Geotextile Mattress Customization and Design Options Guide

Key Takeaways

- Specificity is Key: Geotextile mattresses ain’t one-size-fits-all; customization makes them work right for each specific project site.

- Fabric Matters: The type of geotextile fabric (woven, non-woven, its strength and permeability) is a major customization point impacting performance.

- Size and Shape: Dimensions, thickness, and even surface patterns can be adjusted to fit the exact needs of slopes, channels, or shorelines.

- Fill ‘Er Up Right: The grout mix inside the mattress can be customized for strength, setting time, or environmental factors.

- Added Features: Options like openings for vegetation or specific filter points allow for ecological integration and enhanced drainage.

- Process: Customization involves careful site assessment, engineering design, and working closely with experienced suppliers or manufacturers.

Understanding Geotextile Mattress Basics for Customization

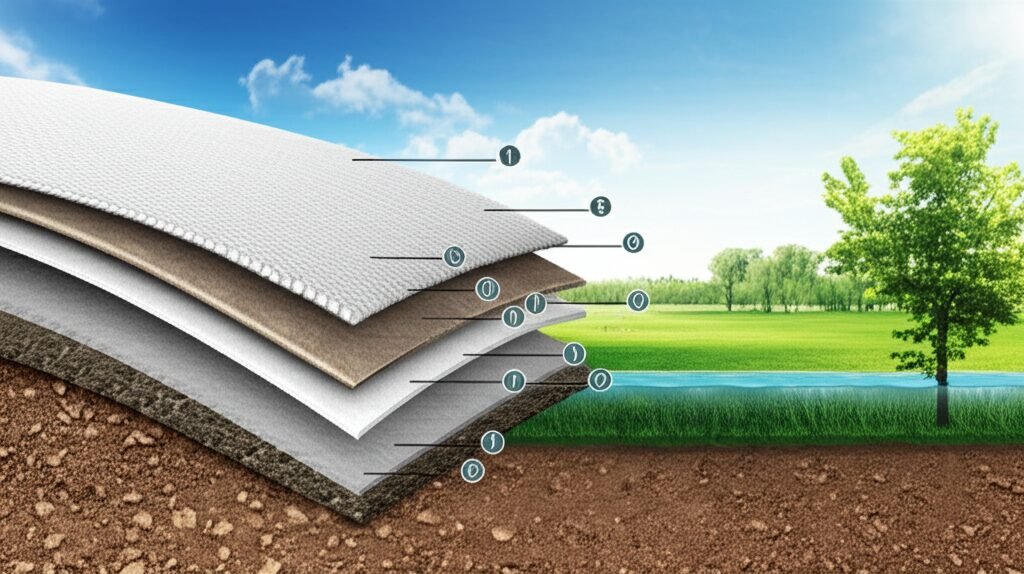

So, what exactly is a geotextile mattress? Think of it like a big, flat bag made from special engineered fabric, a geotextile. This bag gets placed where you need to stop soil washing away, like on a riverbank or a steep slope, and then it’s filled, usually with a concrete grout mix. This makes a heavy, flexible, but quite strong protective layer. It’s different from just dumping rocks (riprap) or pouring solid concrete, cause it uses this fabric technology to hold everything together and sometimes let water through in a controled way. Its a pretty neat solution for lots of erosion problems. The main idea is covered in guides like this Geotextile Mattress Uses, Construction, Benefits & Installation Guide. You see them used all over, protecting pipeline crossings, lining channels, holding up shorelines, that sort of thing.

Why bother customizing them though? Well, every single site is difference, right? You got different soil types, different water speeds, different slope angles, maybe plants you want to grow back, or maybe its underwater half the time. A standard mattress might work okay sometimes, but tailoring it means you get the best possible performance and often save money cause your not over-engineering it or using materials that ain’t quite right for the job. Customization lets you dial in the exact strength, flexibility, drainage, and even how it looks. Maybe you needs extra tough fabric cause the water flow is super fast, or maybe the soils really fine so you need a fabric weave that wont let it wash through. This ability to tweak things is what makes durable geotextile mattresses such a versatile tool for engineers. It’s about getting the specifications just perfect for that specific place, not just grabbing something off the shelf.

