How Geotextile Fabrics Work: Types, Uses, Benefits, Installation

Right then, let’s get to it. Here’s what you need to know ’bout geotextile fabric.

Key Takeaways: Geotextile Fabric 101

- What is it? Geotextile fabric is a permeable textile material, usually made from polymers like polypropylene or polyester. Think of it as a tough, flexible sheet used in soil-related projects.

- Main Types: You got your woven ones (strong, good for stabilization) an’ your non-woven ones (more like a felt, great for filtration and drainage).

- Core Functions:

- Separation: Keeps different soil layers apart.

- Filtration: Lets water through but stops soil particles.

- Reinforcement: Adds strength to soil structures.

- Drainage: Helps water move away from an area.

- Protection: Shields other materials, like liners in landfills.

- Big Uses: Super common in road building, railway construction, erosion control (like with Geotextile Mattress Systems), retaining walls, landfills, and drainage systems.

- Key Benefits: Makes structures last longer, can reduce construction costs by using less aggregate, improves drainage, and is better for the environment sometimes by preventing soil loss.

So, What Exactly is This Geotextile Fabric Stuff?

Alright, so you’ve heard the term “geotextile fabric” thrown around, maybe on a construction site or when someone’s talkin’ ’bout fixin’ up a dodgy slope. But what in the blazes is it, really? Well, it ain’t your grandma’s quilt, that’s for sure. In the simplest terms, geotextile fabric is a special kinda textile, a fabric, but one that’s designed to be used with soil, rock, or any other geotechnical engineering material. Its job? To make things work better and last longer. Most of the time, these fabrics are made from synthetic polymers – think plastics like polypropylene or polyester. These materials are picked ’cause they’re tough, they don’t rot easy, and they can handle bein’ buried in the ground for ages without fallin’ apart. You wouldn’t want your garden weed barrier giving up the ghost after one season, would ya? Same idea here, but on a much bigger, more heavy-duty scale.

Now, these fabrics ain’t all the same. They come in a few main flavors. You got woven geotextiles, which, as the name suggests, are made by weavin’ together individual strands of material, kinda like how denim is made, but much, much stronger. These woven types are real good when ya need a lot of strength, like for stabilizing a roadbed or reinforcing a steep bank. Then there’s non-woven geotextiles. These look and feel a bit more like felt. They’re made by bonding fibers together, either by shootin’ ’em with needles (needle-punched, they call it), heat, or chemicals. Non-wovens are champs when it comes to filtration and drainage ’cause they got lots of tiny pores that let water pass through but keep the soil bits behind. You can even get a good look at the close-up of geotextile fabric texture to see what I mean – it’s nothin’ like your t-shirt material.

The specific makeup, whether it’s polypropylene or polyester, also plays a part. Polypropylene is pretty common ’cause it’s got good chemical resistance and is fairly cheap. Polyester can offer higher strength and better creep resistance, which means it doesn’t stretch out as much under long-term load. It’s all about pickin’ the right tool for the job. You’ll see these fabrics in rolls, big ol’ rolls sometimes, ready to be laid out. I remember one job, we were buildin’ an access road through some real swampy ground. Without a good, heavy-duty woven geotextile to spread the load, our trucks would’ve sunk clean out of sight. That fabric was a lifesaver, or at least, a major budget-saver. It’s this kinda basic understanding that forms the foundation for all the geotextile fabric uses and applications we see today. The science behind it is pretty neat, too, looking at things like tensile strength, permeability, and puncture resistance. Each project has its own demands, so knowing the properties is key.

Why We Even Bother Using Geotextile Fabric: The Big Benefits

So, we know what it is, but why do we actually use this stuff? Is it just some fancy, expensive sheet plastic? Not by a long shot. The benefits of usin’ geotextile fabric are pretty huge, and they often save a lot of headaches and money down the line. Think about it – these fabrics perform some really crucial jobs that would otherwise need a whole lot more dirt, rock, or complex structures. One of the main reasons is simply to transform terrains with durable geotextile mattresses and other geotextile applications, making difficult ground usable and stable.

Let’s break down some of the big wins:

- Separation: Picture this: you’re building a road. You put down a nice layer of gravel (the sub-base) and then your asphalt on top. Over time, with traffic and rain, that soft soil underneath (the subgrade) can mix with your expensive gravel. What happens? Your road gets weaker, ruts form, and you’re lookin’ at costly repairs. A geotextile fabric placed between the soil and gravel acts like a bouncer, keepin’ ’em separate. The gravel stays gravel, the soil stays soil, and the road stays strong. It’s a simple idea, but real effective.

