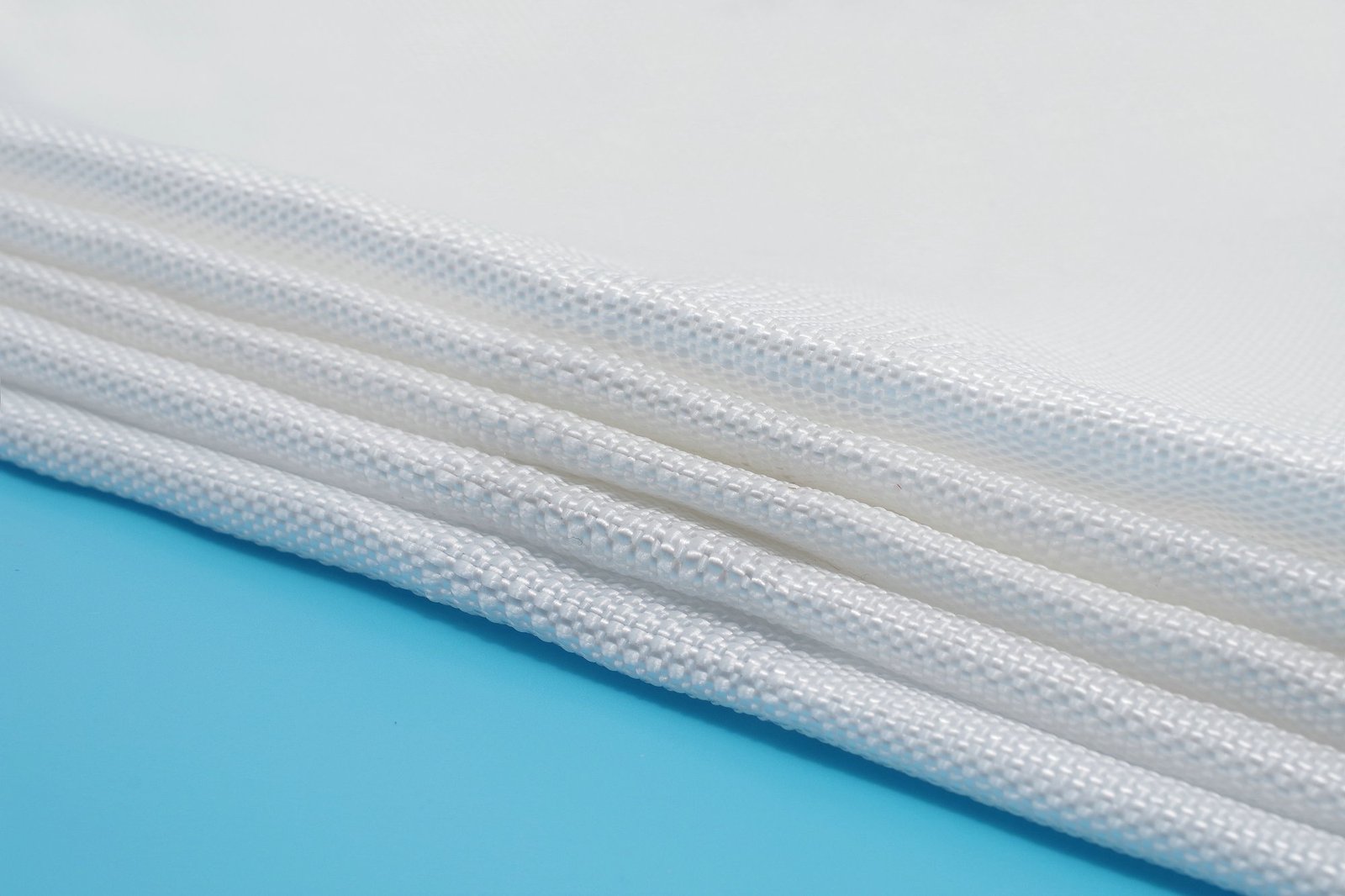

Advanced Filtration Geotextile Mattress Systems

Superior Drainage Solutions That Prevent Erosion & Sedimentation

Our filtration systems solve critical water management challenges with high-strength permeable materials and proprietary technology. Built with our complete production chain, these mattresses maintain optimal flow while preventing soil erosion. With 48-hour nationwide delivery and 40,000m² daily production capacity, we ensure your projects stay on schedule without sacrificing quality.

