Type 5 Geotextile Fabric Applications Benefits and Installation Guide

Ultimate Guide to Type 5 Geotextile Fabric Use

Key Takeaways

| Aspect | Details |

|---|---|

| Primary Function | Separation, filtration, drainage, and reinforcement |

| Material Composition | Polypropylene nonwoven fabric |

| Best Applications | Drainage systems, erosion control, soil stabilization |

| Installation Benefits | High durability with excellent physical and hydraulic properties |

| Durability | Will last indefinitely once installed underground |

| Resistance Properties | UV resistant, pH stabilized, resistant to rodents and insects |

Understanding Type 5 Geotextile Classifications

Type 5 geotextile represents a specialized classification within the broader geotextile family. While industry standards like AASHTO M288 typically reference Classes 1-4, some manufacturers and regional specifications may use additional type designations including Type 5 for specific performance characteristics.

The classification system can vary between manufacturers and municipalities. The definition of a class or type of geotextile can vary slightly depending on the municipality, DOT or project engineer. This means engineers must always verify that their selected fabric meets specific project requirements rather than relying solely on type numbers.

Most geotextile fabrics in this category share common characteristics: they’re typically nonwoven, manufactured from polypropylene fibers, and designed for specific hydraulic and mechanical performance standards. Understanding these fundamentals helps engineers make informed decisions about material selection.

Material Composition and Manufacturing Process

Type 5 geotextiles are predominantly manufactured using polypropylene synthetic fibers through a needlepunching process. This manufacturing method creates the fabric’s distinctive properties that make it suitable for civil engineering applications.

The needlepunching process involves punching the fabric with sharp, barbed needles creating a random three-dimensional pore structure. This technique produces the material’s characteristic felt-like texture and establishes its filtration capabilities.

Polypropylene offers several advantages as a base material. It’s not biodegradable and will last indefinitely once installed underground. The material also demonstrates excellent chemical resistance, making it suitable for challenging environmental conditions.

The manufacturing process also incorporates UV stabilizers and other additives. These enhancements ensure the fabric maintains its integrity during storage, installation, and long-term service life in various environmental conditions.

Primary Functions and Performance Characteristics

Geotextiles serve four fundamental functions in construction and civil engineering projects. The most common applications include Separation, Stabilization, Reinforcement, Filtration, Moisture Barrier, and Drainage.

Separation prevents different soil types from mixing while allowing water movement. This function proves critical in road construction where base materials must remain distinct from subgrade soils. Filtration allows water passage while retaining soil particles, making it essential for drainage systems.

Drainage facilitates water movement through the fabric structure. With a permittivity rating that allows processing of large water volumes, these fabrics excel in applications requiring efficient water management.

Stabilization works differently from separation by allowing water to seep from soft soil to draining material, consolidating the basement layer and strengthening it. This makes unstable soils more reliable as construction bases.

The performance characteristics depend heavily on the specific weight and construction of the fabric. Lighter weight fabrics excel in filtration and drainage, while heavier versions provide better separation and moderate reinforcement capabilities.

Installation Methods and Best Practices

Proper installation directly impacts geotextile performance and longevity. These fabrics easily conform to ground or trench surfaces for trouble-free installation, but following established procedures remains crucial for success.

Surface preparation ranks as the most critical first step. Remove sharp objects, large stones, and debris that could puncture the fabric during installation. The surface should be reasonably smooth and well-graded to prevent fabric damage and ensure proper contact.

Overlap requirements vary by application and manufacturer specifications. Most installations require 6-inch minimum overlaps at seams, with 12-inch overlaps recommended for critical applications. When sewn seams are required, use thread with strength of at least 25 lb and Federal Type 401 stitch.

Anchoring methods depend on specific site conditions and application requirements. Trenching remains the preferred method for most applications, with 6-inch minimum burial depth in most soils. Alternative anchoring includes stakes, sandbags, or other approved methods for temporary installations.

Quality control during installation includes checking for tears, proper overlaps, and adequate anchoring. Document any repairs or modifications for future reference and warranty considerations.

Applications in Civil Engineering Projects

Type 5 geotextiles find extensive use across diverse civil engineering applications. Road construction represents one of the largest application areas, where these fabrics provide ground stabilization as road construction underlayment.

Drainage applications capitalize on the fabric’s hydraulic properties. These lightweight nonwoven geotextile drainage fabrics excel at filtering stormwater while retaining debris and sediment. This makes them ideal for French drains, foundation drainage, and stormwater management systems.