- Filtration: This is a biggie, especially for drainage systems. A geotextile can let water pass through it, but it traps soil particles. So, if you’re buildin’ a French drain or wrapping a perforated pipe, the fabric stops the surrounding soil from cloggin’ it all up. This means your drain keeps workin’ for years instead of gettin’ choked with silt. Some advanced filtration geotextile mattress systems are designed specifically for these high-demand situations.

- Reinforcement: Some geotextiles, particularly the woven ones with high tensile strength, can actually make the soil stronger. Imagine layin’ layers of fabric within a soil slope or an embankment. It acts a bit like rebar in concrete, holdin’ everything together and allowin’ you to build steeper slopes or carry heavier loads than the soil could manage on its own. I’ve seen it used to build retaining walls that are surprisingly strong, just using soil and fabric.

- Drainage: Beyond just filtration, geotextiles can help water move sideways within their plane. This is especially true for thicker, non-woven types. They can collect water and channel it away, preventin’ water pressure buildup that could cause a slope to fail or a wall to push over.

- Protection: Sometimes, geotextiles are used as a cushion. For example, in a landfill or a pond liner, a tough geotextile layer is put down first to protect the waterproof membrane (the geomembrane) from bein’ punctured by sharp stones in the ground. It’s a relatively cheap insurance an’ can save a very expensive liner.

The list of Geotextile Fabrics and their advantages goes on. They can reduce the amount of aggregate needed in road construction, which saves on material and transportation costs. They often speed up construction ’cause they’re relatively easy to install. And in many cases, they’re a more environmentally sound solution than traditional methods, for instance, by preventing erosion and sediment runoff into waterways. It’s not just about a single benefit; it’s usually a combination of these functions that makes geotextiles such a smart choice for so many projects.

Geotextile in Action: Keeping Soil Where It Should Be – Erosion Control

Erosion, eh? It’s a sneaky beast. Wind and water are always tryin’ to carry away valuable soil, whether it’s from a farmer’s field, a construction site, or the banks of a river. This ain’t just messy; it can undermine structures, pollute waterways, and cost a fortune to fix. This is where geotextile fabric really shines, especially when we talk about serious expert geotextile mattress solutions for erosion control. These ain’t just simple sheets; they’re often engineered systems designed to tackle specific erosion problems. One of the big advantages show up when you look into the advantages and applications of geotextile mattresses in erosion control, ‘specially in tricky spots.

Imagine a newly graded slope on a construction project. A heavy rainstorm hits, and poof, half your carefully shaped hillside is now a muddy mess at the bottom. Lay down a geotextile cover, though, and it acts like a protective blanket. It allows water to soak in, reducing surface runoff, and it holds the soil particles in place. Sometimes, you’ll see a geotextile mattress with vegetation for erosion control; these are designed so plants can grow right through them. The roots of the plants then work with the fabric to provide really long-term, natural-lookin’ erosion protection. It’s a smart way to combine the immediate strength of the geotextile with the natural binding power of vegetation.