Think about it like this, you wouldn’t wear the same coat in summer and winter, would ya? Same idea here. A geotextile mattress for a slow-moving canal needs different properties than one getting hammered by waves on a coastline. Customization could mean changing:

- The type of fabric used (strength, UV resistance, how much water it lets through).

- The overall size and shape of the mattress sections.

- How thick the mattress is when filled.

- The mix design of the grout used to fill it.

- Adding special features like holes for planting vegetation.

Getting these details right is crucial for making sure the protection lasts a long time and does its job proper.

Tailoring Fabric Selection: The First Step in Customization

The fabric itself, the geotextile, is maybe the most important part you can customize. It’s the skin of the whole system. Get the fabric wrong, and the whole mattress might fail before it’s supposed to. Ther’s loads of different types of geotextile fabrics and properties, and choosing the right one depends completely on the project. You gotta think about things like tensile strength – how hard can you pull it before it rips? This is important if the mattress is gonna be under stress, like on a steep slope or holding back soil pressure. Then there’s puncture resistance; you don’t want sharp rocks or debris poking holes in it, specially during installation.

Another biggie is permeability. How easily does water pass through the fabric? Sometimes you want water to seep out from the soil behind the mattress to relieve pressure, so you need a fabric that lets water through but stops the soil particles washing out. This is where advanced filtration geotextile mattress systems come in, using fabrics specifically designed for that filtering job. Other times, maybe in a channel lining, you want it pretty impermeable. And don’t forget UV resistance! If the mattress is gonna be exposed to sunlight for years, the fabric needs to handle that without breaking down and becoming brittle. Woven fabrics often have high strength, while non-woven fabrics might be better for filtration and drainage cause of their structure. Selecting the right type involves understanding these trade-offs.

From experience, working with experts like Li Gang, who really knows geotextile manufacturing, you learn that subtle differences in the fabric make a huge difference on site. It’s not just about woven vs. non-woven. It’s about the polymer type (polypropylene, polyester), the weight of the fabric (grams per square meter), the manufacturing process, even the color can matter for UV absorption or aesthetics. An expert can look at the site conditions – the soil report, the water flow data, the environmental regulations – and recommend a fabric that balances performance, lifespan, and cost. Somtimes a slightly more expensive fabric initially saves a fortune down the line by lasting longer or preventing a costly failure. It’s about making an informed choice based on the engineering requirements, not just picking the cheapest option. You gotta match the fabric to the forces its gonna face.

Adjusting Mattress Dimensions and Thickness

Once you’ve got an idea about the right fabric, the next thing to customize is the physical size and shape of the thing. Geotextile mattresses aren’t just poured like concrete; they come in panels or sections typically manufactured off-site then stitched or joined together before filling. This means you can specify the exact length, width, and crucially, the thickness you need. Why does this matter? Well, the dimensions dictate how much area each panel covers and how they fit together on the specific geometry of your site – think curves around a river bend or fitting neatly into a channel profile. Making panels too small means more joints (potential weak spots), too big and they might be difficult to handle and conform to the ground contours. Its a balance.

The thickness is super important too cause it directly relates to the weight and stability of the finished mattress. A thicker mattress holds more grout, making it heavier and more resistant to being lifted or shifted by water currents or wave action. For really demanding spots, like coastal defenses or fast-flowing rivers experiencing scour, you’ll likely need a thicker, heavier mattress. For gentler slopes or canals, a thinner mattress might be perfectly adequate and more cost-effective. The thickness also influences the overall flexibility; a thinner mattres can often conform better to uneven ground. Getting the thickness right is a key part of the advantages and applications of geotextile mattresses in erosion control. It’s about calculating the forces acting on the mattress and designing it to resist them, without going overboard and wasting material and money.

Comparing this approach to traditional methods sheds some light. Poured concrete is thick and rigid, often prone to cracking if the ground underneath shifts a bit. Riprap (loose rock) can be effective but requires large amounts of specific sized stone, which isn’t always available or economical, and individual stones can get dislodged. A geotextile mattress, customized for thickness, offers controlled weight and stability but retains some flexibility thanks to the fabric formwork. This flexibility allows it to handle minor ground settlement better than rigid concrete. Some sources even compare geotextile mattresses vs concrete directly on cost and durability. Customizing the thickness lets you optimize this balance between weight, flexibility, and cost for the specific site demands. It allows a more engineered solution than just guessing how much rock to dump.

