Seawall Reinforcement with Geotextile Mattress Installation Techniques

Key Takeaways

- Geotextile mattresses are flexible containers made from synthetic fabrics, filled with grout or concrete.

- They are used in seawall construction primarily for scour protection and foundation stability.

- These mattresses prevent erosion at the base (toe) of the seawall caused by waves and currents.

- They conform to uneven seabeds, providing a stable base for the main seawall structure.

- Different types exist, like filtration, vegetation, and raised-pattern mattresses, suited for specific coastal conditions.

- Installation involves placing the empty mattress and then filling it with grout underwater.

- Benefits include flexibility, durability, cost-effectiveness compared to traditional rock armour, and environmental advantages like habitat creation.

- Proper site assessment and selection of the correct mattress type are crucial for success.

What Are Geotextile Mattresses and Why Use ‘Em for Seawalls?

So, what exactly are these geotextile mattresses we’re talkin’ about? Think of ’em like big, tough fabric envelopes, kinda like a really heavy-duty sleeping bag, but made from strong synthetic textiles. These aren’t your bed mattresses, obviously. They’re engineered specifically for civil engineering jobs, particularly near water. The idea is you lay these fabric containers down where you need ’em, and then you pump ’em full of grout, which is basically a fluid kinda concrete mix. Once that grout hardens, you’ve got a solid, flexible slab that molds itself pretty well to whatever surface it’s sittin’ on. It’s a clever way to transform terrains with durable geotextile mattresses (geotextilemattress.com).

Why use them for seawalls, you ask? Well, seawalls have a tough job. They’re constantly gettin’ battered by waves, tides, and currents. One of the biggest headaches for any seawall engineer is scour. That’s when the water action starts digging away the sand or soil right at the base, or the ‘toe’, of the seawall. If that scour gets bad enough, it can undermine the whole structure, leading to instability and potential failure. Not good. Geotextile mattresses are brilliant at preventing this. You lay them down on the seabed right in front of the seawall toe. The hardened mattress forms a protective apron. When waves hit, instead of digging into the seabed, they hit this tough, articulated concrete mat. It shields the underlying soil, stopping scour before it even starts. It’s a foundational piece, sometimes quite literally, for keeping a seawall standing strong for years. We’ve seen projects where without this kind of toe protection, the maintenance costs would’ve been through the roof just a few years down the line. They offer a kind of security hard armour sometimes struggles to provide on certain seabeds.

The Nitty-Gritty: How Geotextile Mattresses Actually Reinforce Seawalls

Alright, let’s get down to the specifics. How do these grout-filled bags actually work to reinforce a seawall? It mainly comes down to two things: scour protection and foundation improvement. As I mentioned, scour at the toe is a seawall killer. The geotextile mattress acts like armour plating for the seabed. The key is its flexibility before filling and its weight and stability after. The fabric itself holds the grout in place while it cures, and the design often includes filter points or fabric layers that allow water pressure to equalize without washing out fine soil particles from underneath. This is crucial. If you just dumped a solid concrete slab, water pressure build-up could lift it or cause erosion around the edges. These mattresses “breathe”, in a manner of speaking. The article “A New Specification for Geotextile Grout-Filled Mattresses” (geosyntheticsmagazine.com) highlights how important getting these properties right is for performance.

The second big way they help is by improving the foundation the seawall sits on, or ties into. Seabeds, especially nearshore, aren’t always perfectly flat or stable. You might have soft spots, uneven rocky bits, or just generally shifty sand. Trying to build a rigid seawall directly on that can be asking for trouble. Differential settlement (where one part sinks more than another) can crack the wall. A geotextile mattress, because it’s laid and filled in place, conforms to these irregularities. It creates a wider, more stable footprint that spreads the load of the seawall above it more evenly. It kinda “smooths out the bumps” and provides a consistent, solid base. This is particularly useful when you’re repairing an existing seawall that’s suffered some undermining, or when building on less-than-ideal ground. It’s a form of specialized geotextile protection (geotextilemattress.com/services/) that adapts to the site conditions, rather than forcing the site to adapt to a rigid structure. We used this approach on a tricky heritage harbour wall repair once; saved a fortune compared to piling.