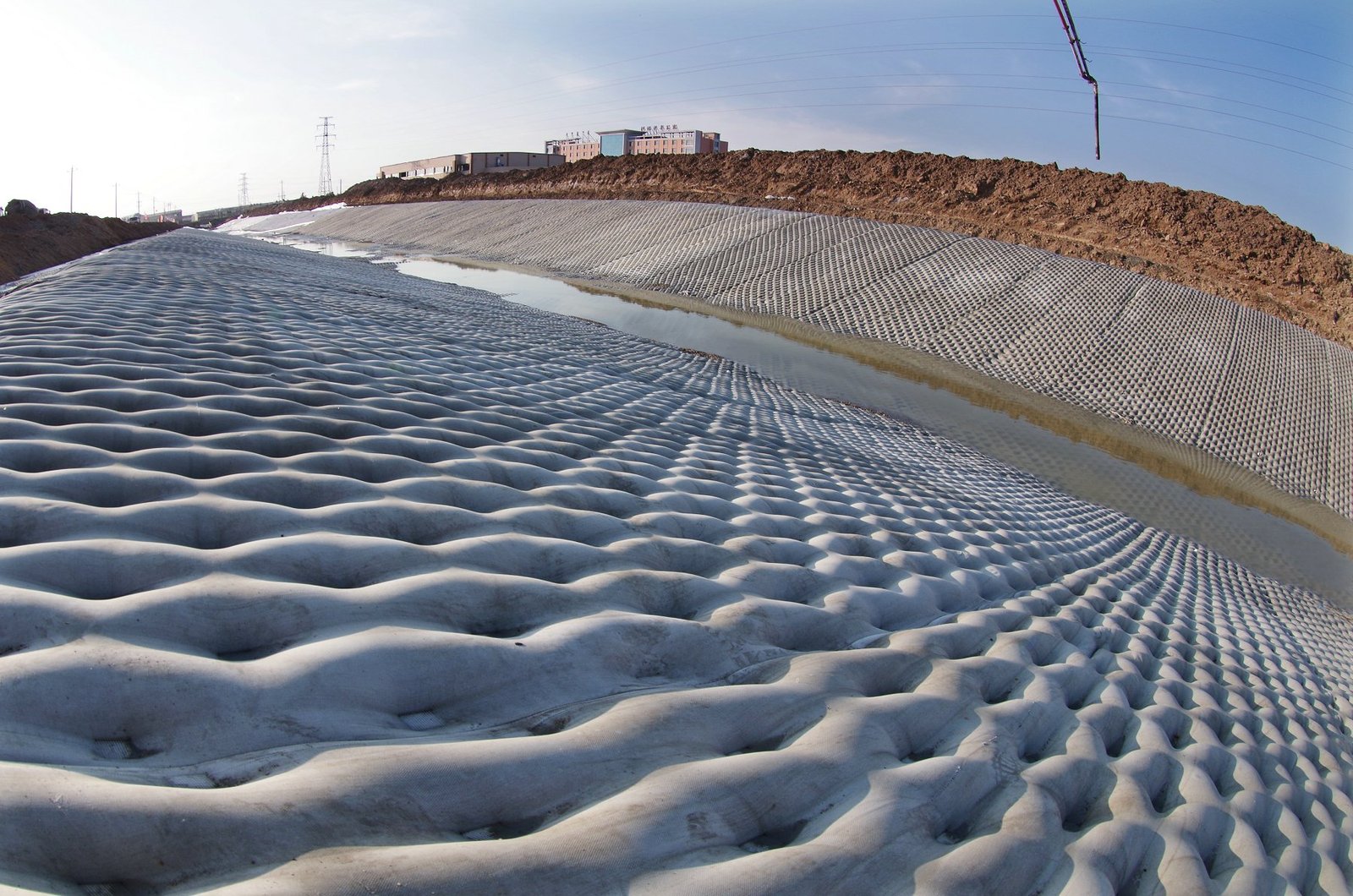

For riverbanks or coastal areas, where wave action and currents are a constant threat, you need somethin’ even tougher. That’s where you might see a large geotextile mattress on slope near coast. These can be filled with sand, grout, or even concrete to create a flexible but very robust revetment. They conform to the shape of the bank, dissipating wave energy and preventing scour. I’ve seen these systems save miles of coastline. The alternative might be dumpin’ tons of rock (riprap), which can be expensive, hard to place, and not always the best for the local habitat. Geotextile mattresses often provide a more engineered and sometimes more aesthetically pleasing solution. They can even make an aerial view of water retention pond with geotextile erosion control look surprisingly neat and tidy, doin’ its job without a fuss. The key is that the fabric allows water pressure from behind the structure to escape, preventing buildup that could otherwise dislodge heavier, impermeable barriers. It’s a delicate balance of strength and permeability.

More Than Just Dirt: Filtration and Drainage Solutions Using Geotextiles

When we talk about keepin’ things dry, or at least managin’ water, geotextiles are absolute champions. It ain’t just about stoppin’ soil from movin’; it’s also about lettin’ water move in a controlled way. This is where the filtration and drainage properties really come into their own. If you’re buildin’ anything that interacts with groundwater or surface water runoff, chances are a geotextile can make it work better and last longer. Think about advanced filtration geotextile mattress systems; these are specifically engineered to handle some pretty tough filtration jobs, keepin’ drains clear and performing optimally for ages.

