Geotextile GSM Meaning, Specs, Performance & Applications Guide

Understanding GSM in Geotextiles: A Complete Guide

Key Takeaways

| Aspect | Details |

|---|---|

| GSM Definition | Grams per Square Meter – measures fabric weight and density |

| Typical Range | 100-600 GSM for most civil engineering applications |

| Impact on Performance | Higher GSM = greater strength, durability, and filtration |

| Cost Factor | GSM directly affects material costs and project budgets |

| Selection Criteria | Soil type, load requirements, and environmental conditions |

| Testing Standards | ASTM D5261 and ISO 9864 for accurate measurement |

What GSM Actually Means in Geotextile Applications

GSM stands for “grams per square meter” – it’s the standard measurement that tells you how much a geotextile fabric weighs per unit area. Think of it like this: if you cut out exactly one square meter of fabric, GSM tells you how many grams that piece would weigh on a scale.

Most engineers use GSM as their primary indicator for fabric strength and performance. A 200 GSM geotextile contains twice as much material as a 100 GSM version of the same fabric type. This extra material typically translates to better tensile strength, puncture resistance, and overall durability.

The measurement isn’t just about weight though – it directly correlates with how well the fabric performs under stress. Higher GSM fabrics resist tearing better, last longer under heavy loads, and provide superior filtration in demanding soil conditions. I’ve seen projects fail because contractors chose fabrics with insufficient GSM ratings for their specific applications.

