Single-Layer vs Double-Layer Mattress Types Comparison Guide

Here are the key things to know quick when thinkin’ about single versus double layer geotextile mattresses:

Key Takeaways: Single vs. Double Layer Geotextiles

- Structure: Single-layer is basically one big fabric bag. Double-layer has two sheets of fabric, often stitched together inside to make pockets.

- Fill Control: Double-layers give you way better control over how thick the final mattress is because of those internal connections. Single layers can bulge a bit if you ain’t careful pumpin’ the fill.

- Uses: Single-layers are often good for simpler jobs, maybe flatter slopes or temporary stuff. Double-layers get used when things are more demanding – faster water, steeper slopes, needin’ a precise thickness or wanting plants to grow through like with Advanced Vegetation Geotextile Mattress Systems for Slope Stability.

- Cost: Single-layer fabric is usually cheaper per piece. But, the total cost might be closer depending on installation labour and how much fill ya use. Sometimes Raised-Pattern Geotextile Mattress Systems Cut Costs 40% which are double-layered, actually save money overall.

- Installation: Singles can be faster to lay out maybe, but need more skill keepin’ the fill even. Doubles might take a bit more handling but filling ’em can be more foolproof for gettin’ the right shape.

What Exactly is a Geotextile Mattress Anyway?

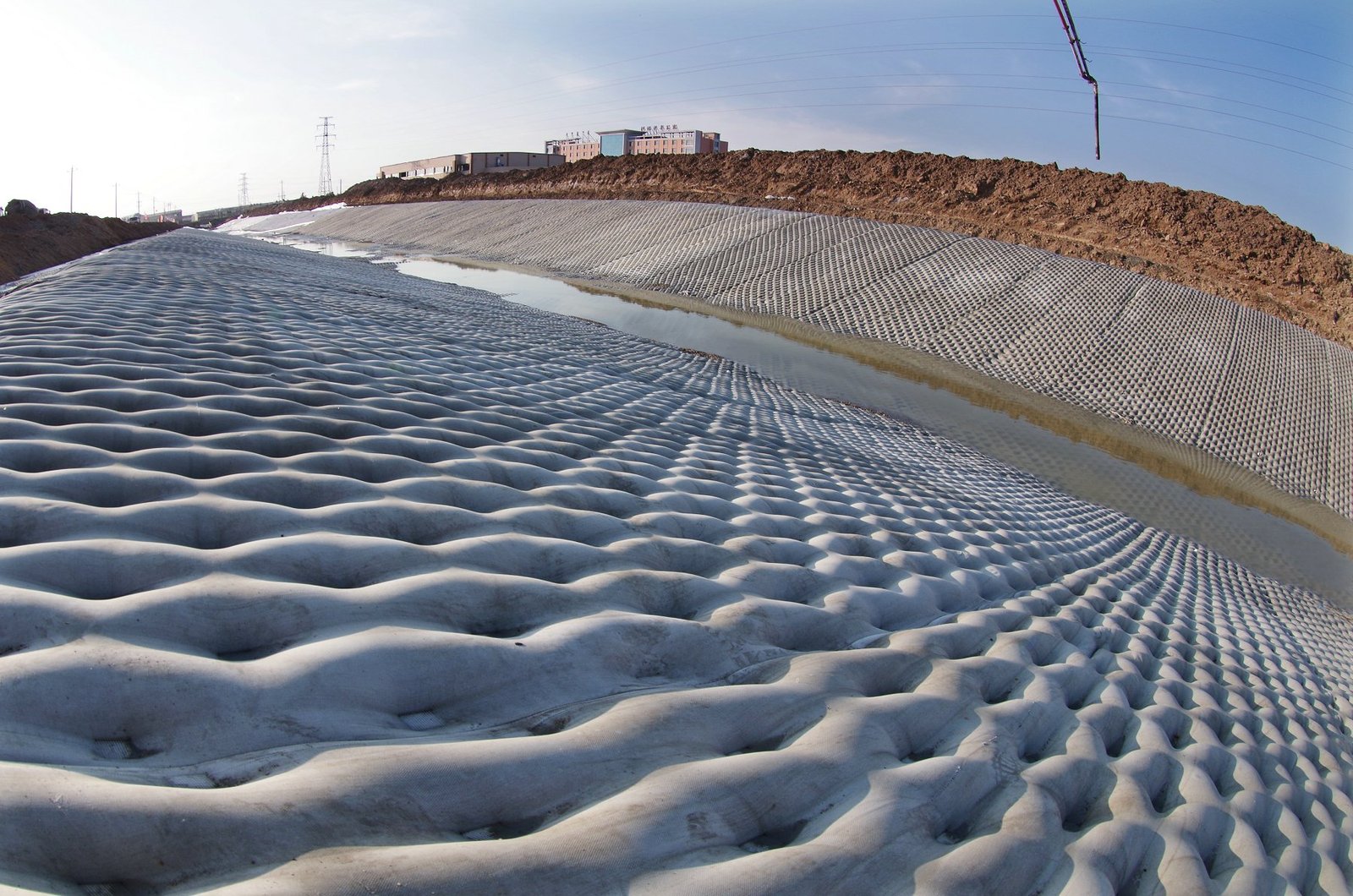

So, what are we talkin’ about here? A geotextile mattress, at its simplest, is a specially made fabric container. Think of it like a big, flat bag made from really tough synthetic fabric. You lay this fabric thing out where you need it – like on a riverbank or the side of a canal – and then you pump it full of something hardenin’, usually concrete or grout. The fabric holds the fill in the right shape while it sets. Its main job? Stopping soil washing away, which engineers call erosion control, or preventing scour, which is when water digs holes around structures like bridge supports. It’s a common tool for Transform Terrains with Durable Geotextile Mattresses.