Custom Grout Mixes: Beyond Standard Fill

The fabric shell is only half the story; what you fill it with, the grout, is just as critical and offers loads of customization possibilities. Standard grout is usually a mix of cement, sand, and water, sometimes with additives like fly ash. It provides the weight and locks the mattress into its final shape. But “standard” isn’t always best. Depending on the project, you might need somethin’ special. For instance, if you need the mattress to gain strength really quickly, maybe because of tidal flows or expected heavy rain right after installation, you can specify a rapid-hardening cement mix. Or if the mattress is going to be permanently underwater, especially in saltwater, you might need a grout mix designed to resist sulphate attack or chloride ingress to ensure its longevity.

The function and benefits of grout go beyond just weight. The grout’s properties influence the final mattress’s stiffness, its resistance to abrasion from moving water and sediment, and its overall durability. You could specify higher strength grout for areas with high abrasion potential, like the outside of a river bend. There’s also growing interest in more environmentally friendly grout mixes, perhaps using alternative cementitious materials or recycled components, especially for sensitive locations. The key カスタム (custom) point here is that the grout isn’t just filler; its an engineered material that contributes significantly performance.

One expert tip I always stress is checking grout compatibility with your chosen fabric before starting the main works. Some grout mixes, particularly very fine ones or those with certain chemical additives, might not flow properly within the specific fabric structure, or they could even clog the fabric pores if filtration is needed. Running some simple flow tests or checking the manufacturer’s recommendations is crucial. You need the grout to completely fill the mattress void without excessive pressure buildup or bleed-out. Customizing the grout involves:

- Strength: Matching compressive strength to expected loads.

- Durability: Selecting mix components for chemical resistance (saltwater, sulfates).

- Flowability: Ensuring the mix can be pumped and fills the fabric form completely.

- Setting Time: Adjusting for site logistics and environmental conditions (e.g., tides).

- Environmental Considerations: Exploring greener alternatives where appropriate.

Getting the grout mix right ensures the filled mattress behaves exactly as intended in its specific environment. Some suppliers even offer pre-packaged grout mixes tailored for mattress applications, taking some guesswork out.

Incorporating Specific Features: Filtration and Vegetation Openings

Beyond the basic fabric and fill, geotextile mattresses can be customized with special features built right in. Two of the most common and useful additions are filter points and openings for vegetation. Filter points are basically small, deliberately designed permeable areas within the largely impermeable grout-filled mattress. They allow groundwater pressure from behind the mattress to dissipate slowly and safely. Without them, water pressure could build up and potentially destabilize the slope or structure the mattress is protecting. Advanced filtration geotextile mattress systems are specifically designed with these filter points integrated, often using a combination of fabric types or special inserts to achieve controlled drainage while preventing soil loss. The size, spacing, and location of these filter points can be customized based on soil type and expected hydraulic conditions.

Then you have vegetation openings. Instead of a solid grout surface, these mattresses are designed with regular gaps or pockets left unfilled or filled with soil. This allows plants to establish roots through the mattress and into the soil beneath. Advanced vegetation geotextile mattress systems are superb for projects where you want erosion control plus ecological restoration. The vegetation adds stability over time as roots bind the soil, improves water quality, provides habitat, and just makes the whole thing look a heck of a lot nicer and more natural. You can customize the size and spacing of these openings depending on the type of vegetation you want to establish and the level of structural support required from the grout itself. It’s a way to get hard armor protection while working with nature, not against it.

The beauty of these features is they can often be combined. You might have a mattress with vegetation openings on the main slope face but incorporate filter points near the base where water pressure is likely highest. The design process involves looking at the site’s hydrology, ecology, and structural needs to determine the optimal configuration. For example:

- Riverbanks: Vegetation openings are great for aesthetics and habitat, filter points help manage fluctuating water levels.

