Geotextile Concrete Mattress Applications and Installation Techniques

Key Takeaways

- Geotextile concrete mattresses are basically special fabric bags filled with concrete, and they’re real good for stoppin’ soil erosion.

- They work by creatin’ a strong, flexible cover over the ground that lets water out but keeps the dirt in.

- You see ’em used in places like riverbanks, slopes, and around pipes to keep everything stable.

- They’re pretty easy to put in, last a long time, and can even help plants grow back.

- Lots of good reasons to use ’em: they’re tough, good for the environment, and save money over time.

What Exactly are Geotextile Concrete Mattresses and Why’re They So Good?

Alright, so you’ve heard the term “geotextile concrete mattress” bandied about, maybe on a construction site or in some engineering discussion, and you’re thinkin’, “what in the world is that?” Well, lemme tell ya, it ain’t somethin’ you sleep on, that’s for sure. These things are serious bits of kit for lookin’ after our ground. Imagine a super tough, special kind of fabric, right? This fabric, the “geotextile” part, is designed to be strong, let water pass through, but hold back soil particles. Now, this fabric is made into a sort of double-layered quilt or mattress shape. The clever bit is that the space between these two layers gets filled with a specially mixed concrete, or grout as we often call it in the biz. Once that concrete sets, you’ve got yerself a flexible, yet incredibly robust, protective layer. We can Transform Terrains with Durable Geotextile Mattresses, makin’ unstable ground much more secure.

So, why’re they so good? Well, the main thing is how they strengthen soil solutions. Bare soil, especially on slopes or near water, is always at risk of gettin’ washed or blown away. This erosion can cause massive problems – landslides, damage to buildings, loss of good farmland, you name it. A geotextile concrete mattress acts like armor for the soil. It holds everything in place, even when there’s heavy rain or fast-flowin’ water tryin’ to shift it. The concrete gives it weight and strength, while the geotextile fabric underneath makes sure the soil particles don’t just wash out from beneath the concrete plates, which is somethin’ I’ve seen happen with less thought-out solutions, lemme tell ya. It’s a common mistake to just plonk down concrete without considerin’ what’s happenin’ underneath with fine particles. The geotextile is key for that filtration and separation, preventin’ that slow undermining that can lead to failure down the line. These mattresses are designed to be permeable, so water pressure doesn’t build up behind or under them, which is another big plus compared to solid concrete walls that can crack under hydrostatic pressure. They’re a bit of a game changer ’cause they combine the best of both worlds: the flexibility of a fabric with the strength of concrete, adaptin’ to the contours of the land instead of fightin’ ’em. This flexibility also means they can handle a bit of ground settlement without crackin’ up like a rigid concrete slab would. It’s a really smart system when you think about it, kinda mimics natural armorin’ like a turtle’s shell, but for the earth.

How These Mattresses Actually Stop Dirt from Movin’ Around

Now, let’s get into the nitty-gritty, the real mechanics of how these geotextile concrete mattresses work their magic to stop erosion. It ain’t just about plonkin’ down a heavy thing on the dirt, though the weight certainly helps. The process is a bit more clever than that. As I mentioned, you’ve got that high-strength geotextile fabric, usually woven or non-woven polypropylene or polyester, formed into a mattress with compartments. When these compartments are filled with cementitious grout, they create a series of interconnected concrete blocks, but they’re still held together by the fabric. This structure is key. The Advantages and Applications of Geotextile Mattresses in Erosion Control are numerous precisely because of this design.