Types of Geotextile Mattresses Suited for Coastal Defence

Not all geotextile mattresses are created equal, y’know. Different jobs need different specifications. For seawall construction and coastal defence, a few types stand out. One major category involves advanced filtration geotextile mattress systems (geotextilemattress.com/filtration-geotextile-mattress/). These are designed with specific permeability characteristics. The fabric weave and sometimes special filter points allow water to pass through slowly, relieving hydrostatic pressure from behind or below the mattress. This is vital in tidal areas or places with significant groundwater flow. Without proper filtration, water pressure could build up and try to lift the mattress or cause surrounding erosion. These filtration types are often used directly at the seawall toe where wave action and changing water levels are most intense. They need to let water seep out but keep the soil particles in – it’s a delicate balance.

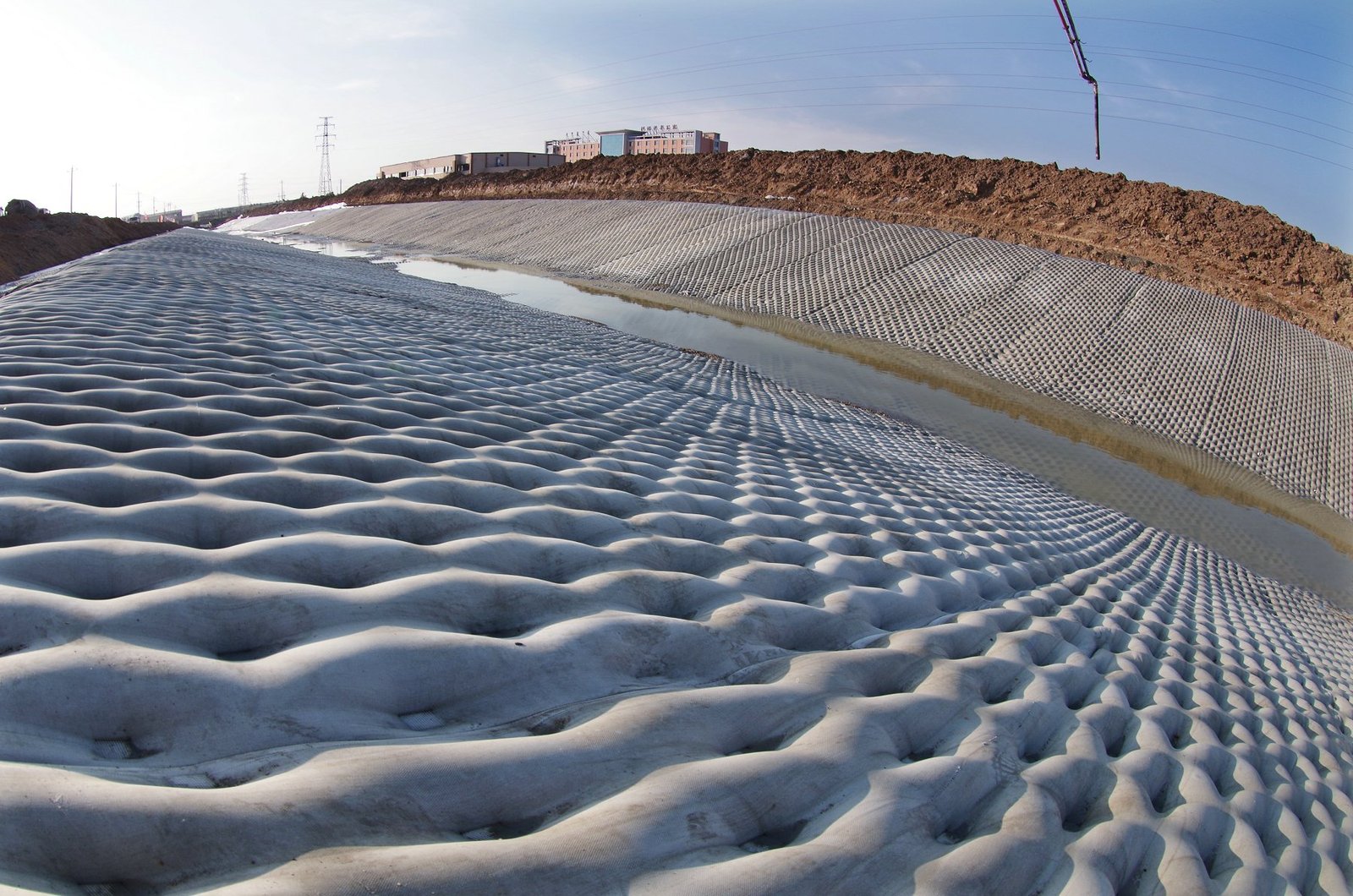

Then you got types designed to work with nature, like advanced vegetation geotextile mattress systems (geotextilemattress.com/vegetation-geotextile-mattress/). These might have pockets or a surface texture designed to trap sediment and encourage marine plants or grasses to take root once the main turbulent energy is reduced. While maybe less common right at the most aggressive wave-break point of a big seawall, they can be great for the upper shore face, behind the main armouring, or in more sheltered estuarine environments where you want erosion control and ecological enhancement. They help blend the hard engineering with a softer, greener transition. Another common type you’ll see are the raised-pattern geotextile mattress systems (geotextilemattress.com/geotextile-mattress/). These have a distinct surface pattern, like ribs or blocks, formed during the filling process. This pattern increases the mattress’s hydraulic roughness, which helps to slow down water flow across the surface and further reduce wave energy compared to a completely flat slab. The raised bits also add a bit more weight and interlocking potential. The choice between these types really depends on the specific wave climate, seabed type, and overall goals of the seawall project.

Installation Know-How: Putting Mattresses in Place for Seawalls