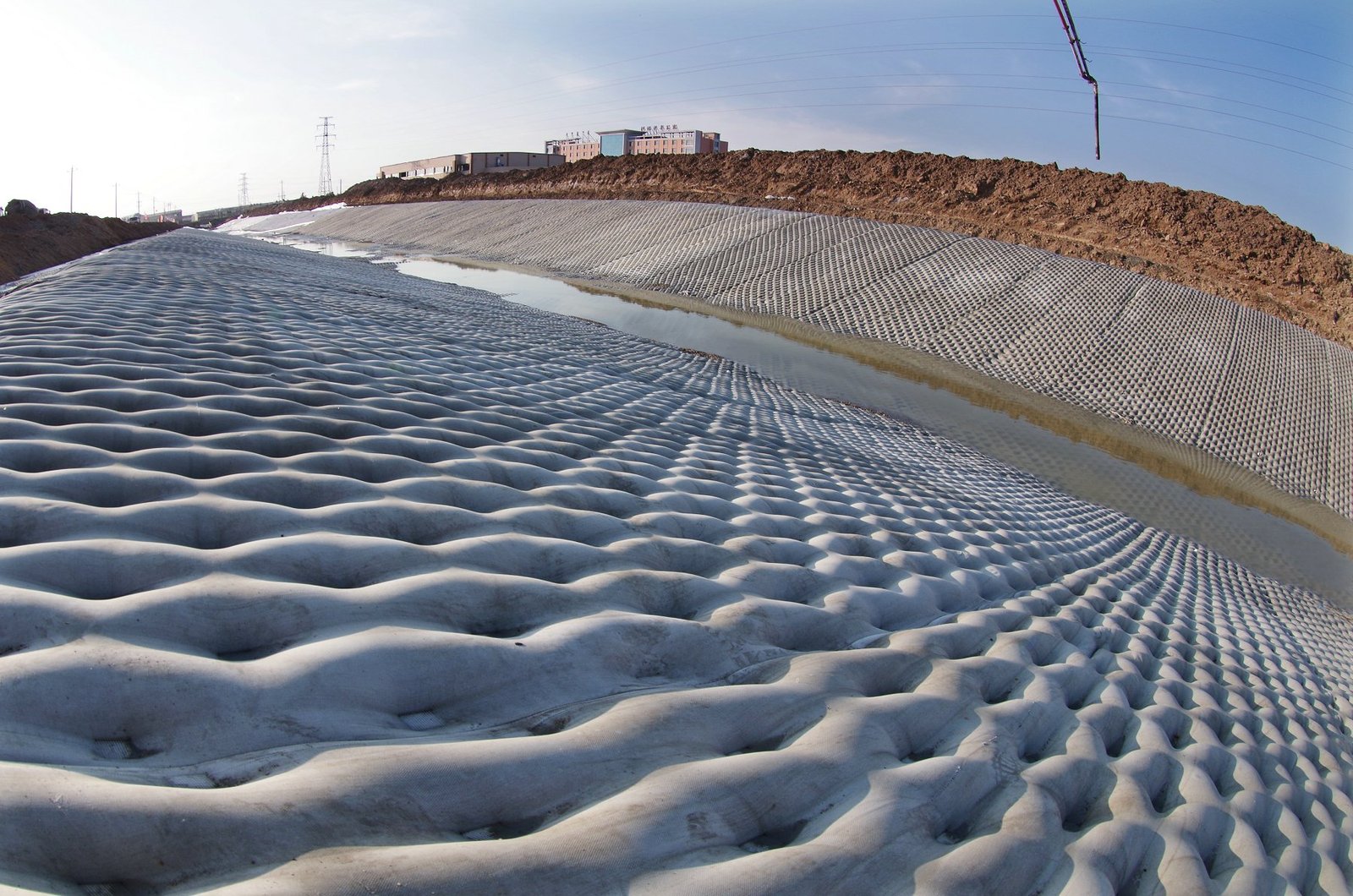

Geotextile mattress systems rely heavily on proper GSM selection to achieve their intended performance targets. The wrong GSM choice can compromise an entire infrastructure project.

How GSM Impacts Geotextile Strength and Performance

GSM directly determines how much punishment your geotextile can take before failing. In my experience working with various soil stabilization projects, fabrics below 150 GSM often struggle in heavy-duty applications like road construction or slope reinforcement.

The relationship between GSM and performance isn’t always linear though. A 400 GSM woven geotextile might outperform a 500 GSM nonwoven fabric in certain applications due to manufacturing differences. The fiber type, weaving pattern, and treatment processes all influence final performance characteristics.

Puncture resistance increases dramatically with higher GSM values. I’ve observed that fabrics around 300-400 GSM can withstand moderate stone impacts during backfill operations, while lighter fabrics often tear under similar conditions. This becomes critical in filtration geotextile mattress installations where rocks and debris are common.

Tensile strength also scales with GSM, but the improvement varies by fabric construction. Woven geotextiles typically show more predictable strength increases compared to nonwoven varieties as GSM rises.

GSM Standards and Testing Methods for Geotextiles

Professional GSM testing follows specific protocols to ensure consistency across manufacturers. ASTM D5261 provides the standard method for determining mass per unit area of geotextiles. The test involves cutting precise samples, conditioning them at specific temperature and humidity levels, then weighing them with calibrated equipment.

Testing laboratories must maintain strict environmental controls during GSM measurements. Temperature variations of just a few degrees can affect results, especially with synthetic fabrics that expand or contract with heat. Most reliable tests occur at 21°C with 65% relative humidity.

ISO 9864 offers an alternative testing standard that’s widely accepted internationally. The key difference lies in sample preparation and conditioning time – ISO requires longer stabilization periods before measurement. Both standards produce reliable results when followed correctly.

Quality control during manufacturing involves continuous GSM monitoring. Manufacturers typically test every production run to ensure consistency within ±5% of target specifications. Standard geotextiles undergo this rigorous testing to meet industry requirements.

Choosing the Right GSM for Your Project Requirements

Project-specific GSM selection requires careful analysis of soil conditions, load requirements, and expected service life. Light-duty applications like landscape fabric typically use 100-150 GSM materials, while heavy construction projects demand 300+ GSM fabrics.

Soil type plays a huge role in GSM selection. Sharp, angular aggregates can puncture lower GSM fabrics during installation or service. I always recommend increasing GSM by 50-100 units when working with crushed stone or recycled concrete aggregate.

Load calculations help determine minimum GSM requirements for structural applications. Road subgrade stabilization typically requires 200-300 GSM, while railroad applications often specify 400+ GSM for adequate performance. The Wisconsin concrete pavement specifications provide excellent guidelines for infrastructure applications.

Environmental factors also influence GSM selection. UV exposure, chemical contact, and temperature cycling all affect fabric longevity. Higher GSM fabrics generally resist environmental degradation better than lighter alternatives.

Vegetation geotextile mattress systems require specific GSM ranges to balance plant growth with soil retention – typically 200-350 GSM works best for most slope stabilization projects.

Cost Analysis: How GSM Affects Your Project Budget

GSM directly impacts material costs – expect to pay roughly 15-25% more for every 100 GSM increase in fabric weight. However, this simple math doesn’t tell the complete financial story for most projects.

Higher GSM fabrics often reduce installation costs by eliminating the need for additional protection layers or reinforcement. A 400 GSM fabric might cost 40% more than a 200 GSM alternative, but could eliminate the need for cushioning materials that cost even more.

Labor efficiency improves with appropriate GSM selection. Lighter fabrics tear more easily during installation, requiring repairs that slow progress and increase costs. I’ve seen projects where using inadequate GSM resulted in 20-30% installation time increases due to constant repairs.

Long-term costs favor higher GSM fabrics in most applications. Premature failure of underspecified geotextiles can cost 5-10 times the original material savings when replacement and associated construction disruption are factored in. Iowa’s special permit requirements for oversized loads often apply to geotextile replacement projects.

Bulk purchasing of higher GSM materials often yields better per-unit pricing than smaller quantities of lighter fabrics, particularly for large infrastructure projects.

