Geotextile Mattresses: The Best Erosion Control Barriers

Okay, lets get this sorted. What are we lookin’ at today? Ah, geotextile mattresses. Right, good stuff for stopping erosion. How do they actually work as a barrier? What makes ’em different from just chucking down some rocks? And where’re the best places to use ’em?

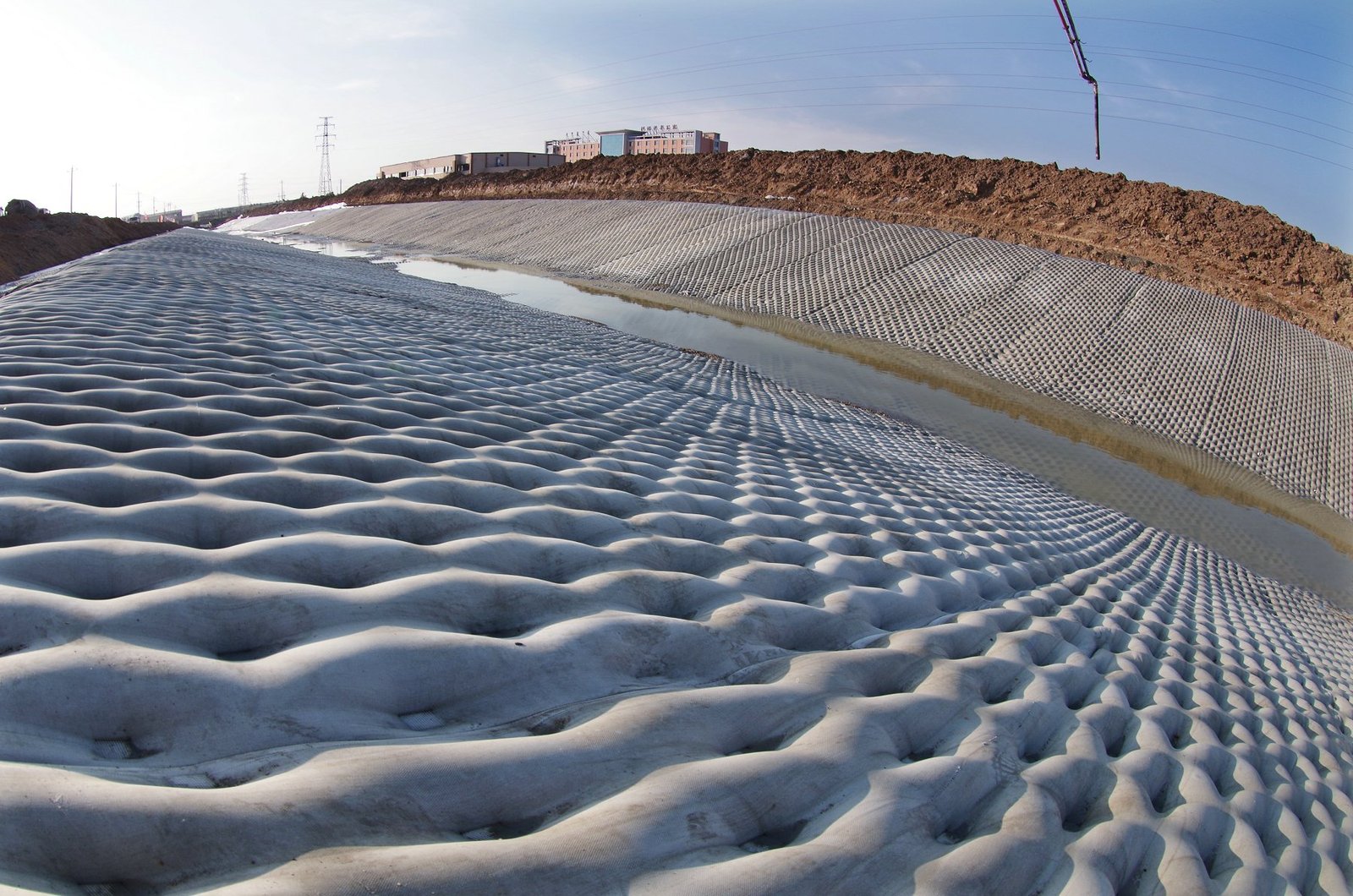

Well, basically, they’re like big fabric envelopes you fill up, usually with concrete or grout. This creates a heavy, yet kinda flexible, mat that holds the soil down. So, water can still seep through in a controlled way, which is important, but the soil itself stays put. Unlike riprap, which can shift about, these mattresses conform better to the ground and lock together. They’re brilliant for riverbanks, channels, slopes… anywhere water tries to wash away the land, really. It’s a solid way to Transform Terrains with Durable Geotextile Mattresses.

Key Takeaways:

- Core Function: Geotextile mattresses act as a protective layer, using their weight and structure to prevent water and wind from moving soil.

- How They Work: They consist of high-strength fabric layers sewn together, filled typically with concrete or grout, forming a flexible but heavy barrier.

- Key Benefit: They allow water to permeate slowly (filtration) while retaining soil particles, preventing erosion without causing water pressure buildup.

- Applications: Widely used on riverbanks, coastlines, channel linings, spillways, landfill caps, and slope stabilization.

- Advantage: Often more flexible and adaptable to ground contours than traditional ‘hard armor’ like concrete paving or riprap. Can integrate with vegetation.

- Installation: Involves site preparation, laying the mattress, filling it, and allowing it to cure. Proper installation is key to effectiveness.

What Exactly *Are* Geotextile Mattresses and How Do They Stop Erosion?

Alright, so you’ve heard the term, but what is a geotextile mattress? Think of it like a specially designed, super-tough fabric container. It’s usually made from two layers of strong synthetic fabric – geotextiles – sewn together in a specific pattern. This pattern creates compartments or pockets inside. You lay this ‘mattress’ down on the area you need to protect, like a slope or a riverbank thats starting to wash away. Then, you fill those pockets, typically pumping in a concrete grout mix or sand cement. Once that filling hardens, you’ve got a heavy, stable, but still somewhat flexible mat covering the ground. Its main job? To be a massive pain for erosion.

