Underwater Geotextile Applications: Benefits and Installation Guide

Okay, let’s talk about puttin’ these geotextile things underwater. It’s kinda interesting how they work down there.

Key Takeaways

- Erosion Control: Geotextile mattresses are brilliant for stopping shorelines, riverbanks, and seabeds from washing away under water.

- Stabilization: They hold underwater structures like pipelines and bridge supports steady, preventing scour.

- Filtration: The special fabric lets water through but keeps soil in place, stopping pressure build-up.

- Flexibility: They can be filled with grout underwater and mould themselves to uneven surfaces.

- Installation: It takes special gear and know-how to put them in right when you can’t see much.

- Cost-Effective: Often a better deal than just dumping loads of rock, ‘specially in tricky spots.

What’s the Deal with Underwater Geotextile Mattresses?

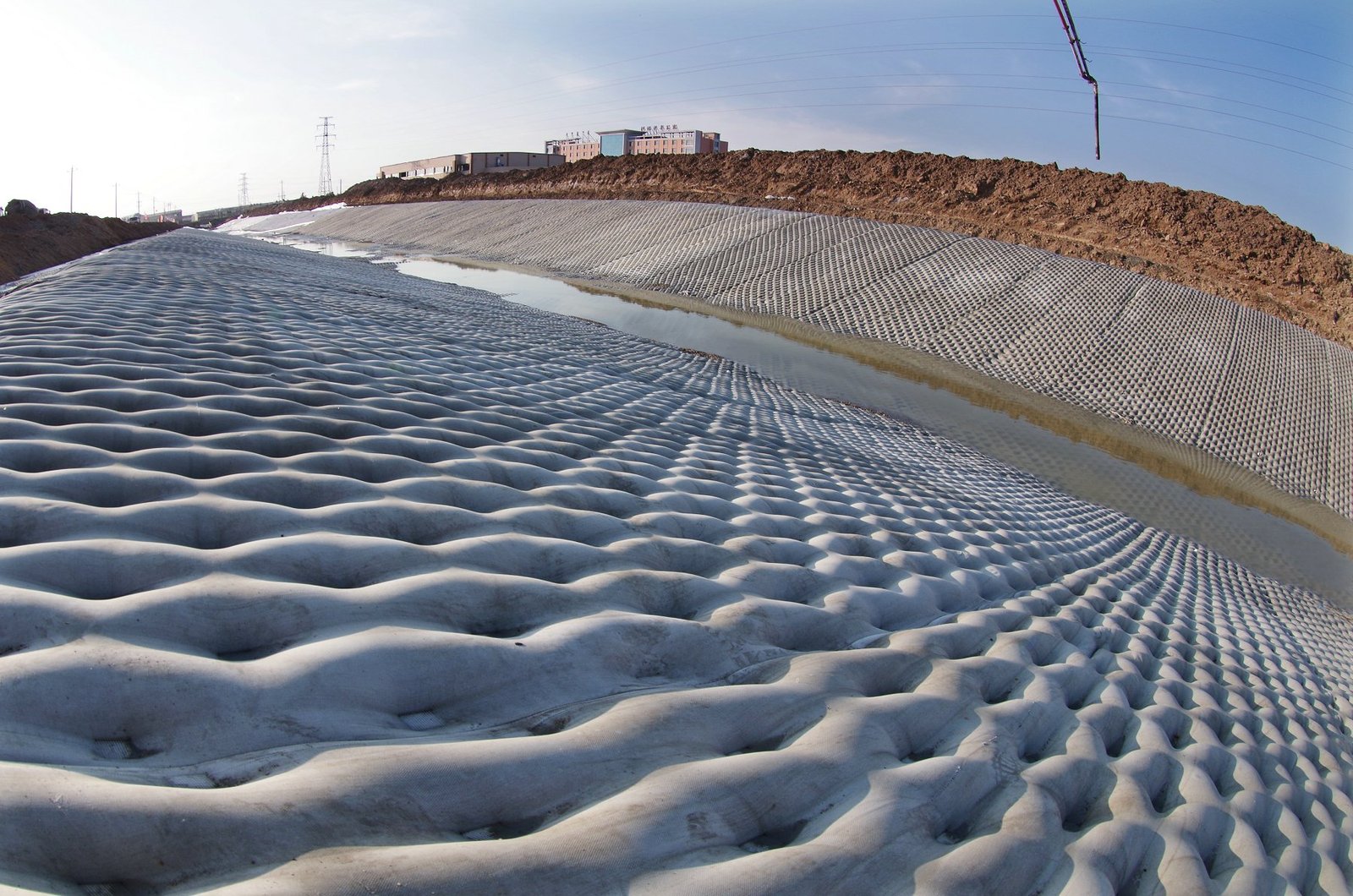

So, what even is a geotextile mattress when we talk about using it underwater? Think of it like a big, tough fabric envelope, sewn together in a specific pattern. You make ’em outta really strong synthetic fabrics, geotextiles they call ’em. The clever part is you sink this empty ‘envelope’ where you need it, maybe on a riverbed or against a harbour wall, and then you pump it full of grout, which is like a runny concrete mix. It fills up all the pockets inside the mattress, making it heavy and solid, but it still fits the shape of whatever it’s lying on. Why bother doing this underwater? Well, water, especially moving water, likes to shift stuff around – sand, soil, you name it. This shifting, erosion, can mess up shorelines, undermine structures like bridge foundations or pipelines laid on the seabed. These durable geotextile mattresses are a way to put a protective layer down that stops the erosion right where it starts.

I remember one job we did, a pipeline crossing a small but surprisingly fast-flowing river. The currents were constantly trying to dig out the soil from underneath the pipe. Just dumping rock, riprap, wasn’t really cutting it, the smaller stones kept washing away. We brought in these geotextile mattresses, laid ’em either side and a bit over the pipe. Pumped ’em full of grout, and bam. Problem solved. The mattress formed this smooth, heavy shield that the current just couldn’t shift, and it held the riverbed material in place underneath. It’s not just about stopping erosion though, it’s about creating a stable base, sometimes for things that haven’t even been built yet. Putting down a mattress can prepare the ground, sorta like laying a foundation underwater. It’s a pretty adaptable bit of kit, really.