Installation Techniques Based on GSM Weight Classifications

Different GSM ranges require distinct installation approaches to achieve optimal performance. Light fabrics (100-200 GSM) need careful handling to prevent damage during placement, while heavy fabrics (400+ GSM) require specialized equipment for efficient installation.

Handling procedures change significantly with GSM weight. Fabrics below 150 GSM can often be placed by hand with proper techniques, but materials above 300 GSM typically require mechanical placement to avoid worker injury and ensure proper positioning.

Overlap requirements vary by GSM rating. Lighter fabrics need larger overlaps to distribute stress effectively, while heavier fabrics can use shorter overlaps without compromising performance. Most specifications call for 150-300mm overlaps depending on GSM and application.

Anchor spacing adjustments become necessary with different GSM values. Heavier fabrics require closer anchor spacing to prevent wind uplift during installation, especially in exposed areas. Geotextile mattress installation projects demonstrate proper anchoring techniques for various GSM ranges.

Equipment selection depends heavily on fabric GSM. Lighter materials can be installed with basic construction equipment, while heavy fabrics might require specialized spreaders or lifting devices to maintain installation speed and quality.

GSM Performance in Different Environmental Conditions

Environmental conditions significantly affect how different GSM ratings perform over time. UV exposure, temperature cycling, and moisture exposure all impact fabric longevity differently based on GSM values.

High-temperature environments favor higher GSM fabrics due to increased thermal mass and resistance to heat damage. I’ve observed that fabrics below 200 GSM often show accelerated degradation in desert climates or near heat sources like paved surfaces.

Freeze-thaw cycles affect lighter GSM fabrics more severely than heavier alternatives. Ice crystal formation can damage fiber bonds in low GSM materials, while higher GSM fabrics typically maintain structural integrity through multiple freeze-thaw events.

Chemical resistance generally improves with higher GSM values, though fiber type remains the primary factor. The additional material thickness in higher GSM fabrics provides more protection against chemical penetration and degradation.

Biological resistance varies by GSM, with denser fabrics typically resisting rodent damage and root penetration better. However, very high GSM fabrics might impede beneficial biological processes in some applications. MnDOT’s geotextile specifications address these environmental considerations for riprap applications.

Advanced geotextile mattress systems incorporate GSM selection based on specific environmental challenges at each project site.

Common GSM Selection Mistakes and How to Avoid Them

The most frequent mistake I encounter is selecting GSM based solely on initial cost rather than total project value. Contractors often choose the minimum acceptable GSM to save money upfront, then face expensive failures later.

Over-specification represents another common error – using 500 GSM fabric where 250 GSM would perform adequately wastes money and might actually reduce performance in some applications. Heavier fabrics can impede drainage or create installation difficulties unnecessarily.

Ignoring local soil conditions during GSM selection causes many project failures. Sandy soils require different GSM considerations than clay soils, and installers must account for particle size, angularity, and chemical composition during fabric selection.

Inadequate consideration of installation stresses leads to fabric damage before the geotextile even begins service. Sharp aggregate, heavy equipment traffic, and construction activities can damage lighter GSM fabrics beyond repair during installation.

Failure to account for long-term loading changes results in premature fabric failure. Projects that start with light loads but will experience heavier traffic later need GSM selection based on ultimate loading conditions, not initial requirements.

Expert geotextile solutions can help avoid these common pitfalls through proper project analysis and GSM recommendation based on specific site conditions and performance requirements.

Frequently Asked Questions

What GSM rating should I use for road construction?

Road construction typically requires 200-400 GSM depending on traffic loads and soil conditions. Light residential roads can use 200-250 GSM, while heavy commercial or highway applications need 350-400 GSM fabrics.

How do I measure GSM accurately in the field?

Field GSM measurement requires cutting precise samples and using calibrated scales. Most contractors rely on manufacturer certifications rather than field testing due to equipment requirements and testing complexity.

Can I use lower GSM fabric with additional layers?

Multiple layers of lower GSM fabric don’t always equal the performance of single higher GSM layers. Interface friction between layers can reduce overall effectiveness, making single-layer higher GSM solutions more reliable.

Does GSM affect water permeability?

GSM impacts permeability, but fabric construction method has greater influence. Nonwoven fabrics maintain better permeability than woven fabrics at similar GSM values due to their pore structure.

What’s the maximum useful GSM for geotextiles?

Most applications see diminishing returns above 600 GSM. Installation becomes difficult, costs increase dramatically, and performance benefits plateau. Specialized applications might use higher GSM, but 600 GSM handles most demanding requirements.

How does GSM relate to fabric thickness?

GSM and thickness correlate but aren’t directly proportional. Fabric construction, fiber density, and manufacturing processes all affect the GSM-to-thickness relationship. Always specify both parameters for critical applications.