prices can vary between suppliers, even for the same item, due to their own overheads, stock levels, or delivery charges. Just make sure the quotes are for a directly comparable product and include all costs, like shipping and any taxes.

Countin’ Pennies: Budgeting for Geotextiles in Your Grand Designs

Alright, so you’re plannin’ your project, whether it’s a simple driveway or a complex bit of civil engineering. You know you need geotextile, but how do you actually budget for it accurately? It’s more than just lookin’ up a price per roll; there are a few things to factor in to avoid any nasty surprises later on. First and foremost, you gotta know how much you actually need. This sounds obvious, but mistakes here can be costly. Start with accurate measurements of the area to be covered. Length times width gives you the basic square footage or square meterage. But then, think about overlaps. Geotextiles usually need to be overlapped at the seams – typically anywhere from 12 to 36 inches, dependin’ on the application and the specific fabric recommendations. This means you’ll need more fabric than just the raw area calculation. Also, factor in a bit for waste and odd shapes. It’s rare for a project area to be a perfect rectangle, so you’ll have cuts and offcuts. Addin’ a contingency, say 5-10%, to your calculated quantity is usually a smart move. Nothin’s worse than runnin’ short mid-project and havin’ to place another small, expensive order with extra shipping.

Next up is the actual cost of the fabric itself. As we’ve discussed, this depends on the type, weight, strength, and any special features. Once you’ve specced the right geotextile for your job, get quotes from a few suppliers. Make sure these quotes are for the exact same product or truly equivalent alternatives. Check the unit of sale – is it per square yard, per square meter, or per roll? And what’s the size of the roll? This is important for comparing prices fairly. Remember that a raised-pattern geotextile mattress that cuts costs 40% might offer savings not just in material but potentially in installation too, which ties into the next point.

Don’t forget about the cost of gettin’ it there and puttin’ it in. Delivery charges can be significant, especially for large, heavy rolls or if you’re in a remote location. Always ask for delivery to be quoted separately or ensure it’s included in the material price. Then there’s installation. Are you DIY-ing it? If so, your cost is mainly your time, but also any tools you might need like utility knives, stakes, or maybe even rental equipment for larger jobs. If you’re hirin’ a contractor, labor will be a major part of the budget. The ease of installation can vary between different geotextiles; some lighter, more flexible ones might be quicker to lay than very stiff, heavy ones. This is where insights from someone like Li Gang, an expert geotextile mattress manufacturing leader, can be invaluable as their experience often extends to how product design impacts field installation. Finally, think about any associated materials – anchor pins, staples, or fill material if you’re using something like a geotextile mattress. Add all these up, and you’ll get a pretty solid idea of what that geotextile part of your project is truly gonna set you back.

What’s the Geotextile Crystal Ball Say? Future Price Peeks

Tryin’ to predict future prices for anything can be a bit like guessin’ the weather, but there are some solid trends and factors in the geotextile world that give us a few clues about what might be comin’ down the pike. A huge one, as always, is the cost of raw materials. Polypropylene and polyester, the mainstays of geotextile production, are tied to oil and natural gas prices. So, if global energy markets get shaky or see big swings, expect that to ripple through to geotextile costs. Keepin’ an eye on general Geotextile Market Analysis reports can give you a broader picture of these underlying cost pressures. If analysts are predictin’ higher polymer costs, it’s a fair bet that geotextile prices might nudge up too.

Technological advancements in manufacturing are another key area. As manufacturers find more efficient ways to produce fabrics, or develop new polymers that are cheaper or offer better performance for the same cost, this could put downward pressure on prices for certain types of geotextiles, or at least give you more bang for your buck. We’re always seein’ new innovations, whether it’s improved weaving techniques, faster non-woven production lines, or the development of more eco-friendly materials. These advancements often aim to improve performance or reduce costs, or sometimes both! The market for specific products, like those detailed in the Nonwoven Geotextiles Market Research, will evolve as these technologies become more widespread.

Regional demand and supply also play a big part. If there’s a construction boom in a particular area, like that covered by the North America Geotextiles Market Report, demand for geotextiles will go up. If supply can’t keep pace, prices might rise locally. Conversely, if a market cools down, suppliers might have more inventory and could offer more competitive pricing to shift it. Global shipping costs and trade policies can also throw a spanner in the works or smooth things out. If it suddenly gets much more expensive to ship materials across oceans, that cost will likely be passed on. And let’s not forget about specialized products like those in the Geotextile Tubes Global Market Report. As awareness and adoption of these niche solutions grow, their production might scale up, potentially leading to more stable or even lower prices over time. There’s also a general trend towards more durable and long-lasting solutions, as people realize the whole-life cost benefits. This might mean initially higher prices for premium products, but savings in the long run. It will be interestin’ to see how all these factors mix together in the comin’ years. One thing that a Geotextile Fabric Market Report might highlight is the increasing focus on geotextiles in infrastructure resiliency, which could drive demand for higher-spec, and potentially higher-cost, materials.

Some Questions Folks Often Ask (FAQs)

Q1: How much does basic geotextile fabric cost per square foot/meter?

A1: It really, really varies. A light-duty non-woven for simple garden use might be as low as a few cents per square foot, maybe $0.15 to $0.50. But a heavy-duty woven or a specialized geotextile mattress for serious civil engineering could be several dollars per square foot, sometimes even more when you factor in installation of complex systems. Best to get specific quotes for your project’s needs.

Q2: Is woven or non-woven geotextile more expensive?

A2: Generally, high-strength woven geotextiles can be more expensive than basic non-wovens due to their manufacturing process and the amount of polymer used for strength. However, high-performance non-wovens designed for specific filtration or cushioning can also command a premium. It’s less about “woven vs. non-woven” and more about the specific grade and performance characteristics.

Q3: Does buying geotextile in bulk save money?

A3: Almost always, yes. Suppliers usually offer discounts for larger quantities. A full roll will be cheaper per unit area than buying it by the cut yard, and buying multiple rolls or truckloads will typically get you even better pricing.

Q4: What are the “hidden” costs when buying geotextile fabric?

A4: Delivery charges are a big one. Also, consider the cost of accessories like anchor pins or staples. If installation is tricky or requires specialized equipment, that can add to the overall project cost, even if the fabric price itself seems low. Don’t forget potential waste from cuts and overlaps needs to be factored into your quantity calculation.

Q5: How does the application affect the cost of geotextile fabric?

A5: Big time. A demanding application like reinforcing a highway subgrade or providing expert geotextile mattress solutions for erosion control on a major river requires a much higher-spec, and therefore more expensive, geotextile than a simple landscape weed barrier. The more critical the performance, the higher the likely cost.

Q6: Where can I find pricing for specialized systems like vegetation geotextile mattress systems?

A6: For specialized systems, you’ll almost always need to contact the manufacturer or a certified distributor directly. These are often engineered solutions, and the “cost” includes not just the material but sometimes design support or specific installation guidance. They aren’t usually an off-the-shelf price.

Q7: Will oil prices significantly change what I pay for geotextile?

A7: They can, yeah. Since most geotextiles are made from petroleum-based polymers, significant or sustained changes in oil prices tend to filter through to raw material costs for manufacturers, which can then affect the price you pay. It’s often a lagging effect, not instantaneous.