First off, the weight of the concrete-filled mattress provides immediate stability. It resists the forces of water current, wave action, or even just gravity pullin’ soil down a slope. Think of it like a really heavy blanket that just won’t budge. But it’s more than just weight. The individual concrete blocks, because they’re contained by the fabric, can articulate. This means the whole mattress can conform to the shape of the ground, even if it’s a bit uneven or settles over time. This is a massive advantage over traditional rigid concrete linings which can crack and fail if the ground underneath shifts even a little. I’ve seen it countless times: a beautiful-lookin’ concrete channel that’s all cracked up after a few years ’cause the ground wasn’t perfectly stable. These mattresses avoid that. The geotextile fabric itself plays a couple of vital roles. It acts as a filter, allowin’ water to seep out from the soil beneath without carryin’ away the fine soil particles. This prevents that build-up of hydrostatic pressure that can otherwise lift or break erosion control structures. It also separates the concrete from the underlying soil, preventin’ the soil from bein’ scoured out from underneath the blocks. The surface texture of the mattress, which can be designed with different patterns, also helps to slow down water flow across the surface, reducin’ its erosive power. Some types are even designed to trap sediment and allow vegetation to grow through, which adds even more stability and makes the whole thing look a lot more natural over time. It’s a really robust system, built to last for decades with minimal fuss.

The Cool Things That Make Geotextile Concrete Mattresses Special

There’s a bunch of reasons why folks in my line of work get pretty excited about geotextile concrete mattresses. They ain’t just another erosion control method; they got some really standout features that make ’em the go-to solution for a lot of tough situations. One of the biggest things is their flexibility. I mentioned it before, but it’s worth sayin’ again. Unlike big, solid slabs of concrete that are rigid and unforgivin’, these mattresses can drape and conform to all sorts of uneven ground. Think riverbanks with all their natural curves, or slopes that aren’t perfectly smooth. The mattress, ’cause it’s made of interconnected concrete-filled cells within fabric, can settle and move a bit with the earth without breakin’ apart. This is super important, ’cause ground ain’t always stable, ya know? You might get a bit of settlement over time, and these mattresses can handle that, which saves a heap of trouble and repair costs down the line.

Then there’s the permeability and filtration. This is where that special geotextile fabric really shines. It’s designed to let water pass through it, which is a huge deal. If you just put a solid barrier, water can build up behind it, create a load of pressure, and eventually cause the whole thing to fail. Been there, seen that. But with these mattresses, water from the soil can seep out slowly and safely, relievin’ that pressure. And while it lets the water out, it keeps the fine soil particles in. That’s the filtration part. You don’t want the soil washin’ out from underneath your protection, ’cause then it’ll just collapse. Some systems are specifically Advanced Filtration Geotextile Mattress Systems, designed for spots where this is extra critical. Strength and longevity are also big pluses. The concrete provides the muscle, resistin’ abrasion from water, debris, even ice in cold places. And the geotextile fabric is tough stuff too, resistant to UV rays, chemicals, and biological degradation. So these things are built to last, often for many, many years with very little maintenance. And talkin’ about costs, some designs, like the Raised-Pattern Geotextile Mattress Systems, can even cut overall project costs by up to 40% compared to traditional methods. That’s a big number when you’re talkin’ large scale projects. They often need less ground preparation, are quicker to install, and ’cause they last so long, the whole life-cycle cost is often lower. It’s a package of benefits that’s hard to beat, honestly.

Where You See These Mattresses Doin’ Their Job in Real Life

You’d be surprised at all the different places these geotextile concrete mattresses pop up. They’re not just for one specific problem; they’re kinda like a Swiss Army knife for soil stabilization and erosion control. One of the most common places you’ll see ’em is on slopes. Any steep bit of ground, whether it’s a railway embankment, a roadside cuttin’, or just a natural hillside that’s prone to slippin’, can benefit. Sometimes they even use Advanced Vegetation Geotextile Mattress Systems for Slope Stability that are designed so plants can grow right through ’em. Once the roots take hold, the slope becomes even more stable, and it looks a whole lot nicer too, blendin’ back into the environment. It’s a great way to get engineering and nature workin’ together. I’ve seen some really impressive results where a bare, erodin’ slope turns into a green, stable feature in just a few seasons.