How does it stop soil movin’ around? It’s pretty straightforward, really. First, there’s the weight. A concrete-filled mattress is heavy. It physically holds the soil surface down, making it much harder for flowing water or even strong winds to pick up soil particles and carry them off. Imagine trying to blow away a heavy blanket versus a loose pile of dust – same idea. Second, it acts as a protective shield. The fabric and the hardened filling create a barrier between the erosive force (like river currents or surface runoff) and the vulnerable soil underneath. Water might flow over the mattress, but it can’t easily get at the soil to erode it. Its a bit like armour plating for the earth. This basic principle is covered well in this Geotextile Mattress Uses, Construction, Benefits & Installation Guide. I remember a job on a small channel where spring runoff used to chew away feet of bank every year; after laying down some mattresses, it just… stopped. The flow was still there, but the banks stayed solid.

The Nitty-Gritty: How Geotextile Mattresses Are Made and Why It Matters

So, we know they’re fabric bags filled with something heavy. But the details of how they’re made are actually pretty important for how well they work. The fabric itself, the geotextile, is key. It needs to be incredibly strong to hold the weight of the fill without ripping, especially during installation when it’s being pumped full of grout. It also needs to be durable enough to last for years, maybe decades, exposed to water, sunlight (UV radiation), and ground chemicals. Often, these are specialized woven or nonwoven polypropylene or polyester fabrics. Nonwovens are quite common, as highlighted in market research like this Nonwoven Geotextiles Market Research. The choice of fabric impacts strength, flexibility, and crucially, its permeability – how easily water can pass through, which we’ll talk more about later.