One classic example is a French drain. You dig a trench, put in a perforated pipe, and backfill with gravel. Simple, right? But what happens over time? Fine soil particles from the surroundin’ earth get washed into the gravel by rain and groundwater, eventually cloggin’ up the spaces between the stones and even gettin’ into the pipe itself. Your drain slowly stops workin’. Now, wrap that gravel and pipe in a non-woven geotextile fabric before you backfill. The fabric acts like a filter. Water can easily pass through it to get to the pipe, but the soil particles are held back. Your drain stays clean and effective for much, much longer. It’s such a simple addition but makes a world of difference. You can even see a worker applying water to geotextile mattress setup, probably testin’ how well the system lets water through while keepin’ everything else stable.

This filtration principle is vital behind retaining walls too. Water pressure buildin’ up behind a wall is one of the main reasons they fail. By placin’ a geotextile against the back of the wall and then using a free-draining gravel backfill, you create a pathway for water to escape. The geotextile stops the soil from the main backfill from cloggin’ this drainage layer. No water pressure, no problem (well, fewer problems, anyway!). According to some good info on Geotextile Filter Fabric: What It Is, Applications, and Benefits, the proper selection of pore size in the fabric is crucial for it to perform correctly without cloggin’ or lettin’ too many fines through. It’s a bit of a balancing act. If the pores are too big, soil gets through. Too small, and it might clog up over time with very fine particles. That’s why there’s a whole science to matchin’ the geotextile properties to the soil type you’re workin’ with. It’s not just any old fabric; it’s an engineered component.

Building Stronger: How Geotextiles Reinforce Our Structures (and Roads!)

Now, let’s talk about makin’ things strong. Geotextiles aren’t just for keepin’ bits separate or lettin’ water through; some types are proper powerhouses when it comes to reinforcement. This means they actually add strength to soil structures, allowin’ us to build things that wouldn’t be possible, or would be a lot more expensive, with just soil alone. It’s a bit like how steel rebar makes concrete way stronger. This is super important when you’re looking at specialized geotextile protection for critical infrastructure, because failure there just isn’t an option. Imagine tryin’ to build a stable road over really soft, squishy ground. Your gravel and asphalt would just sink and disappear.

But, if you lay down a high-strength woven geotextile over that soft subgrade before you put your gravel base course, somethin’ magic happens. The geotextile does a couple of things. First, it acts as that separator we talked about, preventing the good gravel from mixin’ with the muck. Second, and more importantly for reinforcement, it spreads the load from the traffic over a much wider area of the soft soil. This reduces the stress on the weak subgrade, preventin’ it from deforming and causin’ ruts in your road. You end up with a stable road, often usin’ less gravel than you would’ve without the fabric. It’s a win-win. You can sort of visualize this from an aerial view of geotextile mattress installation site – that fabric is foundational to what’s being built on top. Or when you see construction workers installing geotextile mattress, they’re literally laying down the groundwork for a more stable, long-lasting structure.

Another big area for reinforcement is in buildin’ embankments or steep slopes. By layin’ layers of geotextile within the soil as the embankment is built up, you create what’s called a reinforced soil slope (RSS). Each layer of fabric helps to hold the soil together, givin’ it internal strength and allowin’ you to build steeper and higher than you could with unreinforced soil. It’s a very common technique for bridge abutments and approach ramps. I’ve worked on projects where we’ve used this method to save enormous amounts of space because we could go much steeper. The fabric has to have good tensile strength (resistance to pullin’) and good interaction with the soil (it needs to grip the soil well). The long-term performance also matters; you don’t want it stretchin’ out over time (that’s called creep). This is why material selection and proper engineering design are so critical. The overall goal, as pointed out by many in the field, is to improve the stability and load-bearing capacity of soil structures efficiently.

Choosing the Right Fabric: It Ain’t One-Size-Fits-All

Alright, so you’re convinced geotextiles are useful. But here’s the kicker: you can’t just grab any old roll and expect it to do the job. Pickin’ the right geotextile fabric is absolutely critical. It really ain’t a one-size-fits-all kinda deal. Usin’ the wrong type can be as bad, or sometimes worse, than usin’ no fabric at all. You might end up with a clogged drain, a road that still fails, or erosion protection that washes away in the first big storm. That’s why understanding the importance of selecting and using the correct geotextile fabric can’t be stressed enough.

