How Grout Mix Impacts Mattress Durability and Functionality

Key Takeaways:

- Grout is Critical: The grout mix inside a geotextile mattress isn’t just filler; it’s key to the mattress’s weight, strength, flexibility, and overall function.

- Components Matter: Cement provides strength, the water-cement ratio controls flow and final strength, aggregates add weight and bulk, and admixtures fine-tune properties for specific conditions.

- Balance is Key: Getting the mix right involves balancing strength, flowability (for installation), durability, and cost, depending on the project’s specific needs (e.g., erosion control, slope stabilisation).

- Correct Mix = Performance: A well-designed grout mix ensures the mattress installs correctly, stays in place, resists environmental stresses, and lasts a long time. An improper mix can lead to failure.

- Testing is Necessary: You cant just guess the mix. Quality control testing (like flow cone and cube tests) before and during installation is vital to ensure the grout meets the required specifications.

What Exactly is a Geotextile Mattress and Why Does Grout Matter?

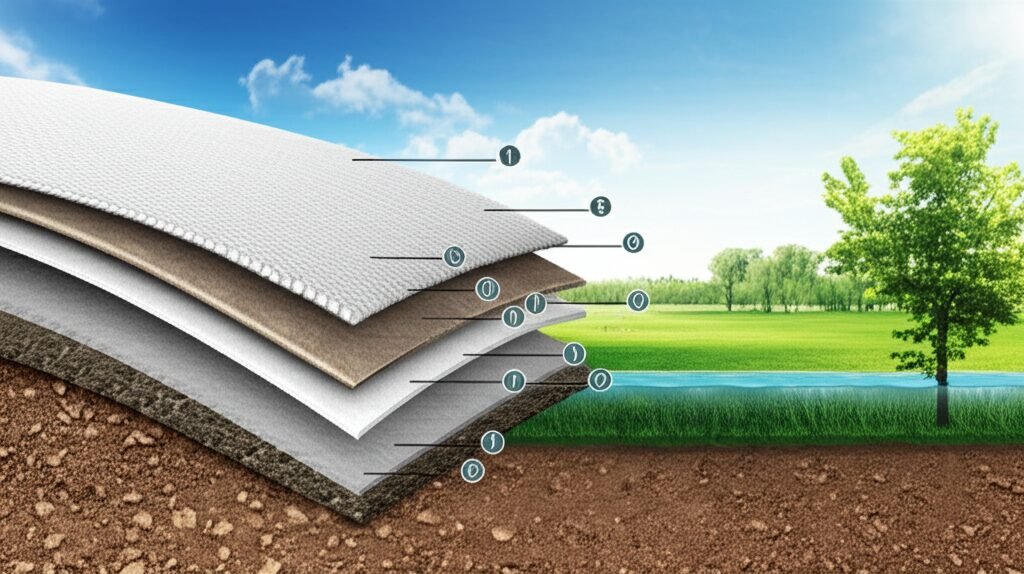

So, what’s a geotextile mattress? Think of it like a big, tough fabric bag, but designed for civil engineering jobs, not sleepin’. These bags, or mattresses, are made from special woven geotextile fabrics. We lay them out on riverbanks, channels, slopes, or underwater sites that need protection from erosion or scour. The real magic happens when we fill ’em up, usually with a cement-based grout. This grout flows into the mattress, fills it out, and then hardens. It gives the whole thing weight, stability, and a solid, protective layer. You can find a good overview in this Geotextile Mattress Uses, Benefits & Installation Guide. The fabric itself does some work, like filtering water in certain designs like Advanced Filtration Geotextile Mattress Systems, or allowing plants to grow through in others like Advanced Vegetation Geotextile Mattress Systems. But it’s the grout that really dictates how the mattress performs long-term.

Now, why is the composition of this grout so important? Well, it directly affects nearly everything about the finished mattress.

- Strength: How much load can it take? Will it resist impacts from debris or ice? The amount of cement and the water ratio are huge factors here.

- Weight/Density: Is it heavy enough to stay put in fast-flowing water or on a steep slope? The type and amount of aggregate (usually sand) plays a big role.

- Flexibility: Can the mattress conform to uneven ground without cracking? A mix thats too stiff might break; one thats too weak wont offer protection. The grout mix needs to allow some flexibility, especially just after placement.

- Durability: How long will it last? Will it stand up to freeze-thaw cycles, chemical exposure, or abrasion from sediment? The quality of the cement, the water-cement ratio, and sometimes special admixtures determine this. You can check out some Proven Geotextile Mattress Projects for Water Infrastructure to see these things in action.