PRODUCT FEATURES

Superior Filtration for Water Management Infrastructure

Our systems address four critical challenges infrastructure managers face:

Efficient Installation

UV-resistant materials maintain structural integrity for 25+ years, even under harsh conditions, eliminating costly replacement cycles.

Efficient Installation

Pre-fabricated modules enable installation of up to 4,000m² daily, with 20 production lines ensuring consistent product availability.

Customization

R&D team develops tailored solutions for unique geological challenges, ensuring optimal performance in complex environments.

Quality Assurance

Rigorous laboratory testing verifies each production batch meets national standards for strength, permeability, and stability.

Advanced Geosynthetic Dewatering Systems

Our high-performance dewatering filter bags provide superior filtration solutions for drainage channels, dewatering projects, and lake reinforcement applications. Engineered with premium geotextile materials, our systems deliver exceptional particle retention while maintaining optimal flow rates, ensuring long-term infrastructure protection and environmental compliance.

Superior Filtration Geotextile Mattress Systems

Our advanced systems represent a decade of dedicated technology innovation. Here’s why professionals trust us:

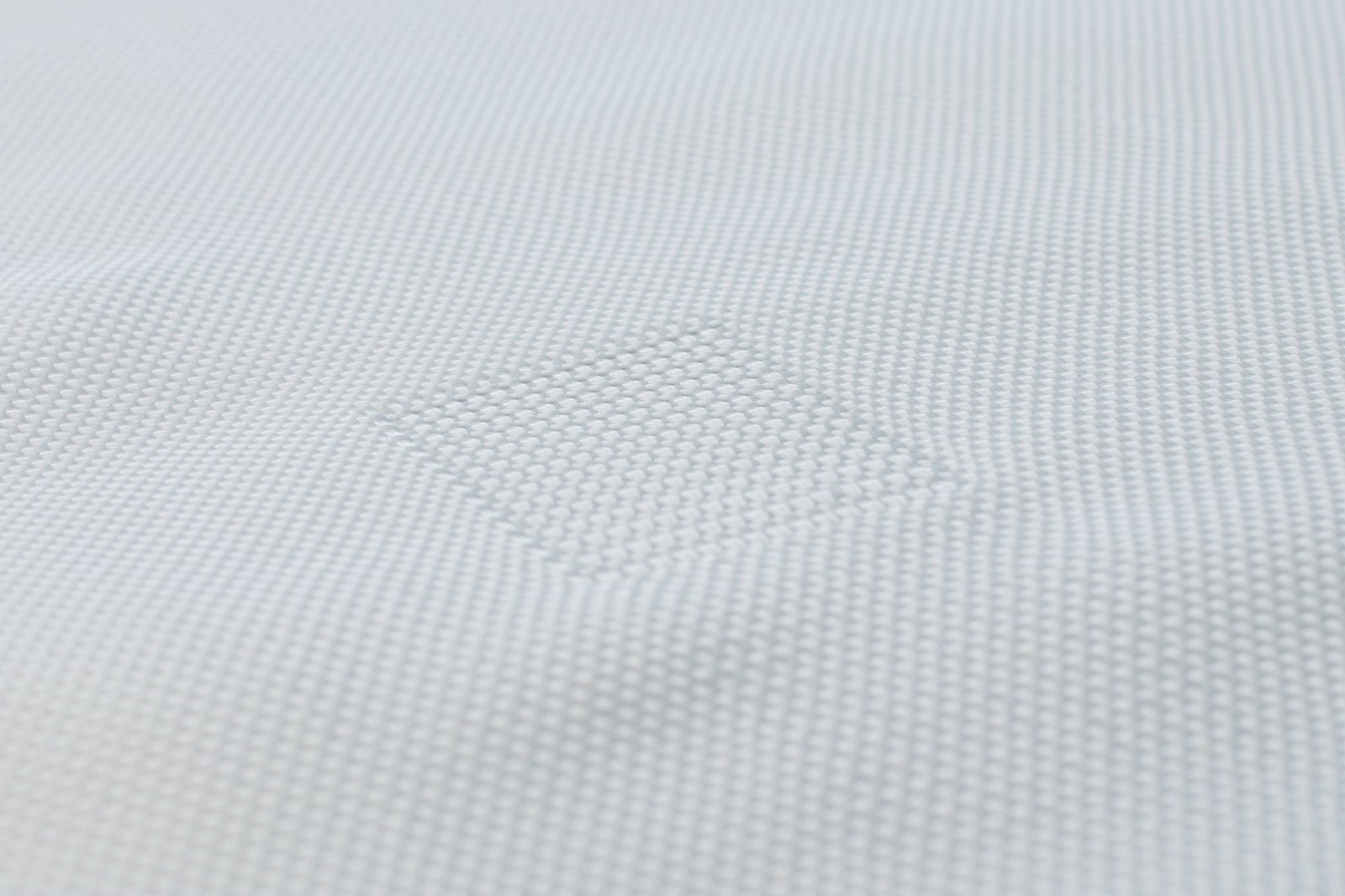

Superior Filtration Efficiency

Our engineered pore structure optimizes flow while capturing sediment particles as small as 0.15mm. Our precision-manufactured layers maintain performance even during high-volume events, preventing downstream contamination.

Extended Service Life

UV-stabilized materials and reinforced construction deliver 25+ years of consistent performance—double the lifespan of conventional alternatives, significantly reducing maintenance and replacement costs.

Rapid Installation Process

Factory-prepared modules enable installation rates of 3,000-4,000m² daily. With 150 production lines running at full capacity, we support your largest projects without delays, reducing timelines by up to 50%.

Environmental Compatibility

Our technology prevents erosion and sedimentation while maintaining natural flow patterns, preserving aquatic ecosystems and supporting regulatory compliance. Each batch undergoes strict testing to ensure environmental safety.

Versatile Application Range

From agricultural drainage to lake lining, our adaptable design delivers consistent performance across diverse conditions, allowing standardization across multiple infrastructure applications.

Cost-Effective Solution

Reduced maintenance, extended service life, and faster installation deliver substantial lifecycle savings. Our integrated production chain provides factory-direct pricing, typically reducing lifetime costs by 30-40%.

High Hydraulic Performance