The fabric itself ain’t just any old cloth. It’s gotta be strong enough to hold the weight of wet concrete, resist tears and punctures durin’ installation, and last a long time when exposed to sun, water, and weather. These are high-strength woven or composite textiles designed specifically for these tough civil engineering jobs. You can get a good overview from this Geotextile Mattress Uses, Construction, Benefits & Installation Guide. The whole point is creatin’ a hard, protective armour layer that stays put and protects the ground underneath. Its way more flexible during install than just dumpin’ rocks (riprap) or pouring a solid slab of concrete, especially underwater or on uneven ground.

Think about those big projects you see sometimes, protectin’ shorelines or stabilizin’ slopes in tricky terrain. Geotextile mattresses are often the unseen heroes there. They conform to the ground’s shape pretty well when you first lay ’em down, which is a big plus. Then, once filled, they form a solid but articulated block. The type of fabric used also matters a lot for things like letting water seep through without washing soil away, a key function in Advanced Filtration Geotextile Mattress Systems. This permeability is important so water pressure don’t build up behind the mattress and cause problems. So yeah, it’s more than just a bag, it’s engineered fabric doin’ a specific job.

Digging into Single-Layer Geotextile Mattress Structure

Alright, let’s look at the single-layer type first. Like the name says, it’s mostly made from just one main layer of geotextile fabric. This fabric is sewn or bonded together to make a large, flat, mattress-shaped container. Sometimes it’s got fill ports, which are basically openings where you stick the hose to pump in the concrete or grout mix. The whole thing is kinda like a giant, empty pillowcase made of super tough fabric before it gets filled.

How’s it work then? Well, you position the unfilled mattress where needed, maybe anchor it down, then pump in the fill. The single fabric layer acts as the mould, containin’ the fluid mix until it hardens. Because there’s no internal structure fixin’ the thickness, the final shape depends a lot on how evenly the fill spreads out inside and the pressure it exerts on the fabric. It can sometimes bulge a bit in places if the fill pressure ain’t managed right durin’ pumpin’. This isn’t necessarily bad, but it means you get less precise control over the exact final thickness compared to a double-layer mattress.