- Pumpability/Flow: Can we actually get the grout into the mattress easily? The mix has to be fluid enough to pump over distances and fill every nook and cranny of the fabric formwork without blockages or excessive pressure. This is where the water content and potentially plasticizers come in. Get this wrong, and the installation is a nightmare, trust me. I remember one job early in my career where the mix was too stiff – we spent more time clearing pump blockages than actually filling the mattresses. Lesson learned the hard way.

So you see, the grout aint just some simple concrete mix. It has to be carefully designed based on the project requirements, the site conditions, and the specific type of durable geotextile mattress being used. Getting the grout composition right is fundamental to the success of the whole system. It’s not just about filling a bag; it’s about creating a functional, long-lasting engineered structure.

The Role of Cement Content in Grout Strength and Durability

The amount of cement in the grout mix is probably the single biggest factor determining its final strength and how long it’ll last. Cement is the binder, the glue holding everything together. Generally speaking, more cement means higher compressive strength. This is crucial cause the mattress often needs to resist significant forces – think fast water currents, wave action, or even impacts from boats or debris. If the grout’s too weak, it might crack or crumble under stress, compromising the entire structure. We’ve seen projects where skimping on cement content led to premature failure, especially in really tough environments. It’s just not worth the saving sometimes. The Fabric Formed Concrete approach relies heavily on getting this right.

Durability is tied closely to strength and cement content too. A denser, stronger grout achieved with a good amount of cement is usually less permeable. This means less water can seep in, which is important for resisting freeze-thaw damage in cold climates. Water gets into pores, freezes, expands, and slowly breaks the grout down. More cement helps create a tighter structure that resists this. It also improves resistance to chemical attack (like sulfates in soil or water) and abrasion from sand or gravel carried by water flow. You want that mattress to last decades, right? Adequet cement content is key, as shown in this Geotextile Mattress Lifespan and Long-Term Performance Guide. Of course, there’s a limit. You cant just dump in massive amounts of cement. Too much can make the grout brittle, prone to shrinkage cracking as it cures, and also unecessarily expensive. Plus, high cement content generates more heat during hydration (curing), which can sometimes be a problem in very large pours or hot weather, potentially stressing the fabric or the grout itself. It’s about finding the sweet spot defined in project specs, like those discussed in A New Specification for Geotextile Grout-Filled Mattresses. The mix design has to balance strength and durability requirements with other factors like cost and the need for sufficient flexibility, especially right after filling. Getting this balance ensures the long-term success seen in many Proven Geotextile Mattress Projects for Water Infrastructure.

Water-Cement Ratio: Finding the Balance for Flowability and Strength

The water-cement (w/c) ratio is maybe the most critical parameter in any grout or concrete mix, and it’s especially vital for geotextile mattresses. This ratio, usually expressed by weight, dictates both the fluidity of the fresh grout and the ultimate strength and durability of the hardened product. Simply put, it’s the amount of water relative to the amount of cement. Get it wrong, and you’re gonna have problems. Too much water makes the grout very fluid, easy peasy to pump, right? Yeah, but it comes at a big cost. Excess water creates more voids (tiny empty spaces) in the grout as it hardens. These voids weaken the final structure significantly. The compressive strength plummets, permeability goes up (making it vulnerable to freeze-thaw and chemical attack), and overall durability surfers. It’s like making a cake with way too much milk – it might be easy to pour, but it wont hold its shape or have the right texture.

On the flip side, if you use too little water (a very low w/c ratio), you’ll get potentially very strong and durable grout, but good luck pumping it! The mix becomes stiff, difficult to handle, and wont flow properly to fill the entire mattress Gaps and voids won’t be filled, leaving weak spots or an incomplete structure. The grout might not even be able to flow through the pump lines without causing blockages. Proper Site Preparation for Geotextile Mattresses: Installation Steps is important, but pointless if the grout cant get where it needs to go. So, the goal is always to use the minimum amount of water necessary to achieve the required workability or flowability for placing the grout correctly. We need enough fluidity for a Flexible Installation: Quick, Simple Setup & Adaptability Guide but not so much that we sacrifice strength and durability. This target w/c ratio is usually determined during the mix design phase and confirmed through testing (like slump or flow cone tests). Often, we use water-reducing admixtures (plasticizers) to increase flowability without adding more water, letting us keep that w/c ratio low for better final quality. It’s a careful balancing act, fundamental to successful Expert Geotextile Mattress Solutions for Erosion Control. An experienced engineer knows how to adjust the mix based on the pump type, distance, ambient temperature, and the specific mattress configuration to hit that perfect balance.