Riverbanks and shorelines are another biggie. Fast-flowin’ rivers or wave action can really eat away at banks, threatenin’ property and infrastructure. Layin’ these mattresses along the water’s edge, sometimes even a bit into the water, provides a real tough shield. They can handle the constant attack from the water and stop the bank from collapsin’. Similarly, in coastal areas, they’re used to protect against storm surges and tidal erosion on beaches or around harbors. You’ll also find them linin’ channels, culverts, and spillways. These are structures designed to carry water, often at high speeds, so they need serious protection to stop ’em from scourin’ out. The mattresses provide a durable, flexible linin’ that can take the punishment. Many Proven Geotextile Mattress Projects for Water Infrastructure showcase just how effective they are in these situations. And it’s not just about big, natural features either. They’re super useful for protectin’ Critical Infrastructure like pipelines, bridge abutments (the supports at each end of a bridge), and foundations of structures built near water or on unstable ground. If a pipeline gets undermined by erosion, or a bridge support starts to fail, that’s a massive problem. These mattresses offer a reliable way to armor these vital assets and make sure they stay put. Basically, anywhere you’ve got soil that needs to stay where it is, especially if there’s water involved, these mattresses are a top contender for the job. From big civil engineerin’ projects to smaller local council works, they’re makin’ a real difference.

Puttin’ Them In: What’s the Deal with Installin’ These Mattresses?

Okay, so now you know what these geotextile concrete mattresses are and why they’re so useful, you’re probably wonderin’ how they actually get ’em in place. It’s not as complicated as you might think, but it does need to be done right for ’em to work properly. The Geotextile Mattress Uses, Construction, Benefits & Installation Guide gives a pretty good overview, but I can give ya the practical rundown from what I’ve seen on site. First up is gettin’ the ground ready – site preparation, we call it. This usually involves clearin’ any vegetation, loose rocks, or debris from the area where the mattress is gonna go. Then, the surface needs to be graded, smoothed out as much as possible to the desired shape or slope. You want a reasonably even surface for the mattress to lie on, so it makes good contact with the ground. If there’s any really soft spots, they might need a bit of extra work, maybe some compaction or a base layer of gravel, to make sure everything’s stable. Attention to detail here really pays off later.