The way the two layers of fabric are joined together also matters. They’re sewn or bonded at intervals, creating that pattern of pockets or cells. The size and spacing of these connections determine how thick the mattress will be once filled and how flexible it remains. Smaller cells generally mean a more flexible mattress that can hug uneven ground better. Larger compartments might be used where more sheer weight is needed. The filling ports, little openings where the grout nozzle is inserted, need to be positioned correctly for efficient filling. Getting the manufacturing right relies on experience – people like Li Gang: Expert Geotextile Mattress Manufacturing Leader understand the nuances that ensure a quality product. It’s not just about sewing two bits of cloth together; it’s engineering a system designed to perform under specific stresses. Their strong construction means they can handle quite a bit of punishment once installed.

Putting Them to Work: Key Uses and Applications for Erosion Control

Where do you actually use these things? Well, pretty much anywhere you’ve got soil or sediment that wants to wander off because of water or wind. One of the biggest uses is protecting banks along rivers, canals, and streams. Fast-flowing water, boat wash, flood events – they all eat away at banks. Laying geotextile mattresses along the waterline and up the bank slope armours it effectively. You see loads of examples in Proven Geotextile Mattress Projects for Water Infrastructure. They’re also used extensively for coastal protection, guarding shorelines and estuaries against wave action and tidal currents.

Other common spots include:

- Channel Linings: To prevent erosion in drainage ditches, spillways, and culvert outlets.

- Slope Stabilization: On steep embankments for roads, railways, or around constructions sites to prevent landslides and surface wash-off, especially before vegetation gets established.

- Reservoir Edges & Dam Faces: Protecting against wave erosion in water storage areas.

- Pipeline Protection: Shielding underwater pipelines from scour caused by currents.

- Landfill Caps: As part of the capping system to prevent erosion of the cover layers.

Basically, any situation where you need Specialized Geotextile Protection for Critical Infrastructure or just need to keep soil in its place against the forces of nature, these mattresses are a potential solution. The Advantages and Applications of Geotextile Mattresses in Erosion Control are pretty wide-ranging. I worked on a project protecting bridge abutments once; the scour was getting serious, threatening the foundations. Mattresses were laid around the bases, filled, and the problem was solved much quicker and, honestly, probably cheaper than trying to build massive concrete collars underwater. They’re surprisingly versatile for lots of differnt places.

More Than Just a Barrier: The Role of Filtration in Geotextile Mattresses

Okay, here’s where geotextile mattresses get a bit more clever than just being heavy weights. Remember I mentioned the fabric’s permeability? That’s crucial because these mattresses aren’t usually designed to be totally waterproof barriers like a concrete slab. They are designed to let water through, but keep the soil behind. This is the ‘filtration’ aspect, and it’s super important, especially in places with fluctuating water levels or groundwater seepage. Think about a riverbank. Water level goes up, water soaks into the bank behind the mattress. Water level drops, that water needs to get back out. If the barrier was totally impermeable, you’d build up water pressure behind it, which could eventually push the whole mattress system out or cause other failures.

The geotextile fabric acts like a filter. Its pore structure is designed to be small enough to hold back the soil particles of the bank (preventing them washing through the mattress), but large enough to let water pass through relatively freely. This stops that hydrostatic pressure build-up. It allows the protected area to drain naturally. This dual function – barrier and filter – is a key advantage. Advanced Filtration Geotextile Mattress Systems are specifically engineered with fabrics that have optimal filtration properties for the type of soil being protected. You need the right balance; let too much fine soil through and you still get erosion behind the scenes, let too little water through and pressure builds up. Getting this right involves understanding soil mechanics and hydraulics – it’s why specialist design is often needed. Water can get thru, but the dirt stays put. Simple idea, but effective engineering.

Going Green: Using Vegetation with Geotextile Mattresses for Enhanced Stability

One of the really neat things about some geotextile mattress systems is their ability to work with nature, not just against it. While a freshly laid concrete-filled mattress might look a bit grey and industrial, they can be designed to encourage plant growth. How? Well, some mattress types are designed with pockets or openings specifically left unfilled or filled with soil/gravel instead of solid grout. Others have a fabric structure that retains enough moisture and fines to allow seeds, either sown deliberately or arriving naturally, to germinate and take root within the mattress structure itself.