First off, you gotta think about the primary function you need. Is it separation? Filtration? Reinforcement? Drainage? Protection? Or a combination? This will immediately point you towards certain types.

- For separation and reinforcement, especially under roads or for stabilizing slopes, a woven geotextile with high tensile strength and low elongation (it doesn’t stretch much) is often the go-to. These are designed to take stress and spread loads.

- For filtration and drainage, like in French drains or behind retaining walls, a non-woven, needle-punched geotextile is usually preferred. These have good permeability (they let water through easily) and a pore structure that’s designed to retain soil particles without cloggin’ up too fast.

- For some specialized tasks, like promoting plant growth on slopes, you might look at something like vegetation geotextile mattress systems for slope stability. These are designed to hold soil and moisture, givin’ seeds a chance to sprout and establish.

- And then there are systems designed for cost savings, like some raised-pattern geotextile mattress systems cut costs 40% by optimizin’ materials and installation methods for specific applications like channel protection.

Beyond the basic woven/non-woven distinction, you need to look at specific properties. Things like:

- Tensile Strength: How much pullin’ force can it take before it breaks? Measured in different directions too.

- Permittivity/Permeability: How easily does water flow through the fabric?

- Apparent Opening Size (AOS) or Equivalent Opening Size (EOS): This relates to the size of the pores in the fabric and helps determine its filtration capability for specific soil types. You need an AOS small enough to hold back the soil you’re working with, but not so small it clogs instantly.

- Puncture Resistance & Tear Strength: How tough is it against damage during installation or from sharp rocks?

- UV Resistance: If the fabric is gonna be exposed to sunlight for any length of time, it needs to be UV stabilized, or it’ll degrade pretty quick.

I remember a job where a contractor, tryin’ to save a few quid, used a lightweight non-woven fabric meant for landscaping under a temporary construction road. First heavy truck that went over it, the fabric just shredded. Caused a heck of a delay and ended up costin’ more to fix than if they’d used the right heavy-duty woven stuff in the first place. It’s these little details and understanding the material science that separates a successful project from a headache. Always check the specs and, if in doubt, consult with an engineer or a reputable supplier who knows their onions about these materials.

Geotextile Mattress in Practice: Projects and Installation Insights

Talkin’ about geotextiles is one thing, but seein’ them in action, especially the more engineered systems like geotextile mattresses, really shows their worth. These ain’t just bits of fabric; they are often pre-fabricated units that get filled on-site, creating flexible, durable solutions for some tough problems, particularly in and around water. You can see a lot of successful proven geotextile mattress projects for water infrastructure which really showcase the versatility. And if you’re lookin’ to use them, a good Geotextile Mattress Uses, Construction, Benefits & Installation Guide is worth its weight in gold.

Take riverbank protection, for example. You’ve got constant current, potential for flood scour, and maybe even boat traffic. Traditional methods like concrete walls can be expensive, rigid, and not always great for the environment. This is where you’ll often see the installation of geotextile mattress along a waterway. These mattresses, typically made from a double layer of high-strength geotextile stitched into compartments, are laid on the shaped bank and then filled, often with a sand-cement grout pumped in. The result is a flexible, permeable revetment that molds to the bank profile, resists erosion, and allows vegetation to establish if designed for it. Check out these construction workers installing geotextile mattress on riverbank; it’s a common sight on these kinds of projects, showing the hands-on nature of gettin’ these systems in place.

Installation might look straightforward, but it needs care. The ground preparation is key – gettin’ the slope right, smoothin’ out any big bumps or hollows. The mattresses are then laid out, sometimes anchored at the top, and the fill ports are connected for pumpin’ the grout or sand. It’s important to control the fillin’ process to ensure all compartments are filled properly and to the right thickness. You’ll even see a worker in safety gear installing geotextile mattress because, like any construction activity, safety is paramount, ‘specially when workin’ near water or with pumpin’ equipment. One common mistake I’ve seen is inadequate anchoring at the toe of a slope in a channel. If the current can get underneath the mattress, it can lift it. So, proper toe details and sometimes even extra scour protection are needed. Each project is unique, so the design and installation methods have to be tailored. These aren’t just off-the-shelf solutions you can chuck down anywhere; they require a bit of thought and expertise to get the best results.

The Future and Expert Touch: What’s Next for Geotextiles?