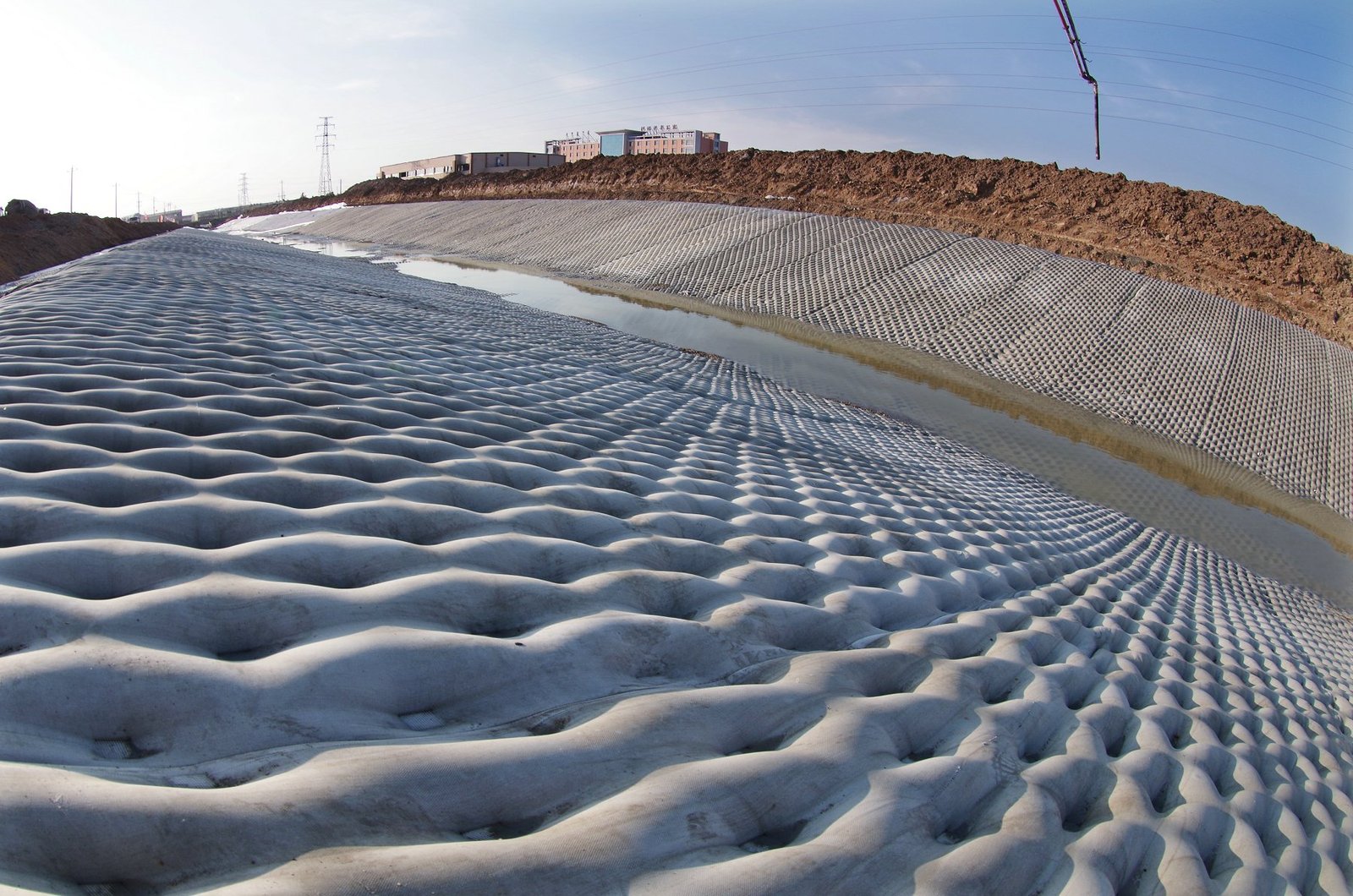

Once the ground’s prepped, the mattress itself, which often comes in big rolls or panels of the double-layered fabric, is deployed. The Construction Workers Installing Geotextile Mattress for Erosion Control (as shown in the image below) will unroll or lay out these fabric forms over the prepared area. They’ll be anchored securely at the top of the slope or along the edges to stop ’em from movin’ around during the next stage. Then comes the fillin’ part. This is where the “concrete” bit of “geotextile concrete mattress” comes in. A special mix of cement grout – which is basically a very flowable concrete – is pumped into the mattress. There are fillin’ ports built into the fabric, and the grout is injected until all the cells or compartments within the mattress are full. It’s important to get an even fill, without any big air pockets. You’ll often see the fabric bulge up as it fills, takin’ on its final shape.

After fillin’, the mattress needs to cure. This is where the grout hardens and gains its strength. Sometimes, especially in hot or dry weather, you might see a Worker Applying Water to Geotextile Mattress for Erosion Control – this is to help with the curin’ process, keepin’ it moist so the concrete cures properly and doesn’t crack. The time it takes to cure can depend on the specific grout mix and the weather conditions, but once it’s fully hardened, you’ve got a super tough, flexible protective layer ready to do its job. The beauty of it is that it’s often a quicker process than traditional methods like cast-in-place concrete or layin’ lots of individual riprap stones. Less machinery, often less labor, and it can be done in trickier access spots too.