Why bother with vegetation? Couple of big reasons. First, aesthetics. A vegetated mattress blends into the surrounding landscape much better than bare concrete or fabric. It looks more natural, which is often a requirement, especially in environmentally sensitive areas or public spaces. Second, and maybe more importantly from an engineering perspective, the plant roots add significant long-term stability. As roots grow through the mattress and into the soil beneath, they bind everything together even more strongly. This creates a composite system where the mattress provides the initial erosion protection, and the vegetation adds increasing reinforcement over time, plus further surface protection from rain splash and minor runoff. It’s a win-win. Systems like Advanced Vegetation Geotextile Mattress Systems for Slope Stability are designed specifically for this purpose. Plants really help alot in the long run, making the whole setup tougher and better looking.

Getting it Right: The Installation Process for Geotextile Mattresses

You can have the best geotextile mattress in the world, but if it’s not installed properly, it wont do its job. The process isn’t rocket science, but it needs care and attention to detail. It generally follows these steps, though specifics might vary depending on the site and the exact mattress type:

- Site Preparation: This is maybe the most critical step. The ground surface needs to be graded to the desired slope and profile, removing any big rocks, roots, or debris that could damage the fabric or leave voids underneath. A smooth, stable subgrade is essential. Sometimes a foundation trench is dug at the ‘toe’ or bottom of the slope to anchor the mattress securely.

- Laying the Mattress: The mattress panels, which often come in large rolls or pre-sewn sections, are unrolled or placed carefully onto the prepared surface. Adjacent panels need to be overlapped or sewn together according to the manufacturer’s instructions to ensure continuity. Anchoring pins might be used temporarily to hold it in place.

- Filling: This is usually done by pumping a fluid grout mix (sand, cement, water, maybe some additives) through the filling ports designed into the mattress. The pumping needs to be done systematically, often starting from the lowest point and working upwards, to ensure all the compartments fill evenly without trapping large air pockets. You gotta be careful not to over-pressurize and burst the fabric seams.

- Curing: Once filled, the grout needs time to harden and gain strength. This curing time depends on the grout mix and ambient conditions (temperature, humidity). During this period, the mattress shouldn’t be disturbed or subjected to heavy loads.

Detailed guidance, like this Geotextile Erosion Control: Mattress Installation & Benefits, is invaluable. From experience, rushing the site prep or fillin’ it up too fast are common mistakes that can compromise the whole system. Getting the levels right and ensuring good contact with the subgrade prevents water getting underneath and causing problems down the line. You often see crews carefully managing the process, as shown in images like this Aerial view of a geotextile mattress installation site.

The Advantages Stack Up: Why Choose Geotextile Mattresses?

So, why go for geotextile mattresses instead of other erosion control methods like traditional concrete paving, riprap (loose rock), or gabions (wire baskets filled with rock)? They offer a pretty compelling set of benefits in many situations. One of the big ones is flexibility. Unlike rigid concrete structures, a filled mattress can conform to slight irregularities in the ground and can tolerate minor settlement without cracking or failing. Its flexible nature is a real plus on less stable ground.

Here’s a quick rundown of the main advantages:

- Flexibility: Adapts to ground contours and minor settlements.

- Permeability/Filtration: Allows water drainage, preventing hydrostatic pressure buildup while retaining soil.

- Durability: High-strength fabrics and concrete fill provide long-lasting protection.

- Vegetation Potential: Can be designed to allow plant growth for enhanced stability and aesthetics.

- Defined Thickness: Provides a consistent layer of protection, unlike riprap which can have variable thickness.

- Installation Efficiency: Often quicker to install than cast-in-place concrete, especially underwater or in difficult access areas.

- Hydraulic Performance: Can be designed with specific surface roughness to manage water flow velocities.