Geotextiles have come a long, long way from just bein’ simple filter fabrics. The field is always movin’, with new materials, new designs, and new applications poppin’ up. What’s on the horizon? Well, we’re seein’ a push for even more specialized fabrics, smarter materials, and a greater focus on sustainability and long-term performance. When you have experts like Li Gang: Expert Geotextile Mattress Manufacturing Leader involved, you know that innovation in manufacturing and design is at the forefront, pushing the boundaries of what these materials can do. The range of Geotextile Fabric Uses and Applications is already vast, but it’s set to expand even further.

One area of development is in “smart” geotextiles. Imagine fabrics with embedded sensors that can monitor soil conditions, water pressure, or strain within an earth structure. This could give us real-time data on the health of a levee, a retaining wall, or a road foundation, allowin’ for proactive maintenance before a small problem becomes a big, expensive failure. We’re also seein’ more composite materials, combinin’ geotextiles with other geosynthetics like geogrids or geomembranes in a single, easy-to-install product to tackle multiple problems at once. Think of a geotextile bonded to an impermeable membrane for use in a containment system, providin’ filtration, separation, and a barrier all in one.

Sustainability is another big driver. While many geotextiles are made from plastics, there’s research into more biodegradable options for temporary applications (like short-term erosion control where vegetation will take over quickly) or using recycled polymers in their manufacture. The longevity of traditional polymer geotextiles is actually a big environmental plus in many cases, ’cause a structure that lasts 100 years instead of 20 means less reconstruction, less material usage, and less disruption over its lifespan. The expert touch comes in selecting the right material not just for performance, but also for its overall lifecycle impact. It’s about lookin’ at the bigger picture. I reckon we’ll also see more use in things like green roofs, an’ even in agricultural applications to improve water use efficiency. The adaptability of these fabrics means that if there’s a problem involvin’ soil and water, there’s a good chance a geotextile solution either exists or is just around the corner. The continued research and development by manufacturers and engineers ensures that geotextiles will remain a vital tool for decades to come, helpin’ us build smarter and more resiliently.

Frequently Asked Questions (FAQs)

- Q1: What are the main types of geotextile fabric?

A1: The two main types are woven geotextiles (made by interlacing yarns, good for strength and stabilization) and non-woven geotextiles (fibers bonded by heat, needle-punching, or chemicals, great for filtration and drainage). - Q2: Can geotextile fabric stop weeds?

A2: Yes, certain types of geotextile fabrics, often called landscape fabrics or weed barriers (which are usually non-woven), can be very effective at suppressing weed growth by blocking sunlight while still allowing water and air to reach the soil. However, for heavy-duty civil engineering, the focus is more on their structural and hydraulic properties. - Q3: How long does geotextile fabric last?

A3: It depends on the material (polypropylene, polyester), the application, and the exposure conditions (e.g., buried vs. exposed to UV light). High-quality geotextiles used in civil engineering applications and properly installed can last for decades, sometimes over 100 years, especially when buried and protected from sunlight. - Q4: Is geotextile fabric waterproof?

A4: Generally, no. Geotextile fabrics are designed to be permeable, meaning they allow water to pass through. This is crucial for their functions in filtration and drainage. If you need a waterproof barrier, you’d look for a geomembrane, which is often used in conjunction with geotextiles. - Q5: How do you install geotextile fabric?

A5: Installation varies greatly depending on the application. Generally, it involves preparing the ground surface (clearing debris, leveling), unrolling the fabric, overlapping adjacent pieces (or sewing/welding them for critical applications), and securing it with pins, soil, or other materials. For specialized systems like geotextile mattresses, it involves filling them with grout or sand after placement. - Q6: Can geotextile fabric be used under gravel driveways?

A6: Absolutely! Using a geotextile (usually a woven type for strength and separation, or a heavy-duty non-woven) under a gravel driveway is a very common and effective application. It separates the gravel from the subsoil, prevents the gravel from sinking into the mud, reduces rutting, and improves the driveway’s lifespan. - Q7: What is the difference between geotextile and geogrid?

A7: While both are geosynthetics used for soil reinforcement, geotextiles are fabric-like sheets with functions like separation, filtration, and drainage in addition to reinforcement. Geogrids are more open, net-like structures with large apertures, primarily designed for reinforcement by interlocking with soil or aggregate particles. They offer high tensile strength, particularly in one or two directions.