So Many Good Reasons to Pick a Geotextile Concrete Mattress

When you’re lookin’ at ways to sort out erosion or make ground more stable, there’s usually a few options on the table. But, lemme tell ya, geotextile concrete mattresses bring a whole load of good reasons to the party, makin’ ’em a top choice for engineers and project managers, myself included. One of the biggest plus points, and somethin’ that’s gettin’ more and more important these days, is the environmental benefits. Traditional hard armorin’ solutions can be pretty harsh on the local ecosystem. Big concrete channels, for example, don’t offer much for wildlife. But these mattresses, especially the ones designed to allow vegetation growth, are a different story. They can actually help habitats recover. By stoppin’ soil erosion, they prevent sediment from cloggin’ up waterways, which is great for fish and other aquatic life. And when plants grow through them, they provide cover and food for insects and small animals. It’s a much gentler approach to engineering, workin’ with nature instead of against it.

Then there’s the money side of things – the economic benefits. While the upfront cost might sometimes look similar to other methods, the long-term savings can be massive. These mattresses are built tough. They last for ages – we’re talkin’ decades – with very little need for maintenance or repairs. Compare that to, say, constantly havin’ to replace eroded soil or fix cracked concrete, and you can see how the costs add up with other solutions. Plus, the installation process itself can be quicker and need less heavy machinery, which saves on labor and equipment hire. Some Geotextile Mattress Uses can also reduce the amount of excavation needed, further cuttin’ down on costs and environmental impact. Durability in harsh conditions is another huge advantage. Whether it’s freezin’ cold winters, scorchin’ hot summers, fast-flowin’ water full of debris, or even exposure to chemicals, these mattresses can take a beatin’ and keep on performin’. The materials they’re made from are chosen specifically for their resilience. I’ve seen ’em hold up in places where other systems would’ve given up the ghost years ago. And finally, just their sheer versatility is a massive plus. They can be tailored for so many different situations – steep slopes, flat areas, underwater, curvy riverbanks – you name it. This adaptability means you don’t need a dozen different products; this one system can often solve a whole range of erosion and stabilization problems. It really simplifies the design and construction process.

Makin’ ‘Em Right: What Goes into a Good Quality Mattress?

Now, not all geotextile concrete mattresses are created equal, ya know? Just like with anythin’ else, the quality of what goes into makin’ ’em and how they’re put together makes a huge difference to how well they perform and how long they last. It all starts with the materials. The geotextile fabric itself has to be top-notch. We’re talkin’ high-tensile strength stuff, usually woven or non-woven polypropylene or polyester. It needs to be resistant to tearin’, stretchin’, UV degradation from sunlight, and any chemicals it might come into contact with in the soil or water. If the fabric ain’t up to scratch, the whole thing can fail prematurely. Then there’s the concrete mix, or the grout as it’s properly called. This ain’t just your standard bag of cement from the hardware store. It’s a specially designed mix, often with admixtures to improve its flowability (so it fills all the little nooks and crannies of the mattress), reduce shrinkage as it cures, and increase its final strength and durability. The exact mix will often be tailored to the specific job – for example, if it’s goin’ to be underwater, they’ll use a mix that can cure properly in those conditions.

The manufacturing process of the fabric mattress itself is also critical. The seams need to be super strong, ’cause they’ll be under a lot of stress when the grout’s bein’ pumped in. The spacing of the internal ties or baffle walls that create the individual cells needs to be precise to ensure the mattress inflates to the correct thickness and the concrete blocks are uniform. Quality control is a big part of this. Good manufacturers, like those guided by experts such as Li Gang: Expert Geotextile Mattress Manufacturing Leader, will have rigorous testin’ procedures at every stage, from checkin’ the raw materials to inspectin’ the finished fabric forms before they leave the factory. This ensures consistency and reliability. And of course, there are industry standards and specifications that these products often need to meet, especially for big public works projects. There’s been a real push for better standards, like the talk around A New Specification for Geotextile Grout-Filled Mattresses, ’cause everyone in the industry wants to ensure these systems are designed and installed to the highest possible level. As an engineer, it gives you confidence when you know a product has been made to these high standards. It means it’s more likely to do the job it’s supposed to do, and keep doin’ it for a long, long time. You don’t want to be cuttin’ corners when it comes to protectin’ important assets or preventin’ landslides, that’s for sure.