Aggregates: How Sand and Other Fillers Influence Weight and Permeability

While cement and water form the paste that binds and hardens, agregaates – typically sand in grout mixes for mattresses – make up the bulk of the volume. The type, size, shape, and grading (distribution of sizes) of the sand used have a pretty big effect on the final grout properties, especially its density (weight) and, to some extent, its permeability. The primary role of sand is as a filler. It reduces the amount of cement needed (which cuts costs and can reduce shrinkage), and it adds significant weight to the grout. This weight is crucial for the mattress’s stability, helping it resist uplift from water pressure or displacement by currents. A denser grout means a heavier mattress, which is generally better for holding it in place, particularly in demanding applications like riverbank protection or underwater pipeline support. You can see the importance of stability in these Proven Geotextile Mattress Projects for Water Infrastructure.

The characteristics of the sand matter quite a bit. Well-graded sand (a good mix of particle sizes) tends to pack more efficiently, leading to a denser, less permeable grout with fewer voids. Angular sands might create a slightly stronger internal structure compared to rounded sands, but they can also make the mix harsher and less Hhflowable. The maximum size of the sand particles is also critical, especially concerning pumpability. Sand grains that are too large can block pump lines or struggle to pass through the small injection ports sometimes used on mattresses. Generally, for pumpable grout, you want a finer, well-graded sand, often conforming to specific standards outlined in project specifications like the Guide Specification. While the geotextile fabric itself is the primary filter layer in designs like Advanced Filtration Geotextile Mattress Systems, the permeability of the grout itself can still play a role. A less permeable grout (achieved with good aggregate packing and a low w/c ratio) offers better resistance to water penetration and the damage it can cause (like freeze-thaw). However, in some cases, a slightly more permeable grout might be desired to allow for slow drainage, although this is usually managed by the fabric design itself. The key is selecting clean, properly graded sand that contributes the necessary weight and workability without compromising the strength or pumpability needed for the specific project. Its another piece of the puzzle in designing effective Advantages and Applications of Geotextile Mattresses in Erosion Control.

Admixtures: Enhancing Grout Properties for Specific Needs

Beyond the basic ingredients of cement, water, and sand, we often use chemical admixtures to fine-tune the grout’s properties. These are like special ingredients that modify how the grout behaves, both when its fresh and after it hardens. Think of them as tools to overcome specific challenges or enhance performance for particular applications, like needing Specialized Geotextile Protection for Critical Infrastructure. One of the most common types are plasticizers and superplasticizers (also called high-range water reducers). These clever chemicals make the grout much more fluid and pumpable without adding extra water. This means we can keep the water-cement ratio low (which is good for strength and durability) while still getting the flowability needed to easily fill the mattress. Theyre almost essential for achieving high-performance grout thats also practical to install.

Then you’ve got accelerators and retarders. Accelerators speed up the setting time and early strength development of the grout. This can be useful in cold weather to counteract the slowing effect of low temperatures, or when you need the mattress to become stable quickly. Retarders do the opposite – they slow down the setting time. This is helpful in hot weather, giving more time to pump and place the grout before it starts to stiffen, or when pumping long distances. For underwater installations, anti-washout admixtures are incredibly useful. They make the grout more cohesive and viscous, preventing the cement and fine particles from getting washed out by the surrounding water during placement. This ensures the grout maintains its integrity and intended composition even when pumped directly into water-filled environments. Other admixtures might include air-entraining agents (to improve freeze-thaw resistance by creating tiny air bubbles), shrinkage-reducing admixtures, or corrosion inhibitors if reinforcing steel were ever used (which is rare in standard mattresses but possible in some designs). The use of these admixtures allows engineers to tailor the grout mix precisely, much like the advanced formulations seen in products like Prism Ultimate Performance Grout (though that’s a tiling grout, the principle of using admixtures for performance is similar). Selecting the right combination of admixtures requires expertise and understanding of how they interact with each other and the base grout components. Correct use makes challenging installations feasible and enhances the final performance and Geotextile Erosion Control: Mattress Installation & Benefits.