The fabrics themselves gotta be tough, resistant to tearing, UV light (even underwater, some gets through), and chemicals they might meet down there. And the way they’re stitched, the pattern of the internal compartments, that’s important too. It controls how the grout flows inside and the final shape and thickness of the mattress. Some designs, like a raised-pattern geotextile mattress, can even offer extra hydraulic performance or friction. It’s a technology that’s come a long way, really, much more sophisticated than just a bag fulla cement. You start lookin’ into the different types and their specific uses, and you see how specialised they can be for different underwater challenges.

Keeping Shorelines and Riverbanks from Washing Away

One of the biggest jobs for these mattresses underwater is protecting shorelines and riverbanks. Think about the sea constantly smashing against a seawall, or a river in flood pushing hard against its banks. All that moving water has energy, and it uses it to pick up bits of soil and carry them off. Do that for long enough, and the land just disappears. It’s a constant battle, especially with changing water levels and more extreme weather these days seemin’ly. What a geotextile mattress does here is provide a tough, flexible, and heavy armour layer right on the surface that’s eroding. It’s laid directly onto the slope of the bank or the base of the shoreline, fitting snugly even if the ground isn’t perfectly smooth.

When it’s filled with grout, it becomes this monolithic slab, but because of the fabric construction, it still has some give. It can handle a bit of settlement underneath without cracking like solid concrete might. This flexibility is key, particularly in dynamic places like river bends or coastal zones. The mattress essentially armors the underlying soil, stopping the water from getting purchase on it. Wave action just washes over the top, river currents flow smoothly over its surface. We often see them used at the ‘toe’ of a slope – that’s the very bottom where the erosion is usually worst. Protecting the toe stops the whole slope above it from slumping down. You can find out more about the advantages and applications in erosion control. Sometimes, companies use other clever geosynthetics too, like the solutions offered by Sarmac, which focus on reinforcing the soil itself, often working together with surface protection like mattresses.

The installation underwater needs care, naturally. You gotta place the mattress accurately, make sure it’s sitting flat without big wrinkles before you pump the grout. Divers often guide the placement, especially in deeper or murky water. Once filled, it’s pretty much maintenance-free, which is a big plus compared to constantly having to top up eroded rock armour. We’ve seen these things last for decades, doing their job quietly beneath the waves or river currents. It’s impressive how effective such a relatively simple idea – fabric bags filled with grout – can be in fighting the power of water. Many proven geotextile mattress projects show just how well they work for protecting water infrastructure like this.