Optimized flow characteristics ensure maximum drainage capacity even during peak events. Our innovative raised pattern design manages water energy more effectively than flat surfaces, protecting underlying infrastructure.

Customizable Configurations

Our R&D center can tailor solutions to your exact specifications. Available in various permeability ratings, dimensions, and strengths, we ensure optimal filtration for each unique application.

Proven Track Record

Successfully implemented in over 150 major projects across China, our systems demonstrate reliable real-world performance. With 5,000+ successful implementations covering 10,000+ kilometers of channels, you can trust our consistent results.

Filtration Geotextile Mattress Technical Parameters

Our detailed guides provide complete instructions for every phase of installation. Each manual includes equipment requirements, connection techniques, and troubleshooting solutions for various applications.

Site Preparation Guidelines

Proper site preparation is critical for optimal filtration performance. Our guidelines cover essential aspects including:

Channel gradient specifications for optimal flow

Base layer compaction standards for stability

Junction preparation for seamless connections

Root and debris removal for unobstructed flow

Subgrade preparation for various soil conditions

Edge treatment for secure channel integration

Concrete Mixing Specifications

Our engineered connection methods ensure continuous filtration performance across the entire system:

Overlap specifications for various flow conditions

Seaming techniques for permanent installation

Anchor spacing based on flow velocity

Junction reinforcement for high-stress points

Terminal connection details for inflow/outflow points

Quality control procedures for connection integrity

Field Inspection Procedures

Our systematic inspection framework helps project managers verify installation quality:

Pre-installation material inspection checklists

Alignment and gradient verification methods

Connection integrity assessment techniques

Flow testing procedures for performance validation

Documentation templates for quality assurance

Potential failure point identification guidelines

Maintenance Recommendations

Maximize the service life of your filtration geotextile mattress system:

Scheduled inspection frequencies (quarterly recommended)

Sediment removal guidelines for optimal performance

Cleaning procedures for filtration surface maintenance

Flow obstruction prevention methods

Long-term performance monitoring protocols

Emergency response procedures for extreme events

Engineering Excellence in Filtration Solutions

Don’t risk project delays or system failures. Our team brings 10 years of specialized experience to your water management challenges. Contact us today for a free consultation and customized proposal.