Grout Mix Design and Its Impact on Overall Mattress Function

So, bringing it all together – the cement, the water, the aggregates, the admixtures – how does the overall mix design affect how the Geotextile Mattress works? The simple answer is: profoundly. The mix design is the recipe, and just like baking, small changes in ingredients or proportions can lead to very different results. A mix designed for simple erosion control on a gentle, dry slope will likely be different than one needed for a deep, fast-flowing channel or for supporting a pipeline underwater. For example, the focus might be on achieving sufficient weight and basic durability for slope protection, perhaps using a standard mix. But for the river channel, you’d need higher strength, excellent abrasion resistance, probably anti-washout admixtures if placed underwater, and guaranteed pumpability over potentially long distances. The Advantages and Applications of Geotextile Mattresses in Erosion Control often hinge on getting this specification right.

Consider flexibility. Some mattress designs, like those with raised patterns such as Raised-Pattern Geotextile Mattress Systems Cut Costs 40%, are intended to have defined points of articulation. The grout needs enough strength to be durable, but it also needs to allow the mattress to flex along these lines without widespread cracking, especially during settlement. This might influence the target strength or even the type of aggregate used. Weight is another factor heavily influenced by the mix. For shoreline protection, maximizing weight with dense aggregates might be the priority to resist wave forces. Conversely, for a vegetating mattress on a slope (Advanced Vegetation Geotextile Mattress Systems), the grout needs to be strong enough but perhaps not excessively heavy, allowing for root penetration and conforming to the ground. The entire process is guided by specifications, often detailed documents like A New Specification for Geotextile Grout-Filled Mattresses or a specific project Guide Specification. These documents outline the minimum required performance characteristics – strength, flow, density, etc. – and the mix design must meet or exceed these targets. Ultimately, the grout mix determines if the mattress can be installed efficiently, if it will achieve the required stability and shape, and if it will provide effective, long-lasting protection. A failure in the mix design or its implementation often leads to a failure of the entire system. Investing time and expertise into the grout mix design is crucial for ensuring the mattress performs as intended throughout its service life, contributing to Successful Erosion Control Projects with Geotextile Mattress Applications.

Quality Control and Testing: Ensuring the Grout Meets Performance Specs

Designing the perfect grout mix on paper is one thing; making sure the grout actually delivered and pumped into the geotextile mattresses meets those specs is another ball game entirely. That’s where quality control (QC) and testing come in, and believe me, its absolutely vital. Skipping or skimping on QC is asking for trouble down the line. You need procedures in place before, during, and sometimes after the grouting operation to verify the mix consistency and potential strength. Before pumping even starts, you gotta check the materials – is the cement the right type and fresh? Is the sand clean and properly graded? Are the admixtures correct and within their expiry date? Then comes batching. Whether its mixed on-site or delivered from a batch plant, you need to ensure the proportions are accurate. This is often checked by monitoring batch weights or volumes.

During the pumping operation, the most common and crucial test is checking the grout’s consistency or flowability. This is typically done using a flow cone test (like ASTM C939). You measure how long it takes for a set volume of grout to flow through a standardized cone. This simple test, performed regularly (say, every hour or every certain volume pumped), quickly tells you if the grout’s fluidity is staying within the target range specified in the mix design. If the flow time starts getting too long (mix getting stiff) or too short (mix getting too watery), adjustments need to be made immediately – maybe tweaking water content slightly or adjusting admixture dosage, always checking with the engineer first. We also take samples during the pour to make test specimens, usually cubes or cylinders. These are cured under controlled conditions (or sometimes field-cured to replicate site conditions) and then crushed in a lab at specific ages (e.g., 7 days, 28 days) to determine the compressive strength. This confirms whether the grout is achieving the required strength outlined in the project specifications. It’s the ultimate proof that the mix design and batching were successful. Sometimes, density tests on the fresh grout are also performed to ensure the weight is as expected. All this requires know-how and diligence, the kind of expertise provided by specialists like Li Gang: Expert Geotextile Mattress Manufacturing Leader on the manufacturing side and experienced site engineers during installation. If you have doubts or need specific performance, getting in touch with Expert Geotextile Mattress Solutions for Erosion Control is always a good idea. Consistent testing provides confidence that the installed mattress will perform as designed, protecting shorelines and preventing erosion effectively, as seen in Geotextile Mattresses for Shoreline Protection and Erosion Prevention.

Comparing Performance: Geotextile Mattresses vs Traditional Methods

It’s worth takin a moment to see how these grout-filled geotextile mattresses stack up against more traditional methods, like dumped riprap (loose rock) or cast-in-place concrete paving. How does the performance differ, especially considering the importance of the grout mix we’ve been discussing? Riprap is basically just piles of rock. Its simple, been used forever, but it has drawbacks. Large rocks are needed for high-flow areas, which can be expensive to transport and place accurately, especially underwater. Smaller rocks can get washed away. Over time, erosion can still occur between or under the rocks if not designed with a proper filter layer. Geotextile mattresses filled with a well-designed grout create a continuous, interlocking (if cellular) layer. The weight is distributed more evenly, and the mattress itself acts as the filter layer, preventing soil loss from underneath. The grout’s strength and weight can be tailored precisely, often allowing for a thinner and lighter overall section compared to the required size of riprap for the same level of protection.