From my experience in the field, single-layer systems can be pretty quick to lay out, which saves some time initially. The simplicity seems appealing. However, the trick is gettin’ that fill placement just right. You need experienced crews managing the pump and maybe movin’ the fill around inside the mattress manually to avoid big lumps or thin spots. If you need specific filtration properties, the choice of that single fabric layer is critical. Some specialised single-layer systems are designed purely for filtration using a specific fabric weave, almost workin’ like a variation of Advanced Filtration Geotextile Mattress Systems, but without the internal ties of a double layer. The fill’s primary job is to provide weight (ballast) and create the overall shape. The fabric does the heavy lifting in terms of containing the fill and providing the interface with the soil and water. For basic jobs, where millimetre precision on thickness ain’t the main concern, they can be a cost-effective way workin’ well. You just gotta understand their limitations regarding shape control.

Understanding the Double-Layer Geotextile Mattress Build

Now, moving onto the double-layer type. This one’s a bit more complex in its makin’. Instead of just one main fabric sheet formin’ a bag, you’ve got two separate layers of geotextile fabric – a top layer and a bottom layer. These two layers are joined together at specific points across the mattress area. The joinin’ is often done with high-strength synthetic yarns or small internal fabric walls called diaphragms. These connections run vertically between the top and bottom sheets.

What do these internal connections do? They’re the crucial bit. When you pump the grout or concrete mix into the space between the top and bottom fabric layers, these internal ties or diaphragms keep the two layers from bulging too far apart. They act like spacers, effectively controllin’ the final thickness of the mattress once it’s filled and hardened. This gives you much more precise control over the mattress profile. You can often specify, say, a 100mm or 200mm thick mattress, and these internal connections ensure that’s pretty much what you get across the whole area.

This controlled thickness is a major benefit, especially for more demanding engineering applications where a consistent and known armour layer weight or profile is needed. Also, the internal connections create distinct pockets or compartments within the mattress. This can add a degree of flexibility if one small area gets damaged – the whole mattress fill ain’t necessarily compromised. Some designs, like the Raised-Pattern Geotextile Mattress Systems, use these double layers and internal connections specifically to create patterns on the surface, like squares or diamonds. This texturing can improve hydraulic performance or help vegetation take root better. Furthermore, you might even use different fabrics for the top and bottom layers. Maybe a tougher, UV-resistant one on top, and one optimised for ground friction on the bottom. This customisation ain’t usually possible with a single-layer type. Build quality, particularly the strength and spacing of those internal ties, is somethin’ I always check specifications for – it directly impacts performance under load.

Key Differences Summarised: Single vs. Double

It helps to see the main differences side-by-side. Gettin’ the right mattress type for the job depends on understandin’ these points. Let’s break it down:

| Feature | Single-Layer Geotextile Mattress | Double-Layer Geotextile Mattress |

|---|---|---|

| Structure | One main fabric layer forming a container. | Two fabric layers (top & bottom) joined internally. |

| Internal Components | None (or minimal, like fill ports). | Connecting yarns or diaphragms controlling thickness. |

| Fill Control | Less precise; thickness varies with fill pressure. | Precise thickness control due to internal connections. |

| Resulting Shape | Can be somewhat uneven or bulbous. | Uniform thickness, can have engineered surface patterns. |

| Installation | Fabric layout might be simpler; fill needs care. | Fabric handling perhaps more complex; filling often easier for consistency. |

| Cost | Generally lower material cost per unit area. | Generally higher material cost per unit area. |

| Common Uses | Gentler slopes, basic protection, temporary works. | Steeper slopes, higher flows, critical protection, vegetation support. |

| Customisation | Limited mainly to fabric type. | Can vary top/bottom fabrics, internal tie spacing/pattern. |

Lookin’ at Comparing Mattress Durability discussions online, even in other mattress contexts, the internal structure often plays a big role in how things hold up over time. While that’s about bed mattresses, the principle applies: a well-structured double-layer geotextile mattress, with its controlled fill and internal reinforcement, tends to provide more predictable long-term performance, especially under stress. However, a properly installed single-layer can still be durable for the right application.