Getting these mattresses installed correctly is key, naturally. It looks kinda straightforward, but doing it right, especially underwater, takes skill and proper planning. First up, you gotta prepare the seabed. This might involve some dredging or grading to get a reasonably level base, removing any big obstacles like boulders or old debris that could damage the fabric or prevent the mattress laying flat. Once the bed’s ready, the large fabric mattress panels, which arrive on site in rolls or folded bundles, are carefully positioned. This usually involves cranes or barges, depending on the scale and location. Divers often play a crucial role here, making sure the panels are aligned correctly, overlapped if necessary, and secured temporarily maybe with pins or weights so they don’t shift before filling.

Next comes the filling part. A grout plant is set up nearby, usually on the shore or a barge. Hoses run from the plant out to the mattress. Special injection points are built into the mattress fabric. The grout, a carefully controlled mix of cement, sand, water, and sometimes admixtures, is pumped through the hoses into the mattress. This needs to be done systematically, often working from the lowest point upwards or from the center outwards, to ensure the mattress fills evenly without trapping air pockets or causing bulges. Divers monitor the filling process, guiding the hoses and checking the fill levels. It’s slow, steady work. Systems like the Triton Marine Mattress System (tensarcorp.com) often emphasize ease of installation, which is a big factor in marine environments. Once filled, the grout needs time to cure and harden, typically 12 to 24 hours before it gains significant strength. After it’s cured, you’ve got your solid, protective layer. Good communication between the dive team, the grout plant operator, and the site supervisor is absolutely essential. You need expert geotextile mattress solutions (geotextilemattress.com/contacts/) providers who understand these marine logistics.

Here’s a simplified look at the steps:

- Site Prep: Clear and level the seabed area.

- Deployment: Position the empty geotextile mattress fabric accurately using cranes/barges and divers.

- Securing: Temporarily fix the mattress position.

- Grout Mixing: Prepare the specified grout mix at the plant.

- Pumping: Pump grout through hoses into the mattress via injection points.

- Monitoring: Divers oversee the filling process for evenness and completeness.

- Curing: Allow the grout to harden fully.