Of course, they aren’t the solution for every problem. Really high-impact wave zones might still need massive concrete armour units, for example. And the cost compared to simple riprap can be higher initially, though potentially lower over the long term due to better performance and lower maintenance. Comparing them to alternatives like those mentioned in this blog on Concrete Mattress: A Game Changer in Erosion Control (note: ‘concrete mattress’ here often refers to these geotextile forms filled with concrete), highlights their specific niche. But for a huge range of applications, the blend of strength, flexibility, and filtration makes them a top choice. Exploring the Advantages and Applications of Geotextile Mattresses in Erosion Control further shows just how useful they are. Ultimately, they help Transform Terrains with Durable Geotextile Mattresses.

Finding the Right Fit: Considerations and Getting Expert Help

Choosing the right geotextile mattress system isn’t just a matter of picking one off the shelf. There are several factors to consider to make sure it performs as needed for the specific site conditions. You need to think about:

- Hydraulic Loads: How fast and forceful is the water flow it needs to resist? Is it constant current, wave action, or occasional flood runoff?

- Soil Type: What kind of soil is being protected? Fine silts need a fabric with smaller pores (tighter filter) than gravels or coarse sands.

- Slope Angle & Stability: Steeper slopes require mattresses with good anchorage and internal stability.

- Environmental Conditions: Is there significant UV exposure? Freeze-thaw cycles? Chemical exposure?

- Vegetation Requirements: Is vegetation integration desired or required?

- Durability Needs: How long does the protection need to last? What level of potential abrasion or impact might occur?

Because of these variables, it’s usually best to involve experts. Companies specializing in these systems can provide design assistance, helping select the appropriate fabric type, mattress thickness, fill material, and anchorage system based on a proper site assessment. They understand the engineering principles involved and can offer Expert Geotextile Mattress Solutions for Erosion Control. Considering the growth in infrastructure projects and environmental protection, highlighted by reports like the United States Geotextile Industry Research 2024-2029 and the overall Global Geotextile Fabric Market, the demand for effective solutions like geotextile mattresses is strong. Getting the right advice ensures you invest in a system that actually works for your specific erosion problem, leveraging the available Services and expertise, like that from knowledgeable individuals mentioned About. Don’t just guess; gettin’ the right advice saves hassle later.

Frequently Asked Questions (FAQ)

Q1: What are geotextile mattresses filled with?

A: Most commonly, they are filled with a flowable concrete grout mix (sand, cement, water). Sometimes, depending on the application, they might be filled with sand, gravel, or even soil for vegetation purposes, though grout is typical for robust erosion control.

Q2: How long do geotextile mattresses last?

A: When properly designed and installed using durable materials, they can last for many years, often decades. The lifespan depends on the quality of the geotextile fabric (especially its UV resistance), the fill material, and the severity of the environmental conditions (like abrasion or chemical exposure).

Q3: Are geotextile mattresses environmentally friendly?

A: They can be considered relatively environmentally friendly compared to some ‘hard armor’ solutions. They use less concrete volume than solid paving, their permeability prevents harmful hydrostatic pressure buildup, and they can be designed to integrate vegetation, creating habitat and a more natural appearance. The synthetic fabrics themselves are inert once installed.

Q4: Can you walk or drive on geotextile mattresses?

A: Once the concrete fill has cured, they form a hard, stable surface. Light foot traffic is usually fine. Vehicle traffic depends entirely on the mattress thickness, fill strength, and subgrade support – heavy vehicle use would typically require specific design considerations and potentially thicker mattresses or sub-base preparation.

Q5: How much do geotextile mattresses cost?

A: The cost varies significantly based on the type of mattress, fabric specifications, fill material, site accessibility, required site preparation, and labour costs in the region. While potentially more expensive per square meter than simple riprap initially, they can be more cost-effective in the long run due to better performance, defined thickness, and potentially lower maintenance, especially when considering the full installation and lifecycle costs. Getting a specific quote based on project details is necessary for accurate pricing. You can reach out for Expert Geotextile Mattress Solutions for Erosion Control.