- Channels: Might prioritize hydraulic efficiency (smoother surface) but could use vegetation on upper banks.

- Steep Slopes: May need more grout for stability, but could incorporate smaller vegetation pockets if desired.

This level of functional customization is a major advantage over simpler erosion control methods, offering solutions tailored not just for stability but for drainage management and ecological integration too, highlighting the clear advantages and applications in erosion control.

Pattern Variations: Raised vs. Flat Mattresses

Another way geotextile mattresses can be tailored is through their surface pattern or profile. After filling, they don’t all have to be perfectly flat and smooth. One common variation is the raised-pattern geotextile mattress, sometimes called a ‘cobblestone’ or ‘pillow’ mattress. This effect is created by internal restraining ropes or diaphragms within the fabric shell. When the grout is pumped in, these restraints pull the top and bottom layers of fabric together at regular intervals, creating a pattern of raised ‘pillows’ of grout separated by lower channels where the fabric is drawn together. Why do this? Well, this textured surface can offer several advantages depending on the situation.

The raised pattern increases surface roughness. In some applications, like channel linings or spillways, this increased roughness can actually help to slow down water flow and dissipate energy, reducing erosion potential further downstream. The channels between the pillows can also provide little niches that trap sediment and potentially offer better foothold for establishing vegetation compared to a completely smooth surface. Furthermore, the pattern itself can break up the monolithic appearance of a plain grout surface, making it look a bit more natural or aesthetically interesting. Some manufacturers even claim that these raised-pattern systems can cut costs significantly, perhaps due to optimized grout usage or simpler installation methods compared to other hard armor techniques, though you’d always want to verify this for your specific project.

Of course, a flat or uniform-thickness mattress has its place too. For applications where maximum hydraulic efficiency is needed (getting water to flow smoothly and quickly with minimal resistance), a flatter profile might be preferred. It can also be simpler to manufacture and potentially use slightly less fabric per square meter. The choice between a raised pattern and a flat profile comes down to the project’s specific hydraulic requirements, aesthetic goals, and any secondary benefits you might be looking for, like sediment trapping or vegetation support. Key considerations include:

- Hydraulic Performance: Does the application require low friction (flat) or energy dissipation (raised)?

- Stability: Does the interlocking nature of a raised pattern offer any additional stability benefits for the specific site conditions?

- Aesthetics: Which look is preferred or required by project stakeholders?

- Secondary Functions: Is sediment trapping or vegetation enhancement a goal?

- Cost: Comparing the installed cost per unit area for each option.

Like other aspects, the pattern is another lever you can pull during the design phase to fine-tune the mattress performance, as shown in various geotextile erosion control installations.

Custom Solutions for Specialized Applications

While channel lining and slope stabilization are common uses, the real power of customization shines when you get into specialized applications. Geotextile mattresses can be adapted to solve some really tricky erosion control and infrastructure protection problems where standard solutions just won’t cut it. Take shoreline protection, for example. Coastal environments face waves, tides, and potentially harsh saltwater exposure. Mattresses here might need extra thickness for weight against wave uplift, specialized saltwater-resistant grout, high-strength fabrics to handle abrasion from sand and shingle, and careful anchoring systems to keep everything in place. The flexibility of the mattress can also be an advantage here, allowing it to conform to shifting beach profiles better than rigid seawalls.

Another big area is protecting underwater infrastructure, like pipelines or bridge foundations, from scour. Scour happens when fast-moving water erodes the soil around a structure, potentially undermining it. Geotextile mattresses can be custom-designed to wrap around pipeline crossings or placed around bridge piers. They need to be heavy enough to resist the currents, flexible enough to install underwater (often with divers), and durable enough to last decades in that environment. Customization might involve unique shapes to fit around piers, specific filter fabrics to allow some water flow without soil loss beneath the mattress, or even integrating lifting loops to help with underwater placement. There are many proven geotextile mattress projects that showcase these kinds of specialized uses. Systems like Techrevetment formed concrete mattresses represent related innovations in formed mattress technology for demanding civil works.