Holding Underwater Structures Steady

Right, so protecting banks is one thing, but what about stuff in the water? Pipelines carrying oil, gas, or water across seabeds or riverbeds, the foundations of bridges sitting in the middle of a river, offshore wind turbine bases, communication cables… all these structures face a big problem underwater: scour. Scour is when the water flow, currents or waves, digs out the sediment from around the base of a structure. If it digs out too much, the structure can become unstable, unsupported. A pipeline might sag and break, a bridge pier could tilt. It’s proper serious stuff. Geotextile mattresses are a top solution for preventing this kinda scour.

How do they work here? Well, you basically lay the mattresses around the base of the structure you want to protect, or sometimes right underneath a pipeline before it’s even laid (or you can place ’em carefully around an existing one). When filled with grout, they form a wide, heavy apron. This apron shields the seabed or riverbed immediately next to the structure from the erosive force of the water. The current might still be strong, but it flows over the mattress instead of digging into the soil. It effectively extends the footprint of the foundation, spreading the load and preventing that localised digging action. For pipelines, they can be laid over the pipe too, adding weight to keep it in place as well as preventing scour from undermining it. It’s all about providing specialized geotextile protection for critical infrastructure.

I worked on a project protecting bridge piers in a tidal estuary. The currents switching direction with the tides were just murder on the riverbed around the pier bases. Every few years, they had to bring in barges of rock to dump around them, cost a fortune. We came in and designed a mattress layout that covered a wide area around each pier. Divers helped position the empty mattresses, tricky work with the tides, then we pumped them full from a barge. The difference was huge. The mattresses settled onto the riverbed, formed this smooth, tough surface, and the scour just stopped. Years later, inspections show they’re still doing the job perfectly. It shows how effective these systems are for long-term stabilisation, much better than just chucking loose material down there sometimes. You need expert solutions for this kinda erosion control.

Letting Water Through: The Magic of Filtration

Okay, so these mattresses form a solid, heavy barrier when filled with grout. But here’s a clever bit that sometimes gets missed: the fabric itself, the geotextile, plays a vital role even after the grout sets. It’s not just a bag to hold the concrete mix; it needs to act as a filter. Why’s that important underwater? Well, think about the ground underneath the mattress. Water is still going to be in that soil, and water pressure can build up, especially if you got fluctuating water levels like tides or changing groundwater flow. If you just put a totally solid, impermeable slab (like plain concrete) on top, that water pressure from underneath has nowhere to go. It could build up enough force to actually lift or damage the protective layer itself. Not good.

This is where the geotextile fabric comes in. Good quality geotextiles used for mattresses are designed to be permeable. They have tiny openings, pores, that are big enough to let water molecules pass through relatively easily, but small enough to stop soil particles from washing out from underneath. It’s a balancing act. Let the water pressure dissipate, but hold the soil firm. This filtration function is absolutely critical for the long-term stability of the mattress and the structure it’s protecting. Without it, you could solve the surface erosion problem but create a whole new issue with hydrostatic pressure. These are proper advanced filtration geotextile mattress systems.

Choosing the right fabric is real important here. The size of the pores (called the Apparent Opening Size, or AOS) needs to match the type of soil underneath. Too big, and fine soils wash out. Too small, and the water can’t get through fast enough, and pressure builds up. You also need enough pores over the area (the permittivity or flow rate) to handle the expected amount of water trying to get through. Engineers look at the soil data and the site conditions – like how quickly water levels change – to pick the right fabric specification. It’s a bit technical, but getting the filtration right is just as important as getting the grout strength right for underwater success. There’s even ongoing work on developing new specifications for geotextile grout-filled mattresses to ensure these properties are consistently met.

Filling ‘Em Up: Underwater Grouting Explained

So you’ve got your big fabric mattress positioned perfectly on the seabed or riverbank. Now what? You gotta fill it with grout, and doing that underwater has its own set of tricks. The grout itself is usually a mix of cement, sand, water, and maybe some additives to make it flow nicely or set quicker. The key is getting it inside the mattress without it just washing away in the water before it sets. The mattress fabric helps here – it contains the grout, but remember those filtration pores? They’re small enough that the cement and sand particles generally don’t escape through the fabric, though some very fine cement ‘bleed’ can happen initially, which is normal.