I’ve seen simple single-layer systems used effectively for budget jobs like lining agricultural ditches where the flow ain’t too fierce. But for major channel protection or bridge scour countermeasures? Nearly always see double-layer specified. The engineers want that guaranteed thickness and the robustness that comes with the internal structure. It’s about matching the tech to the risk and requirements of the specific civil engineering project. Choosing cheap when heavy-duty is needed usually ends up costin’ more down the line when it fails prematurely. Readin’ up on the general Advantages and Applications of Geotextile Mattresses in Erosion Control can also give broader context on where these systems fit.

When to Use Single-Layer Mattresses: Best Applications

So, when does it make sense to go for a single-layer geotextile mattress? They definitely have their place. Generally, you’d consider them for situations where the demands ain’t quite as extreme. Think about areas with gentler slopes, where the water flow isn’t tryin’ to rip the bank apart with massive force. They’re often a solid choice when the budget is a primary driver, as the material itself is simpler and usually costs less per square metre compared to double-layer options.

Good examples include:

- Pond Linings: Protecting the banks of storm water retention ponds or farm ponds from wind-wave erosion.

- Simple Ditch Protection: Lining drainage ditches or small canals with relatively low, slow flows to prevent gradual soil loss.

- Temporary Works: Sometimes used for temporary erosion control during a larger construction project before permanent measures are in place.

- Shallow Embankments: Protectin’ the toe or face of low embankments where stability ain’t critically dependent on the mattress itself.

The main things you gotta keep in mind if you’re using single-layer systems relate to the installation and fabric choice. Because there’s no internal structure dictatin’ thickness, the skill of the installation crew pumpin’ the concrete or grout is really important. They need to manage the flow rate and hose position carefully to get a reasonably consistent fill without massive bulges or empty spots. I’ve seen jobs where they had to basically massage the mattress during filling to spread the grout properly – takes time and know-how.

Also, the single fabric layer has to do everything – contain the fill, resist abrasion, maybe provide filtration. So selecting the right fabric specification for the site conditions (soil type, water flow, potential damage risks) is absolutely critical. There’s less margin for error compared to a double-layer system where duties might be split between layers or compensated by the controlled structure. They can work great, but only if applied in the right circumstances and installed properly. They represent a basic, effective tool within the wider range of the Geotextile Mattress Uses, Construction, Benefits & Installation Guide.

Double-Layer Mattresses: Where They Really Shine

Double-layer geotextile mattresses really come into their own when the goin’ gets tough. If you’re dealing with challenging site conditions or need high-performance, long-term protection, this is usually the type specified by engineers, and for good reason. Their controlled thickness and internal structure offer significant advantages in demanding situations.

Think about these scenarios where double-layers typically excel:

- Steeper Slopes: The internal connections help maintain stability and prevent slumping of the fill material on inclined surfaces where gravity is workin’ against you.

- High Water Velocities: In rivers, spillways, or channels with fast-moving water, the consistent thickness and weight distribution of a double-layer mattress provide more reliable resistance against erosive forces and potential undermining. Critical for Proven Geotextile Mattress Projects for Water Infrastructure.

- Scour Protection: Protecting bridge piers, abutments, or pipeline crossings from being undermined by flowing water. The defined thickness and stable profile are essential here. This often involves Specialized Geotextile Protection for Critical Infrastructure.

- Vegetation Support: Some double-layer systems are designed specifically to incorporate topsoil and allow vegetation growth, creating a ‘green’ armour layer. The structure helps hold the soil in place. These are the specialized Advanced Vegetation Geotextile Mattress Systems for Slope Stability.

- Precise Profiles Needed: When the mattress needs to fit snugly under a structure, provide a specific hydraulic roughness, or meet tight design tolerances, the controlled geometry of a double-layer system is invaluable.

Here’s an expert tip from years watchin’ these things go in: pay close attention to the specs for the internal connecting yarns or diaphragms. Their strength, material (polyester, polypropylene etc.), and spacing are critical design elements. I saw one project on a fairly fast river where an underspecified connection system led to localized failures within the mattress pockets under peak flow conditions. The overall mattress held, but the internal structure deformed, which wasn’t ideal. Gettin’ that internal detail right ensures the mattress performs as intended over its full design life. People like Li Gang: Expert Geotextile Mattress Manufacturing Leader understand the importance of these manufacturing details. They might cost a bit more upfront, but for critical applications, the reliability and predictable performance are usually worth the investment.