The Upsides: Key Benefits of Using These Mattresses in Seawall Projects

So why go to the bother of using these fabric bags filled with concrete instead of just dumping a load of big rocks (riprap) or building a massive concrete toe beam? Well, there are some pretty solid geotextile mattress uses and benefits (sigaglass.com). One of the main ones is adaptability. As we’ve said, they conform really well to uneven seabeds. Trying to place large rocks accurately on a bumpy surface can leave gaps underneath, which compromises the scour protection. The mattress molds itself, creating a much more continuous barrier. This flexibility also means they handle minor settlement better than rigid structures might.

Another big plus is often the cost and logistics, especially in certain locations. Quarried rock suitable for marine armour isn’t always available nearby. Transporting huge boulders by barge can be expensive and difficult. Geotextile fabric is relatively lightweight and compact to transport. The main bulk material – the grout – can often be mixed on-site using locally sourced sand and cement, reducing transport costs and environmental impact. Installation can sometimes be quicker too, especially compared to painstakingly placing individual armour units. These advantages of geotextile mattresses in erosion control (sigaglass.com) are significant factors when planning coastal projects. From an environmental standpoint, the textured surface and gaps in some mattress designs can actually provide habitat niches for marine life quicker than smooth concrete or large, unstable rocks. Sometimes, vegetation types can even be used to green up the shoreline.

Here’s a quick comparison:

| Feature | Geotextile Mattress | Traditional Rock Armour (Riprap) |

|---|---|---|

| Adaptability | High (conforms to seabed) | Moderate (can leave gaps) |

| Scour Seal | Excellent (continuous barrier) | Good (potential gaps beneath) |

| Transport | Fabric light, grout local sources | Heavy, requires quarry/transport |

| Installation | Can be faster, needs pumping | Placement intensive |

| Foundation | Improves weak ground | Needs stable base |

| Habitat | Can offer niches/vegetation | Limited, depends on rock type |

Real-World Examples: Where Geotextile Mattresses Have Worked Wonders

Talk is cheap, right? Where have these things actually been used successfully for seawalls? The answer is: loads of places. You’ll find proven geotextile mattress projects (geotextilemattress.com/projects/) all over the world, protecting harbours, shorelines, bridge abutments, and pipeline crossings. I recall a project we consulted on a few years back for a marina entrance channel. The currents were fierce during tide changes, and the existing sheet pile walls were showing serious scour problems at the base. Bringing in large enough rock armour was going to be difficult because of access limitations and the depth. We specified grout-filled mattresses laid along the toe line. The installation was done mainly using divers working off a small barge. Within a couple of years, surveys showed the scour had completely stopped, and the mattresses were performing exactly as designed. Saved the marina operator a potential fortune in emergency repairs later on.

They’re also used extensively in riverbank and canal protection, which shares similar principles with coastal defence, just usually with currents rather than waves as the main force. You might see products like ACEFormer™ (geoace.com) or a Geo Concrete Mattress (phuthanhphat.com) used in these settings, which operate on similar principles of fabric forms filled with grout or concrete. For seawalls specifically, they’re often part of a combined defence system. Maybe you have a main seawall structure (concrete, sheet piles, etc.), then the geotextile mattress at the toe for scour, and perhaps rock armour further out to break the main wave energy. It’s about using the right tool for the right part of the job. Seeing aerial views of coastlines where these systems have been installed often shows a clear line of defence holding firm against the water’s edge, keeping the land behind safe and stable. It’s pretty satisfying engineering when you see it working as intended.

Choosing the Right Stuff: Selecting Your Geotextile Mattress

Okay, so you’re convinced they might be useful for your seawall project. How do you choose the right mattress? This is critical. Getting it wrong means it might not perform as needed, or it could fail prematurely. The first thing is a thorough site investigation. What’s the seabed like – sand, silt, clay, rock? How strong are the waves and currents? What’s the tidal range? Is there potential for ship propeller wash? All these factors influence the forces the mattress will need to withstand. That determines the required thickness, weight, and strength characteristics of the filled mattress.