The pumping operation is usually done from a barge or the shore. A hose runs down to special filling ports built into the mattress. You start pumping the grout in, and you gotta control the pressure carefully. Too much pressure, you could burst the fabric seams. Too little, and the grout might not flow properly to fill all the corners and compartments inside the mattress design. Often, the mattresses have internal seams or ‘baffles’ sewn in, which create channels and compartments. This helps control the grout flow and ensures a uniform thickness across the whole mattress. Watching it fill underwater (if the visibility’s good enough!) is quite something – you see the flat fabric slowly plump up and become this solid-looking structure. It’s a neat example of how geotextile mattress technology has evolved.

One of the big benefits of this underwater filling method is that the mattress naturally conforms to the shape of the ground it’s lying on before the grout sets hard. If the seabed is a bit lumpy or uneven, the flexible fabric drapes over it, and the grout fills the voids. This creates really good contact between the mattress and the underlying soil, which is important for stability and preventing under-scour. Compare that to trying to place big, rigid precast concrete blocks accurately underwater – much harder and often leaves gaps. This flexibility makes grout-filled mattresses ideal for lots of underwater protection jobs. Some systems like Techrevetment Formed Concrete Mattresses offer similar formed-in-place benefits but might use different forming fabrics or techniques. The end result though is a tough, durable, custom-fitted protective layer.

Greener Options and Underwater Habitats

When you’re putting stuff underwater, you gotta think about the fishies and the plants too, right? Traditional methods like just dumping loads of rock (riprap) can sometimes create harsh environments, not much room for life to get a foothold. Geotextile mattresses, depending on the design and location, can actually offer some environmental upsides, or at least minimise the impact compared to alternatives. Some designs are specifically made to encourage life.

For example, you can get vegetation geotextile mattress systems. These are designed so that once the grout is set, there are still pockets or areas within the mattress structure where soil can be placed, or where sediment naturally collects. Then, aquatic plants can start to grow in these pockets. This is great for riverbanks or shallower shoreline areas. The plants help stabilize the bank even more with their roots, they provide habitat for insects and small fish, and frankly, it just looks a lot nicer and more natural than bare concrete or rock. The mattress provides the main erosion protection, but the vegetation adds that extra ecological and aesthetic layer. It’s about working with nature a bit more.

There’s also research and development happening into using more sustainable materials. While most geotextiles are synthetic polymers (like polypropylene or polyester), derived from oil, there are efforts to create geotextiles made from renewable raw materials. Think plant-based fibres or recycled materials. The challenge is making these materials strong enough and durable enough to last for decades underwater, but it’s definitely an area the industry is looking at. Even with standard materials, the fact that mattresses can be manufactured relatively efficiently and installed precisely, potentially using less overall material volume than dumping tonnes of rock, can have environmental benefits in terms of carbon footprint and resource use. It’s not always obvious, but the engineering choices here can link back to broader environmental goals.

Gettin’ ‘Em In Place: Underwater Installation Insights

Putting these mattresses down where you want ’em underwater isn’t always a walk in the park. It takes specialist kit and people who know what they’re doing. One of the biggest challenges, obviously, is you often can’t see very well! Murky water, currents, depth… it all makes placing a large sheet of fabric accurately quite tricky. You rely heavily on positioning systems (like GPS on the support vessel), acoustic positioning for divers or ROVs (Remotely Operated Vehicles), and careful planning before you even start. You need to know the exact contours of the seabed or riverbank you’re covering.

Deployment methods vary. Smaller mattresses might be rolled up, lowered down, and then unrolled by divers. Larger ones are often ‘folded’ in a specific way (like an accordion) onto a deployment frame. This frame is lowered to the seabed, and then the mattress is unfolded from the frame in a controlled way. This helps prevent it from just drifting off in the current before it’s secured. Once its roughly in place, divers (or sometimes ROVs in deep water) make the final adjustments, making sure it’s flat, overlapping correctly with any adjacent mattresses, and anchoring the edges temporarily if needed before grouting starts. The whole process is detailed in resources like this geotextile mattress uses, construction, benefits & installation guide.