What’s Next for Geotextile Concrete Mattresses in Keepin’ Soil Safe?

The world of geotextile concrete mattresses ain’t standin’ still, no sir. Just like with any good bit of engineering, people are always lookin’ for ways to make ’em even better, more efficient, and suitable for even more jobs. We’re seein’ some real cool innovations in materials. That means stronger, more durable geotextiles, maybe even ones made from recycled materials to make ’em more eco-friendly. And on the concrete side, there’s ongoing research into new grout formulations – stuff that’s even stronger, cures faster, or has a lower carbon footprint. Some folks are experimentin’ with different cell shapes and patterns within the mattress to improve how they interlock or how they encourage vegetation. It’s all about fine-tunin’ the design to get the absolute best performance for specific situations. You can bet if there’s a way to make ’em lighter to transport, or quicker to fill, someone’s workin’ on it.

The market for these things is definitely on the up. Reports like the Concrete Mattress Market Research Report and analysis on the Global Concrete Mattress Market show that more and more people are recognizin’ the benefits. As we face more extreme weather events due to climate change – think more intense rainfall, bigger storm surges – the need for robust erosion control is only gonna grow. And these mattresses are a perfect fit for that challenge. They’re also playin’ a bigger role in sustainable development. Because they can be designed to work with nature, supportin’ vegetation and protectin’ habitats, they fit well with greener approaches to construction and infrastructure protection. I reckon we’ll see ’em bein’ used in even more creative ways in the future, maybe combined with other eco-engineering techniques to create really resilient and environmentally friendly solutions. For anyone lookin’ into these solutions, it’s always a good idea to chat with folks who really know their onions and can provide Expert Geotextile Mattress Solutions tailored to your specific site and needs. The technology keeps advancin’, and stayin’ up to date with the latest developments can make a big difference to the success of a project. The future looks pretty solid, or should I say, flexibly solid, for these amazing bits of kit.

Frequently Asked Questions (FAQs)

- Q1: What exactly is a geotextile concrete mattress?

A: It’s basically a big, specially made fabric “bag” or mattress, with compartments inside. This fabric (the geotextile) is then filled with a type of liquid concrete called grout. Once it hardens, you get a strong but flexible protective layer for the ground. - Q2: How long do these mattresses last?

A: They’re designed to be super durable. We’re talkin’ many years, often decades! The exact lifespan depends on the site conditions and the quality of the materials and installation, but they generally last a real long time with little maintenance. - Q3: Can plants grow through a geotextile concrete mattress?

A: Yes, some types are specifically designed for that! They have spaces or are made with materials that allow vegetation to take root and grow through. This helps make the area look more natural and actually adds to the stability. - Q4: Are they bad for the environment?

A: Actually, they’re often much better for the environment than traditional hard concrete solutions. They can help reduce soil erosion, which is good for water quality, and the types that allow plants to grow can even help create new habitats. - Q5: Is installin’ them difficult?

A: Not really, especially compared to some other methods. The fabric forms are laid out, then filled with grout. It usually requires specialized equipment for pumpin’ the grout, but it can often be quicker and need less heavy machinery than, say, pourin’ a massive concrete slab or placin’ lots of big rocks. - Q6: Where are geotextile concrete mattresses most commonly used?

A: You see ’em a lot on riverbanks, coastlines, channels, and slopes – basically anywhere you need to stop soil from washin’ or slidin’ away. They’re also great for protectin’ things like pipelines and bridge foundations. - Q7: Are they expensive?

A: The initial cost can vary, but when you look at how long they last and how little maintenance they need, they often work out cheaper in the long run compared to methods that need constant repair or replacement. Some designs can even be cheaper upfront too.