Then you need to look at the geotextile fabric itself. What’s it made of? Usually high-strength polypropylene or polyester. What’s its tensile strength, puncture resistance, UV resistance (important if any part is exposed above water)? What about its filtration properties – will it let water pressure escape without losing soil? This is where specifications come in. Reputable manufacturers provide detailed data sheets. Having people involved who understand manufacturing, like Li Gang: Manufacturing Leader (geotextilemattress.com/about-2/), ensures that the materials meet stringent quality control standards, which is vital for long-term performance in harsh marine environments. You also need to consider the grout mix design. It needs to be fluid enough to pump easily but strong and durable enough once cured to resist abrasion and impact. Sometimes special admixtures are used to improve pumpability or accelerate curing underwater. Thinking about advanced technologies, like those pursued for defense applications mentioned in reports like the one from DTIC (apps.dtic.mil), pushes the boundaries of material science which eventually benefits civil applications too, demanding better, more reliable materials. Selecting the right mattress isn’t just picking one off a shelf; it’s an engineering decision based on site conditions and performance requirements.

Looking Ahead: The Future of Geotextile Mattresses in Coastal Engineering

What’s next for these useful bits of kit? Well, the basic concept is pretty sound, but there’s always room for improvement and innovation. We’re likely to see continued development in the materials used for the geotextile fabric. Stronger, more durable fibers, maybe incorporating recycled materials to improve the sustainability angle. Fabrics with enhanced UV resistance for longer life in exposed areas, or perhaps specialized coatings to deter marine borers in certain environments. Grout technology is also advancing. We might see mixes that cure even faster underwater, or ones that are more resistant to chemical attack in polluted harbour waters, or even self-healing grouts.

Integration with monitoring technology is another area. Imagine mattresses with embedded sensors that can report back on water pressure, temperature, or physical strain, giving asset owners real-time data on the condition of their coastal defenses. This could allow for more proactive maintenance, fixing small problems before they become big ones. There’s also a growing push towards “nature-based solutions.” While mattresses are ‘hard’ engineering, designs that better promote vegetation growth or integrate more effectively with natural reef structures could become more common, blurring the lines between grey and green infrastructure. As sea levels rise and coastal pressures increase, the need for effective, adaptable, and ideally sustainable coastal protection like that offered by durable geotextile mattresses (geotextilemattress.com) is only going to grow. They’ll likely remain a key tool in the coastal engineer’s toolbox for the foreseeable future, hopefully becoming even smarter and greener as technology progresses. It’s a field where practical innovation can make a real difference to protecting communities and infrastructure.

Frequently Asked Questions (FAQs)

Q1: How long do geotextile mattresses last when used for seawalls?

A: Properly designed and installed mattresses using quality materials can last for decades, often 30-50 years or more. Durability depends on the site conditions (wave energy, abrasion), the quality of the fabric and grout, and UV exposure. Regular inspections help assess their condition over time.

Q2: Are geotextile mattresses environmentally friendly?

A: They can be more environmentally friendly than some alternatives. Transporting fabric and mixing grout locally reduces the carbon footprint compared to shipping heavy rock armour long distances. Some designs actively promote vegetation or provide marine habitat. However, they still involve cement production, which has its own environmental impact.

Q3: Can geotextile mattresses be removed or repaired?

A: Repair is possible, though can be tricky underwater. Small damaged areas might be patched with fabric and more grout. Removal is difficult as they form a solid, heavy slab once cured. It would typically involve heavy underwater breaking equipment. Design for longevity is usually the primary goal.

Q4: What is the typical cost compared to rock armour (riprap)?

A: Costs vary hugely depending on location, material availability, site access, and project scale. In areas where suitable rock is scarce or transport costs are high, geotextile mattresses can be significantly more cost-effective. In areas with abundant cheap rock nearby, riprap might be cheaper initially. A full lifecycle cost analysis considering installation, performance, and maintenance is usually needed.

Q5: Can they be used on very steep slopes?

A: Yes, they can be used on steeper slopes than loose rock armour, which relies on interlocking friction. The mattress forms a cohesive slab. However, slope stability calculations are still essential, and anchoring mechanisms might be needed on particularly steep gradients to ensure overall stability.

Q6: Do they work in high wave energy environments?

A: Yes, but the design needs to account for the high energy. This usually means specifying thicker, heavier mattresses with robust fabric and potentially a patterned surface or additional anchoring. They are often used in combination with primary armour like rock or concrete units in the highest energy zones.