Currents are a major factor. Trying to handle a large, flexible piece of fabric in moving water is hard work. You have to plan the installation around tide cycles or periods of lower flow if possible. The grout pumping itself also needs careful management. The grout hose needs to be handled correctly so it doesn’t get snagged or damaged. You need to monitor the filling process to ensure all parts of the mattress fill evenly. Sometimes, divers will ‘walk’ the mattress during filling to help distribute the grout. Despite the challenges, experienced crews make it look smoother than it is! And the results, a perfectly placed and filled mattress providing long-term protection, are worth the effort. Using these systems can actually lead to significant cost savings compared to traditional methods, especially when you factor in the longevity and reduced maintenance.

How Do They Stack Up? Comparing Underwater Options

So, geotextile mattresses sound pretty good for lots of underwater jobs, but are they always the best choice? Like anything in engineering, it depends on the specific situation. You gotta weigh ’em up against the alternatives. The most common alternative, especially for shoreline and bank protection, is probably riprap – just dumping large angular rocks. Riprap is simple, been used for ages, and can be effective. But, it has downsides. You need a lot of rock, which means quarrying, transport costs, and a big environmental footprint. Placing it accurately underwater can be tricky, and smaller rocks can get washed away in strong currents, meaning you need bigger, heavier, more expensive rock, or regular top-ups.

Geotextile mattresses, on the other hand, use much less material volume typically. The fabric is relatively lightweight to transport, and the grout can often be mixed using local sand and cement. They provide a smooth, hydraulically efficient surface, which can be better than rough riprap in some situations (less turbulence). The flexibility means they cope better with minor settlement than rigid structures. They often end up being more cost-effective, especially in deeper water or remote locations where getting massive amounts of rock is difficult or expensive. You also have options like Geo Concrete Mattresses, which might use slightly different forming techniques or cellular structures within the mattress.

Then there’s solid concrete structures – things like precast concrete blocks or interlocking units, or even poured concrete walls. These are very strong and durable, absolutely. But they are rigid. If the ground underneath settles even slightly, they can crack or get undermined. They are also heavy and difficult to install accurately underwater, often requiring heavy lifting equipment. Geotextile mattresses offer that advantage of flexibility and conformability that rigid systems lack. It really comes down to the site conditions, the level of protection needed, environmental considerations, and of course, the budget. Having experts involved, like our team led by people such as Li Gang, helps clients choose the right solution. If you need advice for a specific project, it’s always best to get in touch with specialists.

Frequently Asked Questions (FAQs)

Q1: How long do geotextile mattresses last underwater?

A: Properly designed and installed geotextile mattresses can last for decades. The high-strength synthetic fabrics are resistant to rot, chemicals, and UV degradation (though less UV gets underwater). The grout fill is essentially concrete. Lifespans of 30-50 years or more are commonly expected for many underwater applications.

Q2: Can geotextile mattresses be used in really deep water?

A: Yes, they can be and are used in significant depths, often for pipeline protection or stabilization of offshore structures. Installation becomes more complex, usually requiring ROVs (Remotely Operated Vehicles) instead of divers for placement and monitoring, along with specialized deployment frames and pumping equipment rated for the pressure at depth.

Q3: Are they bad for the environment underwater?

A: Generally, they’re considered a lower-impact solution compared to things like large-scale rock dumping. The materials are mostly inert once installed. Some designs, like vegetation mattresses, can actually enhance habitat. The main potential impact is during installation (temporary turbidity from grouting bleed-off), but this is usually localised and short-term. There’s also growing interest in using geotextiles from renewable sources.

Q4: What happens if a geotextile mattress gets damaged underwater?

A: Minor surface abrasion usually isn’t a big deal, as the grout core provides the main structure. If a significant tear or puncture occurs before grouting, it would need patching (often by divers) before filling. If damage occurs after the grout has set (e.g., from a ship anchor strike), the affected area might need repair, perhaps by placing a smaller patch mattress over the top or using other underwater concrete repair techniques, depending on the severity.

Q5: Is it expensive to use geotextile mattresses underwater?

A: The upfront cost might sometimes seem higher than just dumping cheap rock, but you gotta look at the whole picture. Mattresses often require less total material volume, can be faster to install in some cases, and have very low maintenance needs. Their flexibility and effectiveness in preventing scour can save huge costs down the line by protecting valuable infrastructure. Especially in challenging locations (deep water, strong currents, remote areas), they often prove to be the most cost-effective long-term solution for erosion control and stabilization.