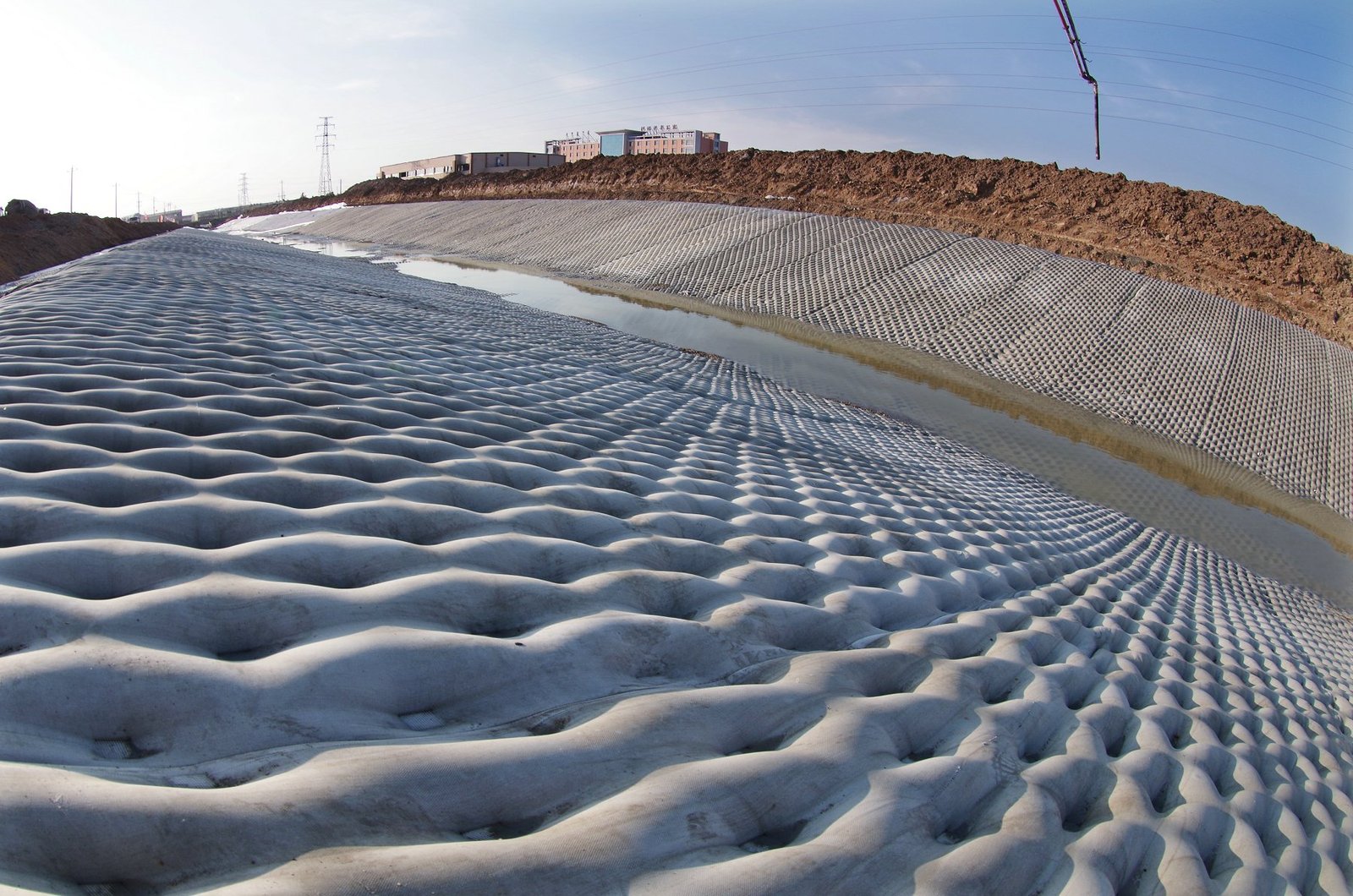

Erosion control projects benefit from the fabric’s ability to strengthen soil and keep banks and slopes intact, limiting erosion effects. This proves particularly valuable in coastal protection, slope stabilization, and streambank restoration projects.

Landscaping applications include use under decorative stone, preventing weed growth while maintaining drainage. The fabric creates an effective barrier that prevents vegetation from growing through rock without creating water collection issues.

For specialized applications, engineers often combine geotextiles with other materials. Geotextile mattress systems provide enhanced erosion protection by integrating fabric with concrete or other protective materials.

Specification Guidelines and Selection Criteria

Selecting appropriate geotextile fabric requires understanding project-specific requirements and matching them to fabric properties. AASHTO M288 covers required strength properties for six standard applications: Subsurface Drainage, Separation, Stabilization, Permanent Erosion Control, Sediment Control and Enhancement.

Key specification parameters include tensile strength, puncture resistance, apparent opening size, and permittivity. Tensile strength determines the fabric’s ability to withstand installation stresses and service loads. High puncture and tear resistance helps fabrics withstand installation stresses.