Even things like anchoring methods can be customized. How the mattress is secured at its edges, particularly at the top of a slope (the crest) or the bottom (the toe), is vital for stability. Depending on the soil conditions and expected loads, custom anchoring solutions might involve trenching the edges in, using specialized mechanical anchors, or integrating the mattress with other geotechnical structures. An expert eye is needed here to assess the site and design edge details and anchorages that prevent undermining or flanking (erosion getting around the edges). This level of detail, tailoring not just the mattress body but how it integrates with the surrounding site, is what defines truly custom, effective solutions for critical infrastructure protection.

The Customization Process: Working with Experts

So how does this all come together on a real project? Customizing a geotextile mattress isn’t something you just order from a generic catalog like the ones showing general concrete mattress products. It starts with a thorough site investigation and a clear understanding of the problem you’re trying to solve. What are the soil conditions? Whats the water velocity or wave height? Are there environmental sensitivities? What’s the desired lifespan? You need good data upfront. This information feeds into the engineering design process. Engineers experienced with geosynthetics and hydraulics will analyze the data and determine the required performance specs: fabric strength, mattress thickness, grout properties, anchoring needs, any special features like filter points, etc.

This detailed specification is then taken to a reputable manufacturer or supplier who specializes in geotextile mattresses. This is where you discuss the fabric options, panel sizes, pattern choices, and manufacturing tolerances. Good communication between the designer and the manufacturer is essential to ensure the final product matches the design intent precisely. They can provide feedback on constructability and maybe suggest cost-effective alternatives that still meet the performance requirements. It’s a collaborative process. Getting expert geotextile mattress solutions often means involving the supplier early on. Techniques like using fabric formed concrete rely heavily on the interplay between the flexible formwork (the geotextile) and the fill material.

Finally, installation is key. Even the best custom-designed mattress won’t work if it’s installed poorly. Proper site preparation, correct panel placement and joining, careful grout pumping – it all matters. Quality control during installation ensures the mattress achieves its intended shape, thickness, and anchorage. Considering the geotextile mattress benefits for long-term performance means thinking about the whole lifecycle, from design through manufacturing to installation and even potential maintenance needs down the road. The whole point of customization is to optimize this entire process for the specific demands of the project, leading to a more effective, durable, and often more economical solution compared to off-the-shelf approaches. Working with experienced professionals at each stage – investigation, design, manufacturing, installation – is the best way to unlock the full potential of customized geotextile mattresses.

Frequently Asked Questions (FAQs)

Q1: Can any geotextile fabric be used for a mattress?

A1: No, not really. Fabrics used for mattresses need specific properties. They gotta be strong enough to contain the grout pressure during filling, durable enough for the site conditions (like UV or abrasion), and have the right permeability if drainage is needed. Usually, high-strength woven or specific composite geotextiles are used. The fabric choice is a major part of the customization.

Q2: How thick can a geotextile mattress be made?

A2: Thickness is customizable based on the project needs. They typically range from maybe 4 inches (100mm) up to 12 inches (300mm) or even more for really heavy-duty applications like coastal defense. The thickness directly affects the weight and stability, so engineers calculate the required thickness based on expected forces (water flow, waves etc.).

Q3: Is it difficult to install customized mattresses?

A3: Installation requires care and the right equipment, especially for filling with grout, but its not necessarily harder than standard mattresses. The main thing is having a good installation plan, proper site prep, and experienced crews. Custom shapes or features might require a bit more attention during placement, but the basic process of positioning the fabric and pumping grout remains similar.

Q4: Can you grow plants through any geotextile mattress?

A4: Only if it’s designed for it! Standard mattresses filled completely with grout won’t support vegetation. You need a mattress specifically customized with open pockets or areas filled with soil, like a vegetation geotextile mattress. These provide both erosion protection and allow plants to grow.

Q5: Is customizing a geotextile mattress much more expensive?

A5: It can be, but not always. While custom design and potentially specialized materials might increase the upfront cost per square meter compared to a hypothetical ‘standard’ product, customization often leads to better performance and a longer lifespan. It can also save money by optimizing material usage (e.g., not making it thicker than needed) or reducing future maintenance costs. You gotta look at the whole life-cycle cost. Sometimes a custom solution like a raised-pattern mattress might even offer cost savings over other traditional methods.