Installation & Cost Factors: Making the Choice

Deciding between single and double-layer often comes down to balancing installation practicalities and overall project cost. They ain’t quite the same to put in place. Laying out the fabric for a single-layer mattress might seem simpler initially – it’s just one big sheet to position. However, as mentioned before, the skill comes in during the filling stage. Controlling the grout pump pressure and ensuring even distribution within that single large compartment needs care to avoid excessive bulging or thin areas. Double-layer mattresses, with their internal compartments, can sometimes be easier to fill evenly. The compartments guide the grout flow and the internal ties automatically control the thickness. Handling the larger, potentially floppier unfilled double-layer form might require a bit more manpower or careful technique during placement, especially in water or on slopes.

Now, cost. It’s tempting to just compare the price per square metre of the fabric. Single-layer fabric is almost always cheaper than the two layers plus internal connections of a double-layer system. But that’s not the whole story. Consider these points:

- Fill Volume: A single-layer mattress might bulge and actually consume more grout or concrete fill than a double-layer mattress designed for the same nominal thickness, potentially wiping out the fabric cost savings. Some patterned double-layer systems, like the Raised-Pattern Geotextile Mattress Systems Cut Costs 40%, are explicitly designed to reduce concrete volume compared to a flat mattress of the same overall size, offering significant savings there.

- Installation Labour: If filling a single-layer requires more time and skill to get right, labour costs could increase. A potentially quicker, more foolproof fill for a double-layer might offset its higher material price.

- Longevity & Risk: For critical applications, the higher reliability and predictable performance of a double-layer mattress might justify its cost by reducing the risk of failure and future repair expenses. As the Mattress Layers Guide (external link) might imply even for bedding, structure affects durability.

My advice? Don’t make the choice solely on the fabric quote. Look at the total installed cost – fabric, fill material, labour, equipment. And critically, evaluate the project requirements and risks. Is precise thickness needed? Are hydraulic forces high? Is long-term performance paramount? Often, consultin’ with specialists who provide Expert Geotextile Mattress Solutions for Erosion Control can help you weigh these factors and select the most appropriate and genuinely cost-effective solution for your specific site. It’s about getting the best value over the project’s life, not just the cheapest material upfront.

Frequently Asked Questions (FAQs)

Can single-layer be as strong as double-layer?

Strength depends on the fabric used and the fill. A single layer made of very heavy-duty fabric might be strong, but the double-layer structure itself, with controlled fill thickness and internal connections, often provides better overall stability and resistance to deformation, especially under load or on slopes.

Is one better for vegetation?

Double-layer mattresses are often specifically designed for vegetation. Systems like Advanced Vegetation Geotextile Mattress Systems have compartments designed to hold topsoil within the concrete structure, allowing plants to root and create a green finish. This is harder to achieve effectively with a standard single-layer mattress.

How thick can these mattresses be?

Thickness varies. Single layers might range from maybe 75mm (3 inches) up to 200mm (8 inches) or more, but thickness control is less precise. Double layers are typically manufactured for specific thicknesses controlled by the internal ties, commonly ranging from 100mm (4 inches) to 300mm (12 inches), sometimes even thicker for specialised applications.

What’s the lifespan difference?

Lifespan depends more on the quality of materials (fabric type, UV resistance, fill mix) and site conditions (abrasion, chemical exposure, hydraulic forces) rather than strictly single vs. double layer. However, the robust, controlled structure of a double-layer mattress might lead to better long-term performance and durability in demanding environments where inconsistent thickness or bulging could be weak points.

Is installation very different?

Yes, subtly. Laying out single-layer fabric might be quicker. Filling it requires more attention to get even thickness. Laying out double-layer fabric might need more care due to its construction. Filling it is often more straightforward to achieve the designed thickness due to the internal compartments guiding the flow and controlling the shape. Both require proper ground preparation and experienced crews for pumping operations. Need help? Contacting experts for Expert Geotextile Mattress Solutions for Erosion Control is a good idea.