Apparent Opening Size (AOS) controls the size of particles that can pass through the fabric. The value is obtained by sieving known-diameter glass beads through the geotextile until 5% or less passes through. This specification ensures proper filtration performance.

Permittivity measures the fabric’s ability to allow water flow. Permittivity is calculated as fabric permeability divided by fabric thickness. Higher permittivity values indicate better drainage capabilities.

Environmental considerations include UV resistance for exposed applications and chemical compatibility with site conditions. Most modern geotextiles include UV stabilizers, but specification verification remains important for long-term exposed installations.

Drainage and Filtration Performance

The hydraulic performance of Type 5 geotextiles makes them particularly suitable for drainage and filtration applications. High permittivity properties provide high water flow rates while providing excellent soil retention.

Filtration performance depends on the relationship between soil particle sizes and fabric opening sizes. Properly designed systems allow water passage while retaining soil particles that could clog drainage systems. This balance prevents both soil migration and system failure.

Long-term performance requires consideration of potential clogging mechanisms. Three soil/fabric filtration tests evaluate clogging potential: long-term flow, gradient ratio and hydraulic conductivity ratio tests. These performance tests use actual site soils rather than standardized materials.

Flow rate calculations must account for both fabric properties and installation conditions. Compaction during installation reduces fabric thickness and can impact hydraulic performance. Proper installation techniques help maintain design flow rates throughout the system’s service life.

The fabric’s three-dimensional pore structure contributes to its excellent filtration characteristics. Unlike simple screen-type filters, the complex pore network provides multiple filtration mechanisms that enhance particle retention while maintaining flow capacity.

Cost-Effectiveness and Economic Benefits

Type 5 geotextiles offer significant economic advantages compared to traditional construction methods. These fabrics provide economical solutions to many civil engineering applications including cost-effective alternatives to graded aggregate filters.

Initial material costs represent only a fraction of total project expenses. The fabric’s light weight reduces transportation costs, while easy installation minimizes labor requirements. Fabrics easily conform to ground surfaces for trouble-free installation, reducing installation time and equipment needs.

Long-term economic benefits include reduced maintenance requirements and extended system life. Proper drainage prevents many common infrastructure problems, reducing repair and replacement costs over the system’s lifetime.

Material efficiency contributes to cost savings through reduced aggregate requirements. In many applications, geotextiles allow use of locally available materials that might otherwise be unsuitable without fabric reinforcement or separation.

Project scheduling benefits from the fabric’s all-weather installation capabilities. Unlike some traditional materials, geotextile installation can proceed in various weather conditions, reducing weather-related delays and associated costs.

Future Developments and Innovations

The geotextile industry continues evolving with new materials and manufacturing techniques. Research focuses on enhancing durability, improving hydraulic performance, and developing specialized products for emerging applications.

Sustainability considerations drive development of recycled content fabrics and bio-based materials. While traditional polypropylene remains dominant, alternative materials offer potential environmental benefits for specific applications.

Advanced filtration systems represent one area of innovation, combining traditional geotextiles with specialized components for enhanced performance. These systems address increasingly complex environmental and engineering challenges.

Smart geotextiles incorporating sensors and monitoring capabilities offer potential for real-time performance assessment. These developments could revolutionize infrastructure monitoring and maintenance practices.

Manufacturing improvements focus on consistency and quality control. Enhanced testing methods and quality assurance procedures ensure more predictable performance across different production batches and manufacturers.

Specialized applications continue expanding, with vegetation-enhanced systems and infrastructure protection solutions representing growing market segments. These innovations address specific engineering challenges while maintaining the fundamental benefits of traditional geotextile technology.

Frequently Asked Questions

What makes Type 5 geotextile different from other classifications?

Type 5 geotextile typically refers to a specific manufacturer or regional classification system, as industry standards like AASHTO primarily use Classes 1-4. The specific properties depend on the defining organization’s requirements.

How long does geotextile fabric last in the ground?

Properly installed polypropylene geotextile fabric will last indefinitely underground, as it’s not biodegradable and resists chemical degradation in most soil environments.

Can I install geotextile fabric myself?

While installation is straightforward for small projects, larger installations benefit from professional installation to ensure proper overlap, anchoring, and compliance with specifications.

What weight geotextile do I need for my project?

Weight selection depends on your specific application – lighter weights (4-6 oz) work well for drainage and filtration, while heavier weights (8+ oz) provide better separation and limited reinforcement.

Will geotextile fabric prevent all weed growth?

Nonwoven geotextile provides excellent weed prevention while allowing water and nutrients to pass through, but some aggressive weeds may eventually penetrate if the fabric is damaged or improperly installed.

How do I calculate how much geotextile fabric I need?

Measure your project area and add 10-15% for overlaps and waste. Remember to account for required overlaps at seams and edges for proper installation.