Now compare it to poured concrete lining. Conventional concrete is strong and durable, no doubt. But it’s often rigid and prone to cracking due to settlement or temperature changes, especially over large areas. Forming and pouring concrete, particularly on slopes or underwater, can be complex, slow, and expensive. Extensive site preparation is usually needed. Geotextile mattresses offer significant advantages here. They are flexible and can conform to uneven ground, reducing the need for extensive earthworks – a key point touched on in the Site Preparation for Geotextile Mattresses: Installation Steps. The installation is often much faster; you lay the fabric and pump the grout. The mattress formwork itself contains the grout, simplifying placement, especially underwater where traditional forming is tricky. While the hardened grout provides concrete-like protection, the cellular nature of many mattresses allows for some articulation, making them less susceptible to large-scale cracking than a rigid slab. The Geotextile Mattresses vs Concrete: Cost, Durability & Benefits comparison often favors mattresses for installation speed, adaptability to site conditions, and performance in certain environments. The key, again, is that the grout mix must be properly designed and controlled to deliver the strength and durability needed to rival or exceed traditional methods where appropriate. It’s not just fabric; it’s a composite system reliant on that engineered grout fill.

Frequently Asked Questions (FAQs)

Q1: What’s the typical grout mix used in geotextile mattresses?

A: There isnt one single “typical” mix. It really depends on the project. But a common starting point is a mix of Portland cement, fine aggregate (sand), and water, with a water-cement ratio usually between 0.45 and 0.55 by weight. Admixtures like plasticizers are very common to improve flow without adding too much water. The exact proportions are determined by the required strength, pumpability, density, and durability needed for the specific application. Always refer to project specifications.

Q2: Can I use regular concrete mix instead of a specialized grout?

A: Generally, no. Regular concrete mix usually contains coarse aggregates (gravel) which are too large to pump easily through typical grout pumps and hoses, and they definitely wont flow well into the confined spaces of the mattress fabric. You need a fluid mix made with fine aggregates (sand) specifically designed for pumpability and complete filling of the mattress formwork. Using the wrong mix can lead to blockages, voids, and a mattress thats not properly filled or functional.

Q3: How strong does the grout need to be?

A: Again, it varies. Compressive strength requirements might range from as low as 1500 psi (around 10 MPa) for some low-flow applications to over 4000 psi (around 28 MPa or more) for demanding conditions like high-velocity channels or areas subject to impact. The project engineer will determine the necessary strength based on hydraulic forces, potential loads, and desired lifespan, often referencing standards like those mentioned in the A New Specification for Geotextile Grout-Filled Mattresses.

Q4: What happens if the grout mix is too wet or too dry during pumping?

A: If it’s too wet (high w/c ratio), it’ll pump easily but the final mattress will be weaker, less durable, and potentially more prone to shrinkage cracking. If it’s too dry (low w/c ratio and/or not enough plasticizer), it will be difficult or impossible to pump, wont flow properly to fill the mattress completely leaving voids (weak spots), and could cause pump blockages. Getting the consistency right, checked by tests like the flow cone, is critical during installation.

Q5: How does the grout affect the mattress’s flexibility?

A: The grout itself becomes rigid once hardened. However, many geotextile mattresses are designed with internal seams or a cellular structure. These create defined compartments and thinner sections between filled pillows. This allows the overall mattress system to articulate and conform to ground contours or accommodate minor settlement without catastrophic failure, even though the grout within each pillow is hard. The mix design ensures the grout is strong enough to be durable but doesn’t prevent this system-level flexibility.

Q6: Can grout properties be adjusted for environmental factors like cold weather?

A: Yes, absolutely. Admixtures are key here. In cold weather, accelerators can be added to speed up hydration (curing) and gain strength faster, counteracting the cold’s slowing effect. In hot weather, retarders can slow down setting time, allowing more time for placement before the grout gets too stiff. Air-entraining admixtures can also improve resistance to damage from freeze-thaw cycles in cold climates. Consulting with Expert Geotextile Mattress Solutions for Erosion Control can help tailor